Pourquoi les compteurs de point de rosée des sécheurs sont-ils essentiels pour les systèmes d'air comprimé ?

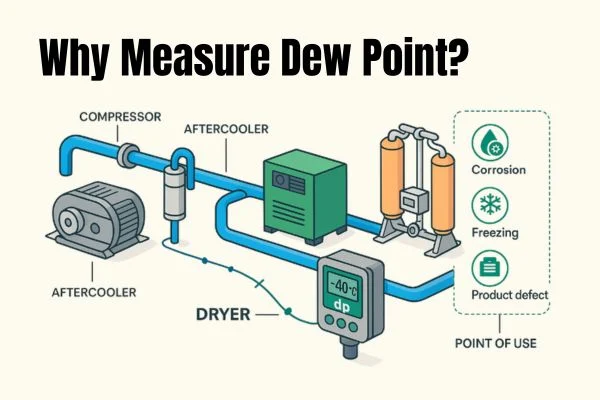

Maybe You always battle hidden moisture in compressed air that can cause corrosion, freezing, and product defects. By installing dew point meters, you detect and stop moisture issues before equipment fails.

You can monitor dew point to prevent condensation and protect assets. The HENGKO HG970 series provides continuous dew point readings with 4–20 mA and Modbus RTU outputs, onboard logging, and diagnostics—so you can close the loop for control and energy savings.

Here, this guide explains the causes of moisture, how to choose sensors, where to place them, and how to integrate the HENGKO HG970 so you can act quickly and reduce risk.

Why Measure Dew Point?

Q1: What exactly are you measuring?

A: Dew point is the temperature at which water vapor in your compressed air will condense into liquid. Knowing dew point tells you when and where condensation will occur as air cools along the line.

Q2: What goes wrong if you ignore dew point?

A: Moisture triggers corrosion, fouling, freeze-ups, and product contamination. Typical impacts:

| Risk | What You See in the Plant | Cost/Impact | Early Warning via Dew Point |

|---|---|---|---|

| Pipe & valve corrosion | Rust flakes, seized valves | Leaks, pressure loss, unplanned shutdowns | Rising baseline dp |

| Pneumatic wear & sticking | Cylinder pitting, actuator stiction | Inconsistent positioning, quality drift | dp spikes during load peaks |

| Freeze in cold zones | Icing at outdoor/underground runs | Line blockages, safety events | dp approaching ambient T |

| Product contamination | Water in coatings, electronics, food/pharma lines | Scrap, recalls, audit findings | dp excursions above spec |

Q3: Where should you place sensors to catch problems early?

A: Measure after dryers, before long/cold runs, and at critical points of use:

| Location | Why Here? | What You Learn |

|---|---|---|

| Outlet of dryer | Validate dryer performance | Is the dryer meeting spec? |

| After main receiver | Check re-evaporation/drain function | Is storage adding moisture back? |

| Start of outdoor/underground header | Predict cold-zone condensation | Do you need lower dp or heat trace? |

| Critical tools/process skids (POU) | Protect quality-sensitive users | Is local treatment working? |

Q4: How do you use trends (not just snapshots)?

A: Continuous logging lets you spot slow dryer decline, tower-switch spikes, and seasonal effects. A simple approach:

| Trend Pattern | Likely Cause | Action |

|---|---|---|

| Gradual baseline rise | Fouled prefilter, saturated desiccant | Inspect drains/filters; schedule regeneration |

| Periodic sharp spikes | Twin-tower switching | Verify purge/valve timing; add alarm delay |

| Night/weekend dp increase | Low flow regeneration inefficiency | Adjust DDS or idle strategy |

Q5: How should you set alarms without creating nuisance trips?

A: Use thresholds with hysteresis and time delay:

| Dryer Type | Typical Spec Target | Alarm Threshold (suggested) | Hysteresis | Delay |

|---|---|---|---|---|

| Refrigerated | +2…+5 °C dp | ≥ +7 °C dp | 1 °C | 60–180 s |

| Desiccant (-40) | ≤ -40 °C dp | ≥ -35 °C dp | 2 °C | 60–180 s |

| Desiccant (-70) | ≤ -70 °C dp | ≥ -65 °C dp | 2 °C | 60–180 s |

Q6: What do you do when alarms occur?

A: Follow a short, repeatable checklist:

| Step | What to Check | Pass/Fail Gate |

|---|---|---|

| Drains | Auto drains cycling? Manual drains clear? | If blocked → clean/replace |

| Prefiltration | Coalescer ΔP/condition | If oil carryover → change elements, fix compressor |

| Dryer | Regeneration timing/heater/purge | If abnormal → service per OEM |

| Environment | Sudden ambient drop/line cold spots | Add insulation/heat trace as needed |

Q7: How do you verify accuracy?

A: Commission new meters in parallel with a known reference for 2–4 weeks; perform periodic handheld spot checks at the same tap to validate readings and locate dead legs.

Q8: How do you keep people aligned?

A: Document who watches, who acts, and how:

| Role | Responsibility | Tooling/Access |

|---|---|---|

| Operations | Daily trend review, acknowledge alarms | HMI/SCADA, alarm dashboard |

| Maintenance | Executes checklist & repairs | Work orders, spare probes/elements |

| Quality/EHS | Audits logs, verifies conformance (ISO 8573) | Reports, calibration certs |

How Do Dew Point Meters Work?

Q1: Which sensor principles should you consider?

A: Choose by required accuracy, response, and contamination tolerance.

| Sensor Type | Principle (What It Senses) | Best Use Case | Typical Accuracy |

|---|---|---|---|

| Chilled mirror | Mirror cooled until condensation appears | Reference labs, calibration standards | ±0.1 °C dp |

| Capacitif | Dielectric change with absorbed moisture | Fast inline plant monitoring | ±1–2 °C dp |

| Aluminum oxide | Conductivity change as moisture adsorbs | Budget monitoring, non-critical utilities | ±2–3 °C dp |

Q2: How do you protect sensors from fouling?

A: Oil aerosols, particulates, and corrosives shorten life. Use coalescing prefilters, particulate screenset sample conditioning (heated lines or bypass chambers) in wet/dirty streams.

Q3: What outputs and protocols matter for control and diagnostics?

A:

- 4–20 mA: rock-solid for PLC control and alarms.

- Modbus RTU: multi-parameter telemetry (dew point, temperature, probe status, sensor health).

Q4: How do you plan calibration and validation?

A: Schedule per sensor type and cleanliness; log offsets from parallel checks and keep certs with your quality records.

| Activity | Interval (Typical) | Notes |

|---|---|---|

| Inline spot-check | Quarterly | Handheld at same tap |

| Full calibration | 6–12 months | Traceable standard, more frequent in oily lines |

| After upset/repair | Event-based | Re-verify after dryer service or major excursion |

Q5: Where does HENGKO HG970 fit?

A: HG970 combines a robust sensing module with 4–20 mA and Modbus RTU, onboard logginget health metrics. Modular probe heads simplify swap-outs to minimize downtime.

Key Features and How to Specify Them

Q1: What ranges/accuracy do you actually need?

| Dryer Type | Recommended Measurement Range | Minimum Accuracy to Specify |

|---|---|---|

| Refrigerated | +10 … -5 °C dp | ±1–2 °C dp |

| Desiccant (-40 class) | 0 … -60 °C dp | ±2 °C dp |

| Desiccant (-70 class) | -20 … -80 °C dp | ±2 °C dp or better |

Q2: Which features reduce lifecycle cost (not just CapEx)?

| Fonctionnalité | Why It Matters | What to Ask the Vendor For |

|---|---|---|

| Dual output (4–20 mA + Modbus) | Control and rich diagnostics | Register map, scaling, status bits |

| Onboard logging | Root-cause analysis, audit trail | Download format, capacity, interval options |

| Replaceable sensor heads | Fast maintenance, less downtime | Hot-swap design, spare availability |

| IP-rated enclosure | Survives dust/oil/washdown | IP65/67 ratings, cable glands |

| Alarm logic on-probe | Local failsafe if PLC/HMI down | Setpoints, hysteresis, delay |

Q3: How do you turn requirements into a procurement checklist?

| Item | Your Minimum | Stretch/Ideal | Notes |

|---|---|---|---|

| Measurement range | ___ | ___ | Match dryer class |

| Accuracy & traceability | ___ | ___ | ISO-traceable certs required? |

| Outputs | 4–20 mA | + Modbus RTU | HMI trending + PLC alarms |

| Logging | 30–90 days | 180+ days | CSV/JSON export |

| Enclosure | IP65 | IP67 | Ambient/condensing conditions |

| Serviceability | Replaceable head | Hot-swap | Spare kits stocked |

| Calibration plan | 12 mo | 6–12 mo | Depends on air cleanliness |

HG970 fit: Modular heads, diagnostics, modern I/O, and logging—designed to hit the “Stretch/Ideal” column for many plants.

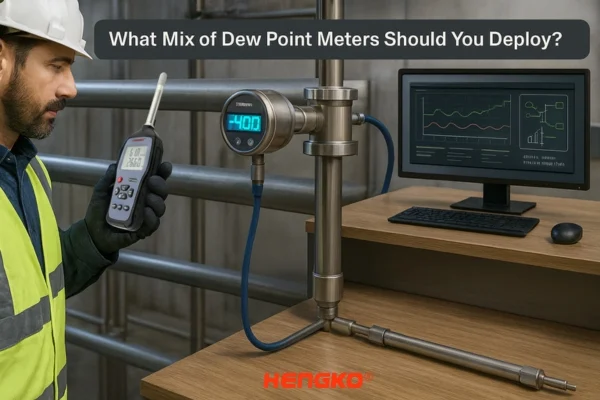

What Mix of Meters Should You Deploy?

Q1: Handheld vs. inline vs. networked—how do you choose?

| Option | Strengths | Limits | Best Use |

|---|---|---|---|

| Handheld meter | Low CapEx, flexible, great for audits | Labor-intensive, snapshot only | Commissioning, troubleshooting, spot-checks |

| Inline transducer | Continuous data, closes control loop | Per-point cost | Critical lines, dryer outlet, cold zones |

| Networked system | Plant-wide view, trends, centralized alarms | Integration effort | Multi-point analysis, quality & energy mgmt |

Q2: How do you protect and install probes for reliability?

| Condition | Protection/Method | Mounting Tip |

|---|---|---|

| Oily/dirty air | Coalescing prefilter + particulate screen | Install upstream and add ΔP gauge |

| Wet/condensing sample | Heated line or bypass chamber | Keep flow constant; avoid low points |

| Critical uptime | Dual redundant probes with 3-valve manifold | Enables swap without process shutdown |

Q3: What’s a simple commissioning plan that works?

| Week | Task | Output |

|---|---|---|

| 0 | Parallel run with reference | Offset baseline |

| 1 | Verify alarm thresholds/hysteresis/delay | Stable alarm behavior |

| 2 | Review trends; adjust placement if spikes persist | Optimized tap location |

| 4 | Lock response checklist; train operators | SOP + trained crew |

Q4: How do you think about total cost (TCO), not just price?

| Cost Component | Handheld-only | Inline (per point) | Networked (per site) |

|---|---|---|---|

| Instrument & accessories | $ | $$ | $$$ |

| Calibration & spares | $ | $$ | $$ |

| Labor (audits/response) | $$ | $ | $ |

| Downtime avoided (benefit) | - | $$ | $$$ |

| Energy saved via right-drying | - | $–$$ | $$–$$$ |

Rule of thumb: if moisture excursions cost more than one probe per year, inline monitoring pays for itself.

Q5: How do you integrate HG970 with PLC/SCADA fast?

| Signal/Map | Example (HG970) | Use in Control |

|---|---|---|

| 4–20 mA (dew point) | 4 mA = -80 °C, 20 mA = +20 °C | Analog alarm, dryer PID/feed-forward |

| Modbus holding reg. | 40001 = dew point (0.1 °C) | Precise trending, reports |

| Modbus status bits | Probe OK, sensor health | Maintenance alerts, bad-data suppression |

| On-probe alarms | SP1 = -35 °C, 90 s delay | Local interlock if PLC offline |

Conclusion

You prevent condensation, protect equipment, and save energy when you select, place, and integrate dew point meters correctly. The HENGKO HG970 series offers the accuracy, connectivity, logging, and diagnostics you need for reliable plant monitoring—without over-drying or surprise moisture events.