Bevezetés

Have you ever wondered how to measure the moisture in your compressed air accurately? The harmatpont plays a crucial role in understanding and controlling moisture levels in compressed air systems. It’s the temperature at which air becomes saturated and moisture begins to condense, potentially causing damage to your equipment and processes.

In this article, we’ll provide you with practical tips and guidance on how to calculate and measure the dew point effectively, ensuring your systems stay dry and reliable. Let’s dive in!

Mi a harmatpont?

The dew point is the temperature at which the air becomes saturated with water vapor and condensation begins to form. It’s like the “sweet spot” where water vapor in the air turns into liquid water, forming dew, fog, or clouds. The higher the dew point, the more moisture is in the air.

Have you ever noticed how your glasses fog up when you go from a cold to a warm place? This happens because the warm air in the room can hold more water vapor than the cold air outside. When your glasses cool down, the water vapor in the air condenses on them, forming fog. This is a great example of how dew point works in everyday life.

The Importance of Dew Point In Compressed Air Systems

The dew point is a pivotal temperature threshold in compressed air systems, marking the transition from vapor to liquid state for moisture in the air. Understanding and controlling the dew point is essential for several reasons:

-Preventing Condensation: By keeping the compressed air above its dew point, condensation and the associated formation of water can be avoided, preventing potential damage and inefficiencies.

-System Integrity: Excess moisture can lead to corrosion and other forms of damage within the system, undermining its integrity and lifespan.

-Efficiency: Compressed air systems operate most efficiently when free of condensation. Managing the dew point ensures that the air remains in a gaseous state, optimizing performance.

-Safety: Uncontrolled moisture can lead to hazardous conditions, especially in sensitive applications like food processing or electronics manufacturing.

-Energy Savings: Properly managing the dew point can reduce the energy required to dry the air, leading to significant energy savings.

What is humidity

Humidity refers to the quantity of water vapor in the air, which can impact comfort, health, and industrial processes. It is typically expressed in one of the following ways:

*Relative Humidity: The percentage of the current absolute humidity compared to the maximum absolute humidity at the same temperature. It gives an indication of how close the air is to being saturated with water vapor.

*Absolute Humidity: The actual amount of water vapor present in a given volume of air, usually measured in grams per cubic meter (g/m³).

*Specific Humidity: The amount of water vapor per unit mass of dry air, often measured in grams per kilogram (g/kg).

Factors Affecting Dew Point in Compressed Air

●Temperature: The primary factor affecting the dew point is the temperature of the compressed air. As the temperature decreases, the air’s capacity to hold water vapor decreases, leading to a lower dew point.

●Nyomás: The dew point changes with pressure. As pressure increases, the air can hold more moisture, and the dew point will shift accordingly.

●Compression: Compressed air often holds more moisture because the air is cooled rapidly during compression, forcing moisture to condense inside the system.

●Humidity: The amount of moisture in the air affects the dew point. Higher humidity means the air is closer to saturation, and thus the dew point will be higher.

Relationship Between Humidity and Dew Point in Compressed Air Systems

In a compressed air system, humidity and dew point are closely related. Humidity is the amount of water vapor in the air, while dew point is the temperature at which the air can no longer hold all of its water vapor and some of it condenses into liquid water.

As the air in a compressed air system is compressed, its temperature increases. This can cause the relative humidity to decrease, even though the absolute amount of water vapor in the air remains the same. However, the dew point also increases with compression.

If the compressed air is cooled to its dew point, the water vapor will condense into liquid water. This can cause problems in the compressed air system, such as:

-Reduced efficiency of the system

-Corrosion of the system components

-Contamination of the compressed air

-Damage to equipment that uses the compressed air

To avoid these problems, it is important to keep the dew point of the compressed air below the lowest temperature that the air will be exposed to in the system. This can be done by using a desiccant air dryer or a refrigerated air dryer.

How to Measure the Dew Point of Compressed Air

1.Using a Dew Point Formula

You can calculate the dew point using a mathematical formula based on the temperature and relative humidity. One commonly used formula is the Magnus-Tetens approximation, which provides an estimate for the dew point temperature.

Formula: b·α (T,RH) ÷ 2a-α

· Td = Dew point temperature (°C)

· T = Air temperature (°C)

· RH = Relative humidity (%)

· a=17.27

· b=237.7

· α (T,RH)= (a·T)÷(b+T) + ln(RH/100)

This formula can be used if you have the air temperature and relative humidity.

Here’s how to apply it:

-Measure the air temperature (T) and relative humidity (RH).

-Plug these values into the formula.

-Calculate the dew point (T_d) using the equation.

2. Using a Harmatpont mérő

The easiest and most accurate way to measure the dew point of compressed air is to use a dew point meter or hygrometer. These devices are designed to directly measure the dew point by determining the temperature at which condensation occurs.

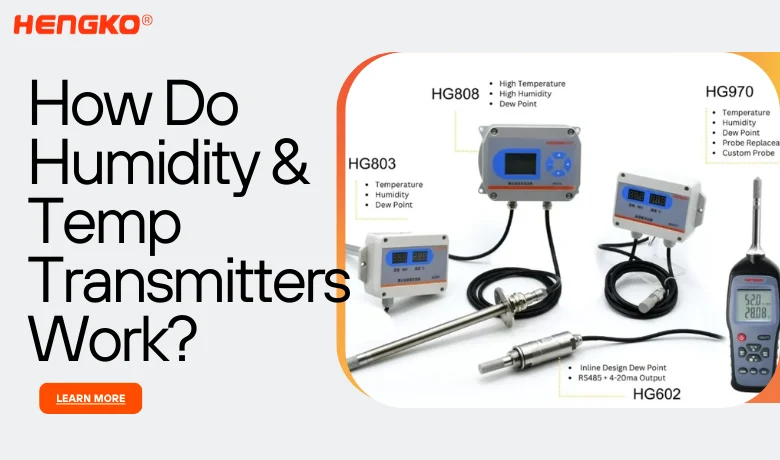

For your compressed air system, HVAC and air dryer system, HENGKO offers a comprehensive range of dew point monitoring solutions to meet your specific needs. Our product includes:

-HG970 Handheld Dew Point Meter: Compact, portable, and designed for on-the-go applications, this device features advanced sensor technology to deliver accurate and precise dew point readings, making it ideal for field use.

-HG602 Online/Inline Dew Point Sensor: Designed for continuous monitoring, this sensor can be integrated into your existing systems to provide real-time dew point data, ensuring optimal performance and efficiency.

-HG808 Dew Point Transmitter: Ideal for fixed installations, this transmitter offers a reliable and stable way to monitor dew point levels in your facility, with easy-to-read displays and advanced features for data management.

HENGKO provides precise moisture control with our advanced dew point measurement instruments. Besides, our expert engineers are here to provide tailored solutions for your dew point monitoring needs. Contact us at sales@hengkometer.com today to find the perfect system for your application and optimize your operations!

3. Using a Psychrometric Chart

Another method to calculate the dew point is using a psychrometric chart, which plots the relationship between temperature, relative humidity, and dew point. Here’s how you can use it:

Steps:

①Measure the air temperature and relative humidity of the compressed air.

②Plot the measured values on the psychrometric chart (temperature on the x-axis, relative humidity on the y-axis).

③Find the intersection point of the temperature and relative humidity on the chart.

④Trace horizontally to the dew point line, which will give you the corresponding dew point temperature.

This method requires more manual effort, but it can still be very useful if a dew point meter is not available.

Következtetés

In summary, managing the dew point in compressed air systems is crucial to prevent moisture-related issues like corrosion and contamination. By using accurate measurement tools, such as dew point transmitters, and understanding factors like humidity, temperature, and system pressure, you can ensure optimal performance and efficiency. Proper dew point control helps maintain equipment reliability and product quality, making it an essential part of system maintenance and operation.

If you have dew point measurement needs or are interested in our products, feel free to browse our website for more insights or contact us at sales@hengkometer.com for professional consultation and customized solutions. Our team is ready to help you choose the perfect equipment and provide expert guidance to optimize your system’s performance.