Dew Point Sensor for Air Dryer

고급 이슬점 모니터링으로 공기 시스템 최적화

홈 " Dew Point Sensor for Air Dryer

Dew Point Sensor for Industrial Compressed Air Dryer Solution Supplier

Leading Provider of Dew Point Sensors for Industrial Compressed Air Dryer Solutions - HENGKO

HENGKO is one of professional supplier of dew point sensors for industrial compressed air dryer solutions. We supply kinds of temperatture humidity transmitter and sensor for widely used industrial humidity and temperature monitor.

- High Quality: Our sensors are built to last and perform reliably.

- Accurate Monitoring: Precise measurement of moisture levels to keep your systems in check.

- Prevent Damage: Helps to avoid system failures and costly repairs.

- Efficient Performance: Ensures optimal performance of your industrial applications.

- 다양한 애플리케이션: Suitable for a wide range of industrial uses for compressed air dryer system.

온라인 산업용 노점 측정 - HG602

주요 기능

HG602는 정밀도와 신뢰성을 위해 설계되어 효율적인 압축 공기 시스템 관리를 위한 필수 노점 측정 기능을 제공합니다.

- 측정 범위50°C ~ +20°C로 다양한 작동 조건에 적합합니다.

- 압력 기능: 최대 35MPa(350bar)의 고압 구성 옵션으로 -0.1 ~ 5.0MPa의 압력을 처리할 수 있습니다.

- 출력 및 커뮤니케이션: 기존 제어 시스템과 원활하게 통합할 수 있도록 4-20mA 및 HENGKO 디지털 출력을 모두 제공합니다.

- 전원 공급 장치: 12-30Vdc, 60mA로 효율적으로 작동합니다.

- 설치 유연성: G1/2인치 수나사 및 IP65 등급의 컴팩트한 디자인으로 쉽고 안전하게 설치할 수 있습니다.

- 향상된 센서 기술: 새로 개발된 센서가 탑재되어 신호 안정성이 향상되고 -50°C까지 장기간 안정적으로 사용할 수 있습니다.

- 다양한 피팅 옵션: 다양한 측정 챔버와 호환 가능하여 푸시핏 또는 고속 커넥터를 사용하여 모든 배관 체계에 유연하게 통합할 수 있습니다.

Online Dew Point Transmitter Series

Wall Mounted Dew Point Transmitter Series

휴대용 산업용 이슬점 측정기

- HG970 시리즈

주요 기능

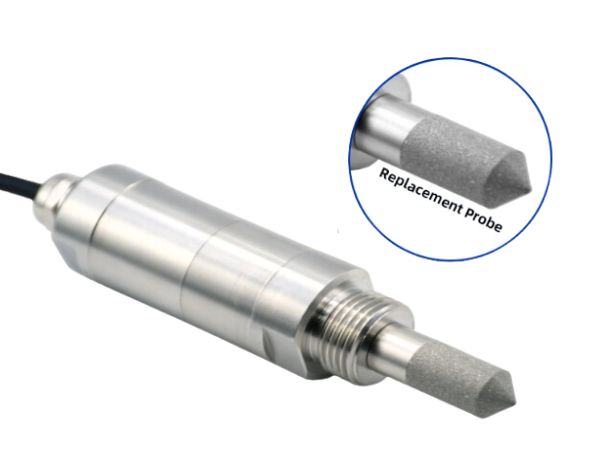

HG970은 산업 환경에서 탁월한 성능을 발휘하도록 설계되었으며 내구성이 뛰어나고 교체 가능한 금속 프로브 디자인으로 수명이 길고 설치가 간편합니다.

이 휴대용 측정기는 신속하고 정확한 수분 감지를 위한 센서 퍼지 기능으로 응답 시간이 크게 향상되어 데이터를 빠르고 정확하게 전달하도록 설계되었습니다.

까다로운 조건에서도 신뢰할 수 있는 측정:

HG970의 견고한 센서는 결로 현상을 견디고 습기에 노출된 후에도 완전히 복구되어 까다로운 조건에서도 신뢰할 수 있는 판독값을 제공합니다.

향상된 사용성을 위한 직관적인 사용자 인터페이스:

HG970에는 사용하기 쉬운 그래픽 LCD 디스플레이가 장착되어 있어 데이터를 명확하게 시각화할 수 있습니다. 직관적인 인터페이스와 광범위한 데이터 로깅 기능이 결합되어 있어 이동 중에도 종합적인 수분 분석을 위한 이상적인 도구입니다.

HG970meter는 다양한 산업 환경에서 빠르고 정확한 이슬점 측정과 신뢰할 수 있는 성능을 필요로 하는 전문가에게 적합합니다.

Why It is so import to Monitor Dew-Point in Air Dryer System?

Monitoring the dew point in an air dryer system is crucial for several reasons:

Prevents Corrosion and Equipment Damage: Water vapor in compressed air can condense into liquid water when temperatures drop below the dew point. This moisture can lead to rust and corrosion within pipes, tanks, and other equipment. This can significantly weaken the system and lead to expensive repairs or replacements.

Ensures Optimal Performance of Equipment: Many pneumatic tools and machinery rely on clean, dry air to function correctly. Moisture can cause malfunctions, reduced efficiency, and even complete failure.

Maintains Product Quality: In processes like spray painting, moisture in the compressed air can cause imperfections or defects in the final product.

Optimizes Dryer Performance: Regular dew point monitoring allows you to ensure your air dryer is functioning properly and removing moisture to the desired level. This can help identify potential problems with the dryer early on and prevent costly repairs.

Extends Maintenance Intervals: By keeping the dew point under control, you can lessen wear and tear on your equipment, leading to extended maintenance intervals and lower overall costs.

In short, monitoring dew point is essential for protecting your equipment, ensuring efficient operation, and maintaining product quality in compressed air systems.

What Factor You Should Care When Choose Dew Point Sensor for Your Air Dryer Device ?

Here are some key factors by our experience you should consider when choosing a dew point sensor for your air dryer device:

Accuracy and Reliability: This is arguably the most important factor. The sensor needs to consistently measure extremely low moisture levels to ensure your compressed air meets the required dryness specifications. Look for sensors with high accuracy ratings and a proven track record of reliability.

응답 시간: The sensor should be able to detect changes in dew point quickly. This is particularly important for systems where moisture content can fluctuate rapidly. A fast response time allows for prompt corrective action if the dew point rises above the desired level.

안정성: Over time, some sensors can drift, meaning their readings become less accurate. Choose a sensor with good long-term stability that minimizes drift and requires minimal recalibration.

Contaminant Resistance: Compressed air can contain oil vapors and particulates. The sensor should be resistant to these contaminants to ensure accurate readings and avoid malfunction. Some sensors may require filters to protect them from contamination.

Ease of Maintenance and Calibration: Regular maintenance and calibration are essential for any dew point sensor. Consider how easy it is to access the sensor for maintenance and how often calibration is required.

Operating Environment: Consider the temperature and pressure range the sensor will be operating in. Make sure the sensor is rated for the conditions within your air dryer system.

Consulting with a compressed air system specialist can be helpful in choosing the right dew point sensor for your specific application. They can help you assess your needs and recommend sensors that meet your requirements.

적합한 온도 및 습도 트랜스미터 찾기

오늘 프로젝트를 알려주세요

모니터 프로젝트 세부 정보를 알려주세요,

3일 이내에 경쟁력 있는 가격으로 최고의 솔루션을 제공해 드립니다.

3일 이내에 경쟁력 있는 가격으로 최고의 솔루션을 제공해 드립니다.

전 세계로 퍼뜨리기

HENGKO는 독특한 디자인과 뛰어난 성능으로 명성이 높은 산업용 센서 솔루션 분야의 글로벌 리더입니다. 당사의 온도 및 습도 트랜스미터와 센서는 식음료, 제약, 제조, 환경 모니터링 등 다양한 산업 분야에서 사용되고 있습니다.

0

+

수년간의 경험

0

전 세계 판매

0

K