습도 및 온도 트랜스미터는 어떻게 작동하나요?

간단히 말해, 습도 및 온도 트랜스미터는 환경 데이터를 측정하여 제어 시스템으로 전송합니다. HVAC, 제약, 식품 가공 및 클린룸에서 널리 사용됩니다.

항목 번호: HG808-G series

그리고 HG808-G is an industrial-grade dew point and temperature transmitter specifically engineered for corrosive or chemically aggressive environments. Built with a 316L stainless steel sintered probe and a sealed aluminum housing, it ensures stable and accurate measurement even in the presence of acidic gases, solvents, salt spray, or oil mist.

In addition to measuring and transmitting dew point and temperature, the HG808-G can calculate and output relative humidity and PPM values, providing a comprehensive view of ambient moisture conditions for process control and quality assurance.

다음은 주요 기능에 대한 분석입니다:

Corrosion-Resistant Design: 316L stainless steel probe with nano-coated anti-corrosion finish, suitable for acidic, alkaline, and solvent vapors.

높은 정확도: ±3 °C Td dew point accuracy across a range of –80 °C to +60 °

Wide Power & Pressure Range: Operates on DC 12 – 24 V, withstands up to 10 bar pressure.

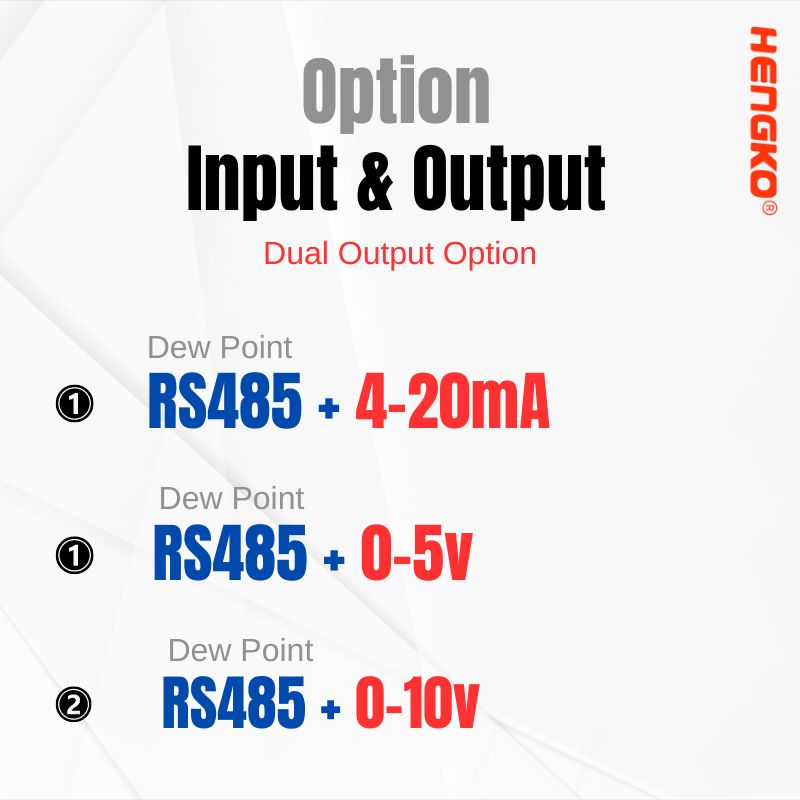

Flexible Output Options:

RS485 (Modbus-RTU) digital output

4-20mA 아날로그 출력

Optional 0-5 V / 0-10 V analog outputs

Industrial Protection: IP65-rated enclosure, anti-condensation heating, and strong EMI resistance for reliable long-term use.

Integration-Ready: Easily connects to PLCs, DCS, or SCADA systems for automated dew point monitoring and process control.

▪Engineered for Harsh Chemical Environments

Built with 316L stainless steel and anti-corrosion coating to withstand acids, alkalis, solvents, and salt mist. Ideal for chemical, pharmaceutical, and lithium-battery industries.

▪High Accuracy Dew Point Monitoring

Provides ±3 °C Td accuracy over a wide range (–80 °C to +60 °C), ensuring precise control in ultra-dry or low-humidity processes.

▪Comprehensive Measurement Capability

Simultaneously measures and outputs dew point, temperature, humidity, and PPM values, giving a full picture of environmental moisture conditions.

▪Flexible Output Options

Supports RS485 (Modbus-RTU) digital communication, plus 4–20 mA, 0–5 V, and 0–10 V analog signals for easy integration with PLC, DCS, and SCADA systems.

▪Industrial-Grade Reliability

IP65 aluminum housing with anti-condensation function, resistant to oil, dust, and high humidity for stable long-term operation under 10 bar pressure.

▪Compact and Service-Friendly Design

Modular structure with replaceable sintered probe, simplifying installation and reducing maintenance time and cost.

▪Wide Power Supply Range

Operates on 12–24 V DC with reverse-polarity and surge protection for reliable use in demanding industrial environments.

Here’s a specification details for the HG808-G series Humidity Transmitter :

| 카테고리 | 사양 |

|---|---|

| Measurement Parameters | Dew Point, Temperature, Humidity, PPM (for reference) |

| 이슬점 범위 | –60 °C ~ +20 °C |

| Dew Point Accuracy | ±3 °C Td (±5.4 °F) |

| 온도 범위 | –20 °C ~ +60 °C |

| 온도 정확도 | ±0.2 °C (@ 23 °C) |

| Temperature Long-Term Stability | ≤ 0.1 °C / year |

| Humidity Long-Term Stability | ≤ 1 % RH / year |

| Digital Output | RS485 (Modbus-RTU); outputs temperature, humidity, dew point, PPM (humidity & PPM for reference only) |

| 아날로그 출력 | Temperature + Dew Point – select one: 4-20 mA / 0-5 V / 0-10 V |

| Pressure Resistance | ≤ 16 bar |

| 전송 속도 | 1200, 2400, 4800, 9600, 19200, 115200 bps (selectable; default 9600 bps) |

| 수집 빈도 | Fastest response 1 second; adjustable via PLC |

| Working Environment | –20 °C ~ +60 °C; 0 % ~ 95 % RH (non-condensing) |

| 전원 공급 장치 | DC 12 V ~ 24 V, reverse-polarity protected |

| 전력 소비량 | < 0.5 W |

| Output Protocol | Standard Modbus-RTU; compatible with PLC, DCS, and SCADA systems |

| Construction | Compact aluminum housing with industrial grade ESD & anti-reverse protection |

| Installation & Customization | Custom probe design available according to application needs (structure, shape, length, material, mounting method) |

| Protection Rating | IP65 – dustproof and moisture-resistant |

| Applicable Probe Options | Two probe types available: • Gas Sampling Unit • 316L Stainless Steel Sintered Protective Housing (A-Type, 0A# / 8A#) |

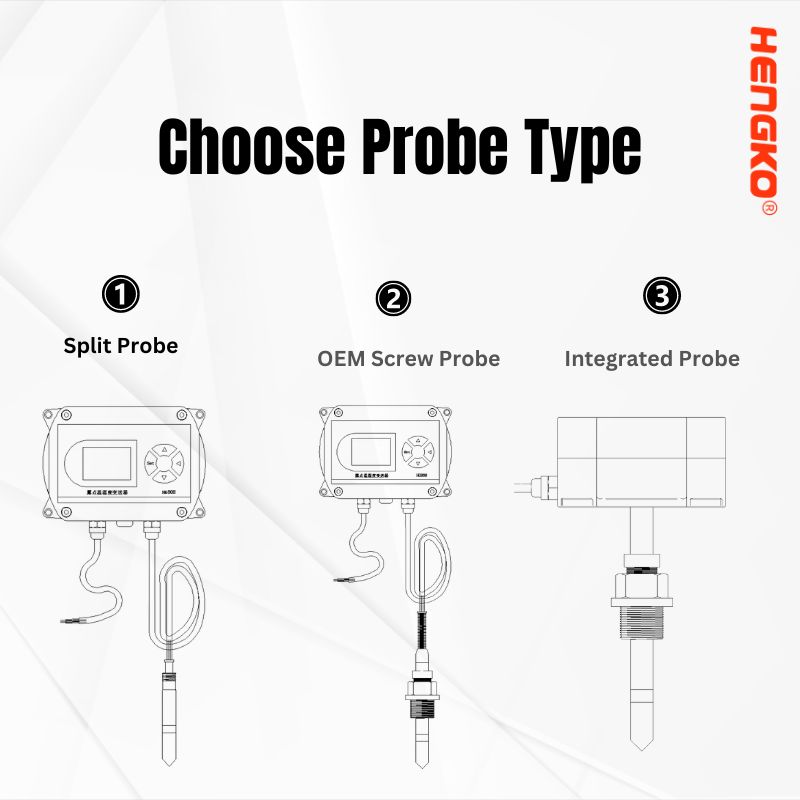

HG808 습도 트랜스미터에는 6가지 유형의 프로브가 제공되며, 각 유형은 A 및 B 버전으로 제공되어 다양한 애플리케이션 옵션에 맞게 총 12개의 프로브를 사용할 수 있습니다.

0A#

8A#

M20 육각 나사산 스테인리스 스틸 프로브 커넥터

G1/2 육각 나사산 스테인리스 스틸 프로브 커넥터

NTP1/2 육각 나사산 스테인리스 스틸 프로브 커넥터

M27 육각 나사산 스테인리스 스틸 프로브 커넥터

M20 플랜지 스테인리스 스틸 프로브 커넥터

| 선 색상 | 정의 | 사양 |

|---|---|---|

| 전원 코드 | ||

| 빨간색 | 전원 공급 장치 양성 | 10 ~ 30V DC |

| 블랙 | 전원 공급 장치 음극 | GND |

| 아날로그 출력 라인 | ||

| 브라운 | 온도 신호 양성 | 4-20mA 출력 |

| 파란색 | 온도 신호 음수 | 검정색(GND)에 연결 |

| 회색 | 습도 신호 양성 | 4-20mA 출력 |

| 흰색 | 습도 신호 음수 | 검정색(GND)에 연결 |

| RS485 배선 | ||

| 노란색 | RS485A | 트위스트 페어 케이블 |

| 녹색 | RS485B | 트위스트 페어 케이블 |

추가 참고 사항:

중요:

Precise dew point and humidity monitoring is critical to prevent moisture contamination of electrolyte solutions 그리고 ensure uniform electrode coating quality.

Typical conditions: Dew point ≤ –40 °C, temperature 20 – 30 °C, humidity < 1 % RH.

Control requirement: Continuous online dew point monitoring in glove boxes and drying chambers for ultra-low humidity environments.

During chemical synthesis or solvent recovery, excessive moisture can affect reaction yield, purity, and safety. The HG808-G provides stable measurements even in acidic, solvent, or oil-vapor atmospheres.

Typical conditions: Dew point –40 ~ 0 °C, temperature 25 – 60 °C, humidity 5 – 40 % RH.

Control requirement: Corrosion-resistant dew point monitoring under HF, HCl, NH₃, or VOC exposure to prevent condensation and corrosion.

Humidity and temperature stability are essential to maintain API potency and drying uniformity. The HG808-G ensures accurate dew point and temperature control in cleanrooms and drying ovens.

Typical conditions: Dew point –30 ~ +10 °C, temperature 40 – 80 °C, humidity 2 – 20 % RH.

Control requirement: Real-time humidity feedback to optimize drying cycles and ensure GMP-compliant environmental monitoring.

FGD processes involve high-temperature, corrosive gases with varying moisture content. The HG808-G’s 316L stainless-steel probe withstands SO₂/SO₃ and acid mist for long-term reliability.

Typical conditions: Temperature 60 – 120 °C, humidity 10 – 80 % RH, dew point 0 ~ 50 °C.

Control requirement: Dew point monitoring for condensation control and corrosion prevention in gas treatment systems.

Stable dew point monitoring is required to prevent pipeline condensation, corrosion, and particulate accumulation in emission control systems.

Typical conditions: Temperature 30 – 90 °C, dew point –20 ~ 40 °C, humidity 5 – 70 % RH.

Control requirement: Continuous dew point trend tracking to maintain safe moisture levels before gas filtration or catalytic processing.

The HG808-G is engineered with an integrated corrosion-resistant structure, using 316L stainless steel and a sealed cast-aluminum housing (IP65). It resists acids, alkalis, electrolyte vapors, and chemical solvents, making it ideal for lithium battery, chemical, and pharmaceutical applications where standard sensors fail.

This transmitter has undergone strict testing for oil-gas mixtures, chemical corrosion, and dust impact. Its IP65-rated aluminum enclosure 그리고 pressure-resistant 316L probe can withstand up to 16 바, ensuring long-term stability and reliability even in challenging process environments.

The HG808-G offers flexible signal outputs for easy system integration:

Digital: RS485 (Modbus-RTU) for dew point, temperature, humidity, and PPM values.

Analog: Dual-channel outputs of 4-20 mA, 0-5 V, or 0-10 V (user selectable).

This design allows seamless connectivity with PLC, DCS, or SCADA systems for automated dew point and temperature control.

Yes. The transmitter includes data-recording functionality and supports connection to backend analysis software. Users can generate reports and trend charts with one click, enabling efficient monitoring, traceability, and process optimization.

The HG808-G can output dew point temperature, process temperature, relative humidity, and PPM values at the same time—providing a complete picture of gas dryness and system conditions.

By integrating advanced sensor technology and optimized circuitry, the HG808-G matches the performance of imported brands at a significantly lower cost. It delivers high precision, strong corrosion resistance, and excellent long-term stability, helping customers reduce maintenance and procurement costs.

Yes. HENGKO offers customized probe designs (structure, length, material, and mounting method) to meet specific process requirements—ensuring accurate and stable dew point measurement under any industrial condition.

간단히 말해, 습도 및 온도 트랜스미터는 환경 데이터를 측정하여 제어 시스템으로 전송합니다. HVAC, 제약, 식품 가공 및 클린룸에서 널리 사용됩니다.

건조기 노점 측정기가 압축 공기 시스템에 중요한 이유는 무엇일까요? 부식과 동결을 유발할 수 있는 압축 공기의 숨겨진 수분과 항상 싸우고 있을지도 모릅니다,

한 사무실 구역이 너무 습한 이유 및 습도 트랜스미터로 해결하는 방법 한 사무실 구역의 지속적인 습도는 쾌적함을 방해하고 곰팡이를 증가시킬 수 있습니다.

소개 압축 공기는 현대 산업에서 전기, 수도, 가스와 함께 '제4의 유틸리티'로 불리기도 합니다. 하지만 가장 일반적인

1. 서론 반도체 산업은 모든 제조 분야 중 가장 엄격한 환경 조건에서 운영됩니다. 디바이스가 나노 규모로 축소되고

소개 환경 시뮬레이션 및 신뢰성 테스트 분야에서 항온항습 챔버는 전자 제품부터 다양한 산업 분야에 걸쳐 필수적인 도구입니다.

WhatsApp 문의하기