Why Monitor Natural Gas Dew Point?

In Short, While natural gas is a valuable resource, monitoring its dew point before use is essential. Accurate dew point measurement is crucial to ensure the safe and efficient operation of machinery and devices that rely on natural gas.

Then Let’s Check Why we have to Monitor the Dew Point for the Natural Gas, first it is very important, let we expain reasons.

The Importance of Natural Gas

Natural gas is a versatile fuel source used for:

*Power generation

*Heating homes and buildings

*Industrial processes

*Transportation (CNG)

Notes: Natural gas plays a vital role in our global energy mix. It is used to generate electricity, heat homes and buildings, power industrial processes, and fuel vehicles in the form of compressed natural gas (CNG).

Why Monitor Natural Gas Dew Point?

The dew point of natural gas refers to the temperature at which water vapor present in the gas condenses into liquid water. This is crucial because liquid water can cause several problems in pipelines, machinery, and equipment that use natural gas:

* Maintaining Operational Efficiency: By keeping water vapor within specified limits, you prevent issues like hydrate formation that can obstruct pipelines and halt operations.

* Ensuring Safety: Monitoring dew point helps prevent condensation and freezing in pipelines, which could lead to dangerous blockages and equipment damage.

* Optimizing Costs: Controlling dew point reduces expenses associated with gas transportation and compression. It also helps avoid unplanned shutdowns that can be costly.

* Preserving Equipment: Managing moisture levels extends the lifespan of pneumatic components and other machinery that might be susceptible to water damage.

* Mitigating Corrosion: Monitoring dew point helps prevent the formation of acids that can corrode pipelines and equipment due to reactions between water and gases like H2S and CO2.

This list effectively communicates the importance of dew point monitoring for a safe, efficient, and cost-effective natural gas operation.

Monitoring Methods for Natural Gas Dew Point

Several methods are used to monitor the dew point of natural gas, each with its advantages and limitations:

- Chilled mirror hygrometers: This traditional method uses a mirror cooled until water vapor condenses on its surface. The temperature at which condensation occurs is the dew point. However, it requires skilled operators and can be time-consuming.

- Electrical impedance sensors: These sensors measure changes in electrical properties caused by moisture absorption, providing a continuous dew point reading. They are compact and reliable but may require regular calibration.

- Tunable diode laser absorption spectroscopy (TDLAS): This advanced method uses lasers to measure specific water vapor concentrations, offering high accuracy and real-time monitoring. However, TDLAS systems can be more expensive than other options.

So, The choice of monitoring method depends on various factors like required accuracy, frequency of measurement, cost, and operational environment.

Technological Solutions for Dew Point Detection

Ensuring optimal natural gas quality requires precise monitoring of its dew point. Traditional methods, while valuable, can be time-consuming or limited in accuracy. Thankfully, advancements in technology offer a range of high-tech tools for dew point detection in natural gas.

Advanced Tools and Technologies:

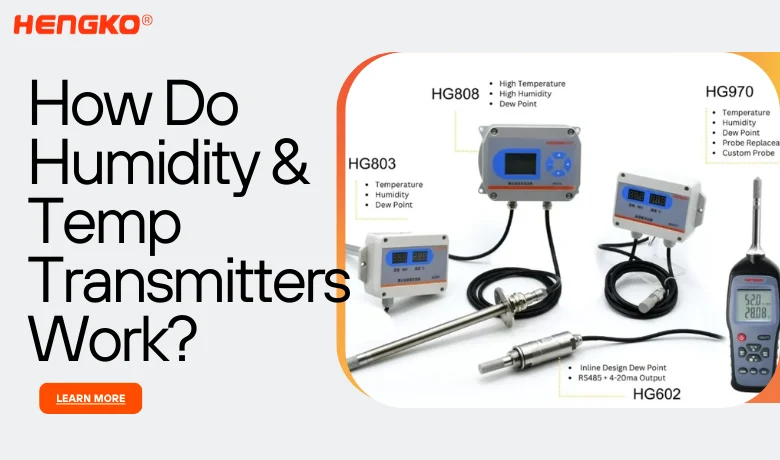

- HENGKO Transmitter för temperatur och luftfuktighet Data Logger Module: This is just one example of a sophisticated dew point detection system. It combines a high-accuracy temperature sensor with a humidity sensor, allowing for real-time dew point calculations. Data loggers like this one can:

- Record and store data: Continuously monitor and store dew point readings over time, providing valuable insights into trends and fluctuations.

- Set alarms: Program alarms to trigger when dew point levels deviate from the desired range, enabling proactive maintenance and preventing potential issues.

- Remote monitoring: Access dew point data remotely for centralized monitoring and analysis, improving operational efficiency.

- HENGKO supply wide Dew Point Monitor Solution, You can Choose Inline Dew Point Transmitter, Handheld Dew Point Meter, Wall Mount Dew Point Transmitter, High Temperature Dew Point Transmitter etc

- Chilled Mirror Hygrometers: This established technique utilizes a mirrored surface that cools progressively until condensation forms. The temperature at which condensation occurs reflects the dew point. However, these instruments require skilled personnel and can be time-consuming to operate.

- Electrical Impedance Sensors: These compact sensors measure changes in electrical properties caused by moisture absorption, providing a continuous dew point reading. They are a reliable option but require periodic calibration to ensure accuracy.

- Tunable Diode Laser Absorption Spectroscopy (TDLAS): This cutting-edge method utilizes lasers to precisely measure specific water vapor concentrations. TDLAS offers exceptional accuracy and real-time monitoring capabilities, but comes at a higher cost compared to other options.

Benefits of High-Accuracy Sensors and Data Loggers:

- Improved Decision-Making: Real-time and accurate dew point data empowers informed decisions regarding pipeline maintenance, dehydration processes, and overall operational adjustments.

- Enhanced Safety: Early detection of potential dew point issues helps prevent hydrate formation, corrosion, and other safety hazards associated with condensation.

- Optimized Costs: Precise dew point data allows for targeted dehydration efforts, minimizing energy consumption and reducing unnecessary treatment.

- Reduced Downtime: Proactive maintenance based on accurate dew point monitoring helps prevent equipment failures and unplanned shutdowns.

- Streamlined Operations: Data loggers automate dew point recording and analysis, minimizing manual intervention and streamlining operations.

By incorporating these advanced tools and technologies, the natural gas industry can achieve superior dew point detection, leading to safer, more efficient, and cost-effective operations.

Applications of Dew Point Measurement in Industry

Dew point measurement transcends the natural gas industry, playing a vital role in ensuring operational reliability and safety across a wide range of industrial and commercial applications. Here’s a glimpse into some key sectors where dew point monitoring is crucial:

1. Compressed Air Systems:

Dew point control is paramount in compressed air systems used in manufacturing and various facilities. Excess moisture can lead to:

- Korrosion: Damaged pipelines and equipment due to rust formation.

- Contamination: Reduced product quality from moisture-induced defects or compromised performance of pneumatic tools.

- Equipment Failure: Freeze-ups caused by condensation within air lines.

By monitoring dew point, industries can maintain dry air, preventing these issues and ensuring smooth operation.

2. Pharmaceutical and Food Production:

Precise dew point control is essential in these sectors to:

- Maintain Product Quality: Moisture can impact the stability, effectiveness, and shelf life of pharmaceuticals and food products.

- Prevent Microbiological Growth: High moisture levels create a breeding ground for harmful bacteria and mold.

- Optimize Drying Processes: Dew point monitoring helps determine optimal drying conditions for products, improving efficiency and energy usage.

3. Chemical Processing:

Dew point control plays a crucial role in chemical processes by:

- Preventing unwanted reactions: Moisture can trigger undesirable reactions between chemicals, impacting product quality and safety.

- Ensuring Product Consistency: Consistent dew point levels ensure consistent product characteristics.

- Maintaining Equipment Integrity: Moisture can damage sensitive equipment used in chemical processing.

4. Semiconductor Fabrication:

Semiconductor manufacturing demands extremely dry environments. Dew point monitoring helps:

- Minimize Defects: Moisture can cause malfunctions and defects in delicate circuits.

- Maintain Process Control: Consistent dew point levels ensure predictable and reliable chip production.

- Prevent Corrosion: Moisture can damage expensive semiconductor manufacturing equipment.

5. Storage and Transportation:

Dew point control is crucial for:

- Preserving Materials: Moisture can damage hygroscopic materials like wood, paper, and certain chemicals.

- Preventing Condensation: Managing dew point helps prevent condensation on stored products or within shipping containers.

- Ensuring Product Quality: Dew point control safeguards the integrity of stored and transported goods.

Slutsats

Monitoring the dew point in natural gas is indispensable for ensuring the effective and safe utilization of this vital energy resource. The dew point is a critical parameter that signifies the temperature at which water vapor in natural gas condenses into liquid. Proper management of this aspect prevents operational hazards such as pipeline blockages and equipment corrosion, and it safeguards against efficiency losses and potential safety risks due to condensation and freezing in the gas lines.

Discover Our Dew Point Monitoring Solutions – Ensure your natural gas applications meet the highest standards of safety and efficiency with our state-of-the-art monitoring tools.

With our advanced solutions at your fingertips, you can confidently manage your natural gas systems, guaranteeing optimal performance and safeguarding your valuable assets against unforeseen issues. Check out our offerings today and step into a safer, more efficient future.