Capteur de point de rosée pour l'air comprimé

Optimisez vos systèmes d'air grâce à la surveillance avancée du point de rosée

Accueil " Capteur de point de rosée pour l'air comprimé

Capteur de point de rosée pour l'air comprimé Fournisseur de solutions diverses

Diverses solutions de point de rosée pour une gestion complète du système d'air

HENGKO est à la pointe de l'innovation en tant que fournisseur de premier plan de capteurs de point de rosée pour systèmes d'air comprimé.

Nous proposons une gamme variée de solutions adaptées pour répondre à la norme internationale ISO 8573-1 relative à la qualité de l'air comprimé. L'air comprimé doit être séché et filtré pour éliminer l'excès d'humidité et les particules. Nos capteurs de point de rosée garantissent des performances et une fiabilité optimales dans la surveillance et la gestion des niveaux d'humidité de l'air, améliorant ainsi l'efficacité et la sécurité des opérations d'air comprimé dans diverses industries.

Faites confiance à HENGKO pour vous fournir des solutions de capteurs personnalisées et de qualité supérieure qui vous aideront à atteindre vos objectifs.

Mesure en ligne du point de rosée dans l'industrie - HG602

Caractéristiques principales

Le HG602 est conçu pour la précision et la fiabilité, fournissant des mesures essentielles du point de rosée pour une gestion efficace du système d'air comprimé.

- Plage de mesureLa température de fonctionnement est comprise entre -50°C et +20°C, ce qui est parfait pour les diverses conditions d'utilisation.

- Capacité de pression: Prend en charge des pressions de -0,1 à 5,0 MPa avec une configuration haute pression optionnelle jusqu'à 35 MPa (350 bar).

- Sortie et communication: Offre des sorties 4-20mA et des sorties numériques HENGKO pour une intégration transparente dans les systèmes de contrôle existants.

- Alimentation électrique: Fonctionnement efficace avec 12-30Vdc à 60mA.

- Flexibilité d'installation: Conception compacte avec filetage mâle G1/2″ et indice de protection IP65 pour une installation facile et sûre.

- Technologie de capteur améliorée: Capteur nouvellement développé pour une meilleure stabilité du signal et une fiabilité à long terme jusqu'à -50°C.

- Options de montage polyvalentes: Compatible avec diverses chambres de mesure pour une intégration flexible dans n'importe quel système de tuyauterie à l'aide de connecteurs rapides ou à emboîter.

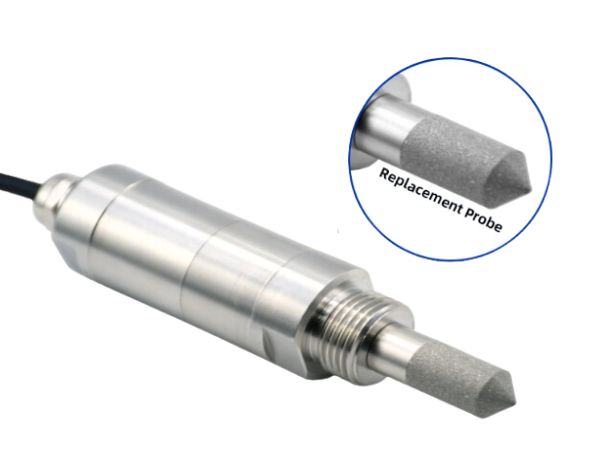

Mesureur de point de rosée industriel portatif

- Série HG970

Caractéristiques principales

Le HG970 est conçu pour des performances exceptionnelles dans les environnements industriels, avec une sonde métallique durable et remplaçable qui garantit une longue durée de vie et une installation facile.

Cet appareil de poche est conçu pour fournir des données rapidement et avec précision, avec un temps de réponse rapide considérablement amélioré par une fonction de purge du capteur pour une détection rapide et précise de l'humidité.

Des mesures fiables dans des conditions exigeantes :

Le capteur robuste du HG970 résiste à la condensation et se remet complètement de l'exposition à l'humidité, fournissant des lectures fiables même dans des conditions difficiles.

Interface utilisateur intuitive pour une meilleure convivialité :

Le HG970 est équipé d'un écran graphique LCD facile à utiliser qui offre une visualisation claire des données. Son interface intuitive, associée à des capacités étendues d'enregistrement des données, en fait l'outil idéal pour une analyse complète de l'humidité en déplacement.

Le HG970meter est parfait pour les professionnels qui ont besoin de mesures rapides et précises du point de rosée et de performances fiables dans divers environnements industriels.

Pourquoi mesurer le point de rosée dans l'air comprimé ?

Les mesures du point de rosée utilisées dans les systèmes d'air comprimé sont cruciales pour plusieurs raisons, en particulier dans les environnements industriels où la qualité de l'air a un impact direct sur le fonctionnement et l'efficacité de l'équipement et des processus pneumatiques. Les raisons suivantes sont essentielles et nous les avons énumérées :

Prévenir les dégâts causés par l'humidité: L'air comprimé contient souvent de l'humidité, qui peut se condenser en gouttelettes d'eau si la température de l'air tombe en dessous du point de rosée. Cette condensation peut entraîner la corrosion et l'endommagement des tuyauteries, des équipements et des instruments. En mesurant le point de rosée, vous pouvez vous assurer que la teneur en humidité de l'air comprimé est à un niveau sûr pour éviter de tels dommages.

Garantir la qualité des produits: Dans de nombreux processus de fabrication, notamment dans les secteurs pharmaceutique, électronique et alimentaire, l'humidité peut compromettre la qualité du produit. Par exemple, une humidité excessive peut affecter les processus de revêtement, créer des défauts dans la peinture ou entraîner une contamination. Les mesures du point de rosée permettent de maintenir les normes de qualité de l'air requises pour garantir l'intégrité du produit.

Efficacité énergétique: Faire fonctionner un sécheur pour réduire l'humidité de l'air comprimé consomme de l'énergie. En mesurant et en contrôlant avec précision le point de rosée, les industries peuvent optimiser le fonctionnement des sécheurs d'air, en s'assurant qu'ils ne sont utilisés que lorsque c'est nécessaire, ce qui permet d'économiser de l'énergie et de réduire les coûts d'exploitation.

Respect des normes: Diverses industries sont régies par des normes qui imposent des niveaux spécifiques de qualité de l'air, y compris la teneur en humidité. La mesure du point de rosée est une méthode directe pour vérifier la conformité à ces normes, telles que la norme ISO 8573-1, qui définit les niveaux de qualité de l'air, y compris l'humidité.

Sécurité: Dans les processus où l'air comprimé entre en contact avec des matériaux hautement réactifs ou est utilisé dans des environnements présentant un risque d'explosion, le contrôle de l'humidité est essentiel. L'humidité dans l'air comprimé peut augmenter de manière significative le risque d'incendie et d'explosion dans de tels environnements.

Fiabilité opérationnelle: Une mesure et un contrôle appropriés du point de rosée peuvent accroître la fiabilité des outils pneumatiques et des équipements alimentés par de l'air comprimé. L'humidité peut entraîner des dysfonctionnements des systèmes pneumatiques, des besoins de maintenance fréquents et une réduction de la durée de vie des équipements.

Quoi qu'il en soit, la surveillance du point de rosée dans les systèmes d'air comprimé est essentielle pour maintenir la fiabilité des équipements, garantir la qualité des produits, améliorer l'efficacité énergétique, se conformer aux normes industrielles et assurer la sécurité dans les environnements de fabrication.

Comment choisir un capteur de point de rosée pour l'air comprimé ?

Le choix du bon capteur de point de rosée pour un système d'air comprimé est essentiel pour assurer une surveillance et un contrôle précis de l'humidité, ce qui peut avoir un impact considérable sur l'efficacité du système et la qualité du produit.

Voici quelques éléments clés à prendre en compte lors de la sélection d'un capteur de point de rosée :

- Plage de mesure: Assurez-vous que le capteur couvre les températures extrêmes auxquelles votre système peut être confronté.

- Précision: Optez pour une précision et une répétabilité élevées afin de maintenir un contrôle précis de l'humidité.

- Temps de réponse: Choisissez un capteur qui réagit rapidement aux changements de conditions.

- Pression de fonctionnement: Sélectionnez un capteur adapté à la pression du système pour garantir la durabilité et la précision des relevés.

- Résistance aux contaminants: Choisissez un capteur résistant aux huiles, aux produits chimiques ou aux particules présentes dans votre environnement.

- Facilité d'installation et d'entretien: Favoriser les capteurs simples à installer et à entretenir.

- Sortie et connectivité: Assurez-vous de la compatibilité avec vos systèmes de surveillance existants, en envisageant des options telles que des sorties 4-20 mA, 0-10 V ou numériques.

- Conditions environnementales: Vérifiez que le capteur peut résister aux conditions environnementales spécifiques auxquelles il sera confronté.

- Coût et garantie: Adaptez le coût du capteur à votre budget et donnez la priorité à une bonne garantie pour plus de sécurité.

En tenant compte de ces facteurs, vous pouvez choisir un capteur de point de rosée qui répond aux besoins spécifiques de votre système d'air comprimé, assurant ainsi un fonctionnement efficace et une protection contre les problèmes liés à l'humidité.

Produits apparentés

TROUVER LE BON TRANSMETTEUR DE TEMPÉRATURE ET D'HUMIDITÉ

Faites-nous part de votre projet dès aujourd'hui

Dites-nous quels sont les détails de votre projet de moniteur,

Nous vous proposerons la meilleure solution à des prix compétitifs dans un délai de 3 jours.

Nous vous proposerons la meilleure solution à des prix compétitifs dans un délai de 3 jours.

FAQ

Qu'est-ce qu'un capteur de point de rosée pour l'air comprimé et pourquoi est-il important ?

- Un capteur de point de rosée est un dispositif qui mesure le point de rosée de l'air comprimé. Le point de rosée est la température à laquelle la vapeur d'eau contenue dans l'air se condense en eau liquide. Dans les systèmes d'air comprimé, l'humidité peut causer un certain nombre de problèmes, notamment :

- Corrosion des canalisations et des équipements

- Réduction de l'efficacité des outils et des machines pneumatiques

- Développement de moisissures et de bactéries

- Contamination des produits

En mesurant le point de rosée de l'air comprimé, vous pouvez vous assurer que l'air est suffisamment sec pour éviter ces problèmes. Cela peut vous aider à économiser de l'argent sur les coûts de maintenance, à améliorer la qualité des produits et à prolonger la durée de vie de votre système d'air comprimé.

Quels sont les différents types de capteurs de point de rosée pour l'air comprimé ?

Il existe deux principaux types de capteurs de point de rosée pour l'air comprimé :

- Capteurs de point de rosée à miroir réfrigéré : Ces capteurs fonctionnent en refroidissant un miroir jusqu'à ce que de la vapeur d'eau se condense à sa surface. La température à laquelle la condensation se produit est le point de rosée. Les capteurs de point de rosée à miroir réfrigéré sont très précis, mais ils peuvent être coûteux et nécessitent une maintenance régulière.

- Capteurs de point de rosée à capacité électrique : Ces capteurs mesurent le changement de capacité électrique d'un matériau lorsqu'il absorbe de l'humidité. Les capteurs de point de rosée à capacité électrique sont moins coûteux que les capteurs à miroir froid et sont généralement plus faciles à entretenir. Cependant, ils peuvent ne pas être aussi précis que les capteurs à miroir froid, en particulier lorsque le point de rosée est très bas.

Quels sont les facteurs à prendre en compte lors du choix d'un capteur de point de rosée pour l'air comprimé ?

Lorsque vous choisissez un capteur de point de rosée pour l'air comprimé, vous devez tenir compte des facteurs suivants :

- La précision requise : Quelle est l'importance d'une mesure très précise du point de rosée ?

- La plage du point de rosée : Quelle est la plage attendue des points de rosée dans votre système d'air comprimé ?

- La pression et la température de l'air comprimé : Certains capteurs de point de rosée ne sont pas adaptés à l'utilisation d'air comprimé à haute pression ou à haute température.

- La facilité d'utilisation et d'entretien : Quelle est la facilité d'installation, d'étalonnage et d'entretien du capteur ?

- Le coût : Combien êtes-vous prêt à dépenser pour un capteur de point de rosée ?

À quelle fréquence dois-je étalonner mon capteur de point de rosée ?

La fréquence d'étalonnage d'un capteur de point de rosée dépend du capteur et de l'application. Toutefois, il est généralement recommandé d'étalonner les capteurs de point de rosée au moins une fois par an. Certains capteurs peuvent nécessiter un étalonnage plus fréquent, en fonction de l'utilisation et de l'environnement.

Où dois-je installer un capteur de point de rosée dans mon système d'air comprimé ?

L'emplacement idéal d'un capteur de point de rosée dépend de votre système d'air comprimé. Toutefois, voici quelques lignes directrices générales :

- Installation du capteur après le sécheur d'air pour contrôler les performances du sécheur.

- Installer le capteur à un endroit où l'air comprimé est utilisé dans une application critique.

- Éviter les endroits où le capteur peut être exposé à des températures extrêmes ou à des contaminants.

Répandre le monde

HENGKO est un leader mondial dans le domaine des solutions de capteurs industriels, réputé pour son design unique et ses excellentes performances. Nos transmetteurs et capteurs de température et d'humidité sont utilisés dans une large gamme d'industries, y compris l'alimentation et les boissons, les produits pharmaceutiques, la fabrication et la surveillance de l'environnement.

0

+

Années d'expérience

0

Ventes dans le monde entier

0

K

Projets industriels

Autres projets populaires

Caves à vin

Perfectionner la conservation : Gérer la température et l'humidité pour le vieillissement du vin

Hôpitaux et laboratoires

Précision dans les soins de santé : Garantir des environnements stériles et stables

Entrepôts agricoles

Optimisation du stockage des récoltes : Stabiliser les conditions après la récolte