Dew Point Sensor for Air Dryer

Optimalkan Sistem Udara Anda dengan Pemantauan Titik Embun Tingkat Lanjut

Beranda " Dew Point Sensor for Air Dryer

Dew Point Sensor for Industrial Compressed Air Dryer Solution Supplier

Leading Provider of Dew Point Sensors for Industrial Compressed Air Dryer Solutions - HENGKO

HENGKO is one of professional supplier of dew point sensors for industrial compressed air dryer solutions. We supply kinds of temperatture humidity transmitter and sensor for widely used industrial humidity and temperature monitor.

- High Quality: Our sensors are built to last and perform reliably.

- Accurate Monitoring: Precise measurement of moisture levels to keep your systems in check.

- Prevent Damage: Helps to avoid system failures and costly repairs.

- Efficient Performance: Ensures optimal performance of your industrial applications.

- Aplikasi Serbaguna: Suitable for a wide range of industrial uses for compressed air dryer system.

Pengukuran Titik Embun Industri Online - HG602

Fitur utama

HG602 dirancang untuk presisi dan keandalan, memberikan pengukuran titik embun yang penting untuk manajemen sistem udara tekan yang efisien.

- Rentang Pengukuran-50°C hingga +20°C, sempurna untuk beragam kondisi pengoperasian.

- Kemampuan Tekanan: Menangani tekanan dari -0,1 hingga 5,0 MPa dengan konfigurasi tekanan tinggi opsional hingga 35 MPa (350 bar).

- Keluaran dan Komunikasi: Menawarkan output digital 4-20mA dan HENGKO untuk diintegrasikan dengan sistem kontrol yang ada.

- Catu Daya: Pengoperasian yang efisien dengan 12-30Vdc pada 60mA.

- Fleksibilitas Instalasi: Desain ringkas dengan ulir jantan G1/2″ dan rating IP65 untuk pemasangan yang mudah dan aman.

- Teknologi Sensor yang Disempurnakan: Dilengkapi sensor yang baru dikembangkan untuk meningkatkan stabilitas sinyal dan keandalan jangka panjang hingga -50°C.

- Opsi Pemasangan Serbaguna: Kompatibel dengan berbagai ruang pengukuran untuk integrasi yang fleksibel ke dalam skema perpipaan apa pun menggunakan konektor push-fit atau konektor cepat.

Online Dew Point Transmitter Series

Wall Mounted Dew Point Transmitter Series

Pengukur Titik Embun Industri Genggam

- Seri HG970

Fitur utama

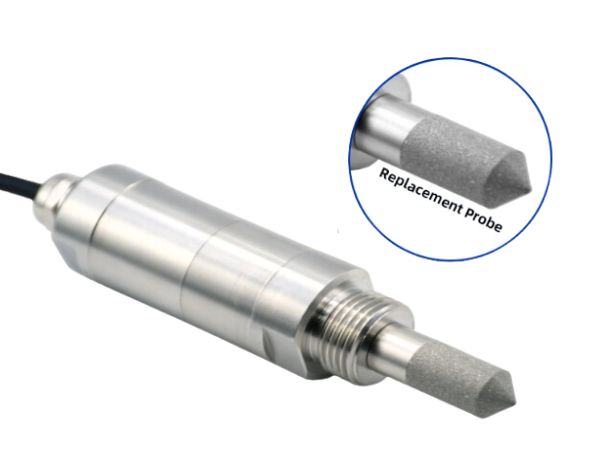

HG970 direkayasa untuk kinerja luar biasa di lingkungan industri, menampilkan desain probe logam yang tahan lama dan dapat diganti yang memastikan masa pakai yang lama dan pemasangan yang mudah.

Pengukur genggam ini dirancang untuk menghasilkan data dengan cepat dan akurat, dengan waktu respons yang cepat yang secara signifikan ditingkatkan oleh fungsi pembersihan sensor untuk deteksi kelembapan yang cepat dan tepat.

Pengukuran yang Dapat Diandalkan dalam Kondisi yang Menuntut:

Sensor HG970 yang tangguh tahan terhadap kondensasi dan pulih sepenuhnya dari paparan kelembapan, sehingga memberikan pembacaan yang dapat diandalkan, bahkan dalam kondisi yang menantang.

Antarmuka Pengguna yang Intuitif untuk Peningkatan Kegunaan:

HG970 dilengkapi dengan layar LCD grafis yang mudah digunakan yang menawarkan visualisasi data yang jelas. Antarmuka yang intuitif ditambah dengan kemampuan pencatatan data yang ekstensif menjadikannya alat yang ideal untuk analisis kelembapan yang komprehensif di mana saja.

HG970meter sangat cocok bagi para profesional yang membutuhkan pengukuran titik embun yang cepat, akurat, dan kinerja yang dapat diandalkan dalam berbagai pengaturan industri.

Why It is so import to Monitor Dew-Point in Air Dryer System?

Monitoring the dew point in an air dryer system is crucial for several reasons:

Prevents Corrosion and Equipment Damage: Water vapor in compressed air can condense into liquid water when temperatures drop below the dew point. This moisture can lead to rust and corrosion within pipes, tanks, and other equipment. This can significantly weaken the system and lead to expensive repairs or replacements.

Ensures Optimal Performance of Equipment: Many pneumatic tools and machinery rely on clean, dry air to function correctly. Moisture can cause malfunctions, reduced efficiency, and even complete failure.

Maintains Product Quality: In processes like spray painting, moisture in the compressed air can cause imperfections or defects in the final product.

Optimizes Dryer Performance: Regular dew point monitoring allows you to ensure your air dryer is functioning properly and removing moisture to the desired level. This can help identify potential problems with the dryer early on and prevent costly repairs.

Extends Maintenance Intervals: By keeping the dew point under control, you can lessen wear and tear on your equipment, leading to extended maintenance intervals and lower overall costs.

In short, monitoring dew point is essential for protecting your equipment, ensuring efficient operation, and maintaining product quality in compressed air systems.

What Factor You Should Care When Choose Dew Point Sensor for Your Air Dryer Device ?

Here are some key factors by our experience you should consider when choosing a dew point sensor for your air dryer device:

Accuracy and Reliability: This is arguably the most important factor. The sensor needs to consistently measure extremely low moisture levels to ensure your compressed air meets the required dryness specifications. Look for sensors with high accuracy ratings and a proven track record of reliability.

Waktu Respon: The sensor should be able to detect changes in dew point quickly. This is particularly important for systems where moisture content can fluctuate rapidly. A fast response time allows for prompt corrective action if the dew point rises above the desired level.

Stabilitas: Over time, some sensors can drift, meaning their readings become less accurate. Choose a sensor with good long-term stability that minimizes drift and requires minimal recalibration.

Contaminant Resistance: Compressed air can contain oil vapors and particulates. The sensor should be resistant to these contaminants to ensure accurate readings and avoid malfunction. Some sensors may require filters to protect them from contamination.

Ease of Maintenance and Calibration: Regular maintenance and calibration are essential for any dew point sensor. Consider how easy it is to access the sensor for maintenance and how often calibration is required.

Operating Environment: Consider the temperature and pressure range the sensor will be operating in. Make sure the sensor is rated for the conditions within your air dryer system.

Consulting with a compressed air system specialist can be helpful in choosing the right dew point sensor for your specific application. They can help you assess your needs and recommend sensors that meet your requirements.

Produk Terkait

TEMUKAN PEMANCAR SUHU & KELEMBABAN YANG TEPAT

Beri Tahu Kami Proyek Anda Hari Ini

Beritahu Kami Detail Proyek Monitor Anda,

Kami akan memberikan solusi terbaik dengan harga yang kompetitif dalam waktu 3 hari.

Kami akan memberikan solusi terbaik dengan harga yang kompetitif dalam waktu 3 hari.

Menyebarkan Dunia

HENGKO adalah pemimpin global dalam solusi sensor industri, dengan reputasi untuk desain yang unik dan kinerja yang sangat baik. Pemancar dan sensor suhu dan kelembaban kami digunakan di berbagai industri, termasuk makanan dan minuman, farmasi, manufaktur, dan pemantauan lingkungan.

0

+

Pengalaman Bertahun-tahun

0

Penjualan di Seluruh Dunia

0

K

Proyek Industri

Proyek Populer Lainnya

Gudang Anggur

Menyempurnakan Pengawetan: Mengelola Suhu dan Kelembaban untuk Penuaan Anggur

Rumah Sakit dan Laboratorium

Presisi Perawatan Kesehatan: Memastikan Lingkungan yang Steril dan Stabil

Gudang Pertanian

Optimalisasi Penyimpanan Tanaman: Menstabilkan Kondisi Pasca Panen