Pendahuluan

Dew point monitoring plays a crucial role in various industries where humidity control is essential. The dew point is the temperature at which air becomes saturated with moisture and begins to condense, making it a critical parameter for maintaining optimal environmental conditions.

Whether you’re working with compressed air systems, manufacturing delicate products, or ensuring quality control in food storage, managing the dew point can prevent costly equipment damage, contamination, and product spoilage.

In this article, we will explore the common applications of dew point monitoring across multiple industries, highlighting how accurate measurements can ensure system efficiency, product quality, and safety.

What is the Dew Point?

The titik embun is the temperature at which air can no longer hold all the water vapor it contains. When the air is cooled to its dew point, it reaches a state of 100% relative humidity, meaning it’s holding as much water vapor as it can at that temperature. If the air is cooled below the dew point, the excess water vapor will condense into liquid water.

Understanding of Dew Point Sensor

Dew point sensors, also known as dew point transmitters or dew point meters, are devices used to measure the temperature at which air becomes saturated with water vapor, known as the dew point. Here’s a explanation of how dew point sensors work:

Detection Principle: Dew point sensors operate on the principle that the electrical properties of certain materials change when they come into contact with water. This change can be measured to determine the presence of moisture.

Sensor Design: The sensor typically consists of a probe that is exposed to the air. The probe is made of a material that has a known and predictable response to the presence of water.

Measurement Process: When the air cools down to its dew point, water vapor condenses on the probe. This condensation is detected by the sensor, which then measures the temperature at which this condensation occurs.

Signal Conversion: The sensor converts the physical change caused by condensation into an electrical signal. This signal is proportional to the humidity level.

Data Transmission: The electrical signal is then transmitted to a display unit or a monitoring system where it can be read or recorded.

Output: The sensor provides an output that can be used to control systems, trigger alarms, or for data logging and analysis.

Common Applications of Dew Point Monitoring

Dew point monitoring is an essential practice across various industries, ensuring that humidity levels are controlled and moisture-related problems are avoided. Below are some common applications of dew point monitoring and how does sensor used:

1. Sistem Udara Terkompresi

In industries where compressed air is used (e.g., manufacturing, automotive, food and beverage, pharmaceuticals), it’s critical to ensure that the air is dry.

Dew point sensors are installed in air compressor systems to continuously monitor moisture levels in the compressed air.

If the dew point exceeds a set threshold, the system triggers alarms or activates dryers to reduce moisture levels.

Ensures that the air remains at the appropriate dew point for the intended application (e.g., below -40°C for critical applications).

2. HVAC (Heating, Ventilation, and Air Conditioning) Systems

High humidity levels can lead to mold growth, condensation on surfaces, and discomfort in HVAC systems.

Sensors monitor the dew point of the indoor air to regulate humidity levels, ensuring they stay within optimal comfort ranges (typically 40-60% relative humidity).

In colder environments, such as data centers or refrigerated spaces, it ensures that air doesn’t cool below the dew point, which could lead to water condensation and damage to equipment.

3. Food and Beverage Industry

Dew point monitoring ensures that the processing, packaging, and storage of food products happen under controlled humidity conditions to prevent spoilage, mold growth, or degradation.

Dew point sensors are used in food storage and packaging areas, especially in environments like warehouses, refrigerated storage, and production lines.

They help maintain optimal humidity levels for different food products (e.g., dry foods require lower humidity).

Prevents moisture from condensing on food surfaces, which could promote the growth of harmful bacteria or mold.

4. Pharmaceutical Manufacturing and Storage

Pharmaceuticals and active pharmaceutical ingredients (APIs) are highly sensitive to moisture, which can degrade their efficacy or lead to contamination.

In manufacturing areas (e.g., tablet coating, packaging) and storage facilities (e.g., warehouses, controlled storage rooms), transmitters ensure a dry environment.

In cleanrooms and controlled environments, sensors ensure that humidity levels do not exceed safe levels, thus preventing condensation and ensuring product integrity.

Sensors help maintain ideal conditions for the production of moisture-sensitive drugs, vaccines, or biologics, preventing potential reactions or spoilage.

5. Semiconductor Manufacturing

In semiconductor manufacturing, Dew point sensors are used in cleanrooms and controlled manufacturing areas to make sure that the dew point remains well below the freezing point (typically around -40°C or lower).

Moisture in the air can affect the manufacturing of chips, cause defects in the production process, and lead to contamination of critical materials.

In gas systems used in semiconductor production (such as nitrogen or hydrogen), dew point sensors help ensure that gases are dry to avoid reactions or impurities.

6. Gas and Petrochemical Industries

Excess moisture in gas pipelines and petrochemical plants can lead to issues like corrosion, blockages, and reduced operational efficiency. Dew point sensors are essential for monitoring systems such as natural gas, nitrogen, and hydrogen, ensuring the gas remains sufficiently dry.

In natural gas transmission, these sensors prevent the formation of liquids within pipelines, reducing the risk of damage and blockages.

Similarly, in refineries and petrochemical plants, moisture poses a significant threat to sensitive equipment such as compressors, storage tanks, and reactors. By maintaining a dry environment, dew point sensors protect equipment integrity.

7. Industrial Dryers

Industries like textiles, pharmaceuticals, and food production rely on precise moisture control to ensure product quality and safety. Dew point sensors play a vital role in these processes by monitoring and regulating the relative humidity and temperature in drying systems.

For example, in pharmaceuticals, controlling the dew point within drying chambers prevents over- or under-drying, preserving ingredient stability. In textiles, managing moisture content in fabrics helps maintain quality and prevents mold growth.

8. Petroleum and Natural Gas Extraction

During the extraction and transportation of petroleum and natural gas, managing moisture levels is crucial to avoid issues such as corrosion, hydrate formation, and blockages. Dew point sensors are installed in gas pipelines to measure moisture levels and prevent the formation of condensates, like water or hydrocarbons. These sensors are also key in avoiding hydrate buildup, which can obstruct pipelines and cause operational shutdowns.

Pilih Pemancar Suhu dan Kelembaban Titik Embun yang Tepat

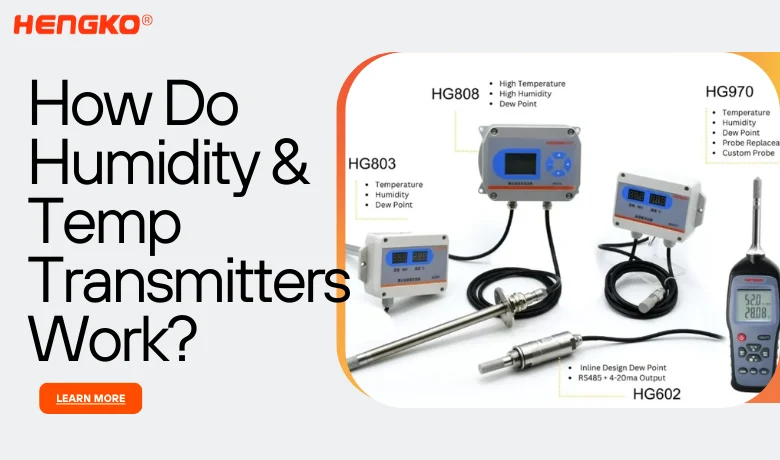

When it comes to monitoring temperature and humidity in various applications, selecting the right dew point sensor is critical. HENGKO offers a comprehensive range of dew point temperature and humidity transmitters, each designed to meet the unique needs of different industries and environments. Whether you require inline, handheldatau wall-mounted solutions, HENGKO provides reliable, high-performance transmitters to ensure optimal conditions in your operations.

Tailored Solutions for Every Industry

Gas and Petrochemical: Inline sensors for pipeline and refinery monitoring

Cleanrooms and Controlled Environments: Handheld and wall-mounted options for maintaining sterile conditions

Industrial Drying and Manufacturing: Real-time monitoring with inline sensors to ensure optimal material moisture levels

Ready to Optimize Your Environmental Monitoring?

Explore our full range of dew point transmitters and find the perfect solution for your application. Contact us at sales@hengkometer.com for more information and personalized recommendations.