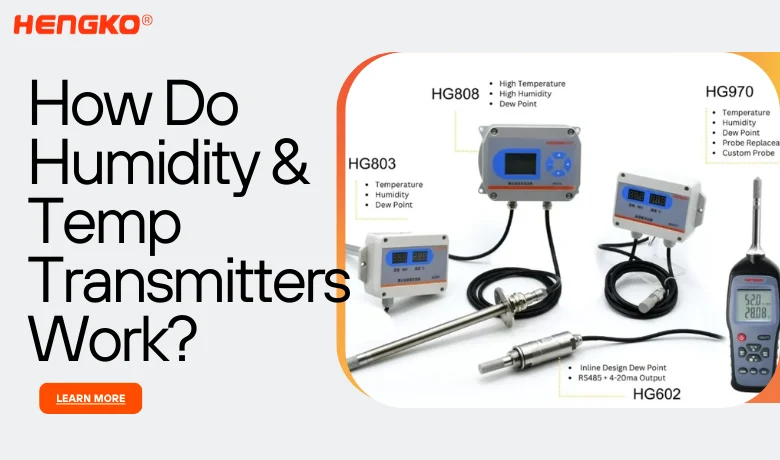

湿度・温度トランスミッタの仕組み

In short, Humidity and temperature transmitters measure and send environmental data to control systems. They are widely used in HVAC, pharmaceuticals, food processing, and cleanrooms where precise conditions are critical. Sensing: Built-in humidity and temperature sensors detect moisture and heat changes. Signal Conversion: The device converts raw signals into standard outputs like 4–20 mA or Modbus. Data Transmission: Data is sent to monitoring or automation systems for real-time control. Introduction In industries, even small changes in temperature or humidity can cause major issues, like product defects in pharmaceutical cleanrooms or static damage in data centers. Unlike basic home sensors, industrial transmitters offer high accuracy, durability, and easy integration with control […]

なぜドライヤー露点計は圧縮空気システムにとって重要なのか?

Why Are Dryer Dew Point Meters Critical for Compressed Air Systems? Maybe You always battle hidden moisture in compressed air that can cause corrosion, freezing, and product defects. By installing dew point meters, you detect and stop moisture issues before equipment fails. You can monitor dew point to prevent condensation and protect assets. The HENGKO HG970 series provides continuous dew point readings with 4–20 mA and Modbus RTU outputs, onboard logging, and diagnostics—so you can close the loop for control and energy savings. Here, this guide explains the causes of moisture, how to choose sensors, where to place them, and how to integrate the HENGKO HG970 so you can act […]

湿度トランスミッターを使ったオフィス内の湿度調整方法とは?

Why One Office Zone is Too Humid & How a Humidity Transmitter Fixes It Persistent humidity in one office zone can disrupt comfort, increase mold risk, and hurt productivity. Even with your HVAC system running, one area may stay damp due to hidden airflow issues or localized moisture sources. A humidity transmitter acts like a diagnostic tool, revealing real-time, zone-specific data so you can fix problems faster. Why Does Humidity Vary Zone-to-Zone Despite HVAC Efforts? Humidity imbalances plague many offices. HVAC systems often struggle to maintain uniform conditions across all spaces. Zone-specific factors like airflow gaps or uneven heat loads create microclimates. Snippet Answer: Persistent humidity usually comes from uneven […]

冷凍式空気乾燥機の温度と湿度を監視する理由

はじめに 圧縮空気は、電気、水、ガスと並んで、近代産業における「第4のユーティリティ」と呼ばれることが多い。しかし、圧縮空気システムが直面する最も一般的な問題の1つは湿気です。湿気は未処理の場合、腐食、パイプラインの詰まり、空気圧機器の損傷、製品品質の低下につながります。この問題に対処するため、一般に「コールドドライヤー」として知られる冷凍式エアドライヤが、圧縮空気中の湿気を低減する効率的な手段として広く使用されています。しかし、冷凍式ドライヤーは効果的ですが、その性能は安定した環境制御に大きく依存します。そこで、温度・湿度トランスミッターが活躍します。これらのトランスミッターは、重要なパラメーターを継続的に監視することで、ドライヤーが最適な条件下で運転されることを保証し、両者の安全を守ります。

高精度温湿度モニタリング・デバイスで半導体製造を守る

1.はじめに 半導体産業は、あらゆる製造部門の中でも最も厳しい環境条件の下で操業している。デバイスがナノスケールに微細化し、製造工程がますます複雑化するにつれて、環境パラメータ、特に温度と湿度を正確に制御し続けることは、安定した品質と歩留まりを確保するために不可欠となっています。温度や湿度がわずかに変動するだけでもプロセスの安定性に影響を与え、フォトリソグラフィーのアライメント、エッチング精度、材料成膜にばらつきが生じます。これらは、製品の信頼性、生産スループット、長期的なデバイス性能に影響を与えます。このような課題を考えると、リアルタイムの温湿度モニタリングは単なるベストプラクティスではなく、基本的な要件です。堅牢な環境モニタリングは、プロセスの完全性を維持し、ダウンタイムを削減し、コンプライアンスを確保するのに役立ちます。

温湿度トランスミッタがチャンバー内の精度を保証する方法

はじめに 環境シミュレーションや信頼性試験の世界において、恒温恒湿槽は、エレクトロニクスや製薬から材料科学や航空宇宙まで、幅広い産業で不可欠なツールとなっています。これらの恒温恒湿槽は、正確に制御された気候を維持するように設計されており、長時間の試験サイクルにおいて安定した温度と相対湿度(RH)を保証します。しかし、何がこのレベルの精度を可能にしているのでしょうか?すべての高性能チャンバーの中核には、重要でありながら見落とされがちなコンポーネント、温度・湿度トランスミッターがあります。温度・湿度トランスミッターは、チャンバーの "センサリー・システム "として、継続的に環境条件をモニターし、リアルタイム・データをコントロール・ユニットに伝え、正確な調整と安定化を可能にします。この記事では、[...]について掘り下げていく。

露点センサーの種類と動作原理:どのように動作するのか?

露点センサが産業効率にどのような影響を与えるか、ご存知ですか?露点センサは、環境制御の維持、腐食の防止、製品の品質確保など、さまざまな分野で重要な役割を果たしています。露点センサーは、さまざまな手法で湿度を測定し、空気中の水分が凝縮して液体になる温度を検出します。露点として知られるこの温度は、産業における効果的な湿度管理に不可欠です。露点温度の重要性は、工業プロセスにおけるその役割を考えれば明らかです。適切な露点制御を行わなければ、部品は腐食、機械的故障、汚染に直面する危険性があります。リアルタイムモニタリングは湿度管理に役立ち、製品の品質を向上させます。露点測定技術の種類:どのような [...]

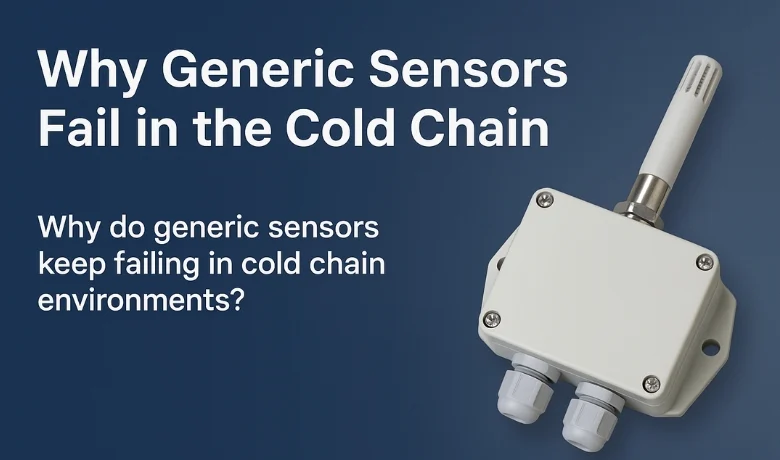

汎用センサーがコールドチェーンで失敗する理由

なぜ一般的なセンサーはコールドチェーン環境で故障し続けるのか?それは、単にそのために作られていないからです。コールドチェーンロジスティクスでは、精度、耐久性、迅速な応答性が求められます。超低温や結露、輸送中の振動など、コールドチェーンではセンサーが試されます。そしてセンサーが故障すると、ワクチンの腐敗、出荷の拒否、食品の安全性の低下など、大きな代償を払うことになります。このブログでは、一般的なセンサーでは不十分な場合が多い理由、不正確な読み取りがもたらす隠れたリスク、そして適切な工業用センサーやトランスミッターを選択することで、貴社の製品や評判をどのように守ることができるかをご紹介します。コールドチェーン・モニタリングの責任者であれば、この [...]...

信頼性の高い温度・湿度センサーで発酵の歩留まりを高める

現代のバイオ製造において、発酵は抗生物質、酵素、アミノ酸、バイオ燃料など、製品の収量、純度、一貫性に直接影響する重要なステップです。発酵が成功する背景には、正確な生物学的プロセスだけでなく、厳密に制御された環境がある。あらゆる環境要因の中でも、温度と湿度は最も影響力が大きく、かつ管理が難しい要因です。この記事では、発酵環境の中核となるモニタリング要件を探り、このアプリケーションに合わせた高度なソリューションであるHG808-H温湿度トランスミッタを紹介します。発酵とは?発酵とは、バクテリア、酵母、真菌などの微生物が、嫌気的条件下で有機化合物(通常は炭水化物)をアルコール、酸、ガスに変換する代謝プロセスです。この [...]

製紙におけるスマートな湿度管理

製紙業界では、環境管理は単なる技術的な細部ではなく、重要な品質要素です。紙はもともと吸湿性の素材です。つまり、周囲の空気条件によって湿気を吸収したり放出したりするのです。温度と湿度が一定に保たれていないと、紙はゆがんだり、もろくなったり、カビが生えたりすることがあります。パルプ化エリアの熱と蒸気から、完成したロールの静かな保管室に至るまで、生産の各段階には独自の環境上の課題があります。製品の品質とプロセスの安定性を維持するために、メーカーはインテリジェントなモニタリングシステムに注目しています。製紙プロセスにおける環境問題 1.パルプ化エリア - [...]...