HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more

Reliable OEM Partner for Dew Point Monitoring in Compressed Air, Gas, and Drying Systems

ホーム " 露点計

Designed for precision and durability, the HENGKO HG970 series offers a reliable dew point monitoring solution for demanding industrial environments. With high accuracy, fast response time, and robust stainless steel construction, the HG970 is ideal for continuous online measurement in compressed air systems, gas drying lines, and moisture-sensitive production processes. Whether you need analog or digital output, the HG970 series ensures stable performance and seamless integration into your control systems.

HG970 Series Dew Point Meter/ Temperature Humidity Selection Guide

| モデル | 温度範囲 | Measurement Ranges (Humidity / Dew Point / Wet Bulb) | Accuracy (Temp / RH / Dew Point) | プローブタイプ | 申し込み | Features / Notes |

| HG970 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Replaceable Probe | General-purpose monitoring in HVAC systems, laboratories, and industrial rooms | Standard model with easy-to-replace probe for regular maintenance |

| HG972 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Round Probe | Compact systems like environmental test chambers, storage cabinets, or small control boxes | Space-saving round probe for tight installations |

| HG984 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | OEM Sharp Probe | OEM integration in compact equipment, sensor assemblies, or instrument panels | Custom sharp probe for embedded and OEM applications |

| HG983 | -30 ~ 100℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Long Sharp Probe | Compressed air pipelines, drying ovens, and tank inlets | Extended reach probe ideal for insertion into ducts or deep ports |

| HG981 | -30 ~ 120℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | OEM Long Probe | Lithium battery drying rooms, petrochemical high-temp gas lines | Long and durable probe for harsh, high-temperature applications |

| HG982 | -30 ~ 120℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Split Sharp Probe | Industrial dryers, heated air chambers, or environments with difficult access | Split design for easier installation and probe positioning |

HG970 Series

Portable Dew Point Meter HG970 – Precision in Your Pocket

The Portable Dew Point Meter is a lightweight, field-ready device designed for fast,

accurate humidity and dew point measurements in a wide range of environments.

*Compact & Portable – Ideal for mobile use in field inspections and remote sites

*High Accuracy – Advanced sensors ensure precise dew point readings

*Versatile Applications – Suitable for HVAC checks, industrial spot measurements, and environmental monitoring

*Rapid Response – Quickly adapts to changing conditions for real-time results

*User-Friendly Interface – Simple controls and clear display for effortless operation

*Durable & Lightweight – Built to withstand demanding field conditions without added bulk

*Essential Tool – A must-have for professionals requiring reliable moisture data on the go

HENGKOは、産業用センサーソリューションのグローバルリーダーであり、ユニークなデザインと優れた性能に定評があります。当社の温度・湿度トランスミッターとセンサーは、食品・飲料、製薬、製造、環境モニタリングなど、幅広い産業分野で使用されています。

特許を取得した自社設計の露点発信器シリーズをベースに、独自の露点センサー製品をフルカスタマイズすることができます。

費用対効果の非常に高い管理により、より低価格で競争力のある価格を得ることができます。

常にアップグレードし続ける製品で、変化し続ける市場のニーズにお応えします。

高解像度の商品画像、3D効果のあるクールなビデオなど、商品をうまく販売するための強力なマーケティング・サポートを受けることができます。

Dew Point Sensor for Compressed Air System Monitor : Ensuring Optimal Humidity Control and Air Quality for your Air Compress Machine

HENGKO is a trusted manufacturer of high-performance dew point transmitters, temperature and humidity transmitters, and portable dew point meters.

We specialize in delivering a comprehensive range of monitoring solutions tailored to meet the precise needs of industrial and environmental applications.

Engineered for accuracy, durability, and long-term stability, our products ensure reliable performance across demanding conditions. Whether you’re looking for a precise dew point sensor or a rugged humidity transmitter, HENGKO offers both the technology and expertise to support your project.

👉 Contact us today to explore customized solutions that fit your monitoring challenges.

A 露点計 is a precision instrument used to measure the dew point temperature—the temperature at which moisture in the air or gas begins to condense into liquid water. It is a key parameter for understanding humidity levels そして moisture content in various industrial and environmental applications.

対策 dew point temperature in °C or °F

Indicates humidity saturation in air or gases

Helps detect moisture contamination in compressed air, gases, or controlled environments

Compressed air systems (prevent water accumulation)

Gas drying processes (e.g. nitrogen, argon, hydrogen)

HVACシステム (ensure indoor climate control)

Lithium battery dry rooms (moisture-sensitive environments)

Pharmaceutical & food production (humidity-sensitive storage)

| タイプ | 説明 |

|---|---|

| Portable Dew Point Meter | Handheld, used for spot-checks and field diagnostics |

| Online Dew Point Transmitter | Fixed installation, sends real-time data to control systems (e.g. 4–20 mA, RS485) |

| Mirror-type Hygrometer | Laboratory-grade, ultra-accurate but costly |

Prevents corrosion, condensation, and product defects

Ensures compliance with industry standards (ISO, GMP, etc.)

Enhances energy efficiency and equipment lifespan

Checking the dew point with the HG970 series portable dew point meter from HENGKO is a precise, efficient, and reliable process designed for both industrial field inspections and laboratory-quality measurements. The HG970 series offers various probe configurations to suit a wide range of applications, from general HVAC systems to high-temperature drying environments. Below is a step-by-step guide and technical overview of how the dew point measurement is conducted using this instrument.

The HG970 series includes multiple probe types (e.g., replaceable, sharp, long, split) and temperature ranges (-30°C to 120°C), allowing users to choose the most suitable model based on their measurement environment. For example:

HG970 / HG972: Ideal for general industrial and HVAC applications.

HG981 / HG982: Recommended for high-temperature environments (80–120°C), such as lithium battery drying rooms and gas pipelines.

Ensure the device is powered (via external power supply or field setup).

Connect the probe securely to the test point, pipe port, or environmental chamber.

For accurate results, avoid exposing the sensor to sudden humidity shocks or contaminants like oil or dust before the reading stabilizes.

Once connected, the HG970’s built-in sensing module continuously samples the air or gas, measuring parameters such as:

Dew Point Temperature (°C or °F)

Relative Humidity (%RH)

Ambient Temperature (°C/°F)

These values are calculated using HENGKO’s advanced polymer capacitive or ceramic sensor technology, offering fast response time そして high accuracy even in dynamic or high-moisture environments.

If the model includes an LCD or digital interface (optional), the readings are displayed in real-time. For models without a display, the output is transmitted via:

Analog Signal (4–20 mA / 0–10 V)

Digital Communication (RS485 / Modbus-RTU)

These outputs can be logged via a data logger, PLC, or remote monitoring software.

The dew point temperature tells you the exact point at which condensation would occur under current pressure and humidity conditions. Lower dew points indicate drier air, which is critical for:

Preventing corrosion or moisture damage in pneumatic tools or compressed air systems

Maintaining strict humidity control in cleanrooms, dry rooms, or gas drying processes

For example:

Dew point < -40°C: Suitable for high-purity gas systems and lithium battery environments.

Dew point 0 ~ 10°C: Typical in HVAC, food storage, and general industrial applications.

To maintain reliable performance:

Calibrate the device periodically (typically once every 6–12 months) against a traceable standard.

Clean or replace the sensor probe as needed, especially if used in harsh or dusty environments.

Store the unit in a dry and clean place when not in use.

✅ Wide temperature and humidity range

✅ Interchangeable probe options for different environments

✅ Compact and robust construction for field use

✅ High accuracy and fast response time

✅ Optional OEM customization for unique industrial requirements

Contact HENGKO’s technical team at ka@hengko.com or visit www.hengkometer.com to get personalized advice based on your industry, installation method, and measurement conditions.

について HG970 series dew point transmitters from HENGKO are designed for industrial-grade dew point monitoring with high precision and stability. The normal dew point measurement range of the HG970 series is typically:

-60°C to +60°C Td (typical)

(Custom ranges available upon request)

| Parameter | 詳細 |

|---|---|

| Typical Range | -60°C ~ +60°C dew point (Td) |

| 湿度範囲 | 0%RH to 100%RH |

| 温度範囲 | -30°C to +120°C (varies by model, e.g., HG970 to HG982) |

| Sensor Type | Polymer capacitive or ceramic sensor (high accuracy, fast response) |

| 出力信号 | 4–20mA, 0–5V, 0–10V, RS485 / Modbus-RTU |

| 精度 | ±2°C Td typical (customizable based on sensor class) |

-60°C to -20°C Td: Ideal for compressed air drying systems, lithium battery dry roomsあるいは gas drying

-20°C to +20°C Td: Common in HVACシステム, pharmaceutical environmentsそして storage facilities

+20°C to +60°C Td: Suitable for high-moisture process areasあるいは climate chambers

If you need a customized dew point range, HENGKO can tailor the sensor configuration based on:

Target environment (dry gas, ambient air, high temp zone)

Accuracy requirement

Signal output preferences

📩 Contact: ka@hengko.com to request a custom specification or get technical support.

This is Great question!

Understanding the difference between 露点 そして 湿気 is key to accurately evaluating air moisture content

—especially in industrial, HVAC, and environmental monitoring applications.

| Aspect | 露点 | Humidity (Relative Humidity, %RH) |

|---|---|---|

| 定義 | について temperature at which air becomes fully saturated and water vapor condenses into liquid | について percentage of water vapor in the air compared to the maximum it can hold at a given temperature |

| Unit | °C or °F (Temperature) | %RH (Percentage) |

| Absolute/Relative? | Absolute measure of moisture content | Relative measure (depends on air temperature) |

| Temperature Dependent? | No – dew point is not affected by ambient temperature | Yes – higher temperatures can hold more moisture, affecting %RH |

| What it tells you | How dry or moist the air actually is | How close the air is to saturation at a given temperature |

| Used for | Precise control in drying, gas purity, industrial process monitoring | General comfort, climate control, environmental monitoring |

| Example | Dew point of -40°C = extremely dry air (used in lithium battery rooms) | 60%RH at 25°C = moderately humid air |

露点 = “How much water is really in the air?”

Relative Humidity = “How full is the air’s moisture tank at this temperature?”

| Ambient Temp | 露点 | Relative Humidity |

|---|---|---|

| 25°C | 10°C | ~45%RH |

| 25°C | 20°C | ~75%RH |

| 25°C | 24°C | ~95%RH |

用途 露点 for:

Compressed air drying systems

Inert gas monitoring (N₂, Ar, H₂)

Lithium battery dry rooms

用途 %RH for:

Indoor air quality

HVAC system control

Agricultural storage

Even though the temperature is the same, the dew point increases with more water vapor in the air, which raises the relative humidity.

Both devices are used to measure the dew point temperature, a critical parameter in determining moisture levels in air or gas. However, they differ significantly in design, applicationそして integration method.

| Aspect | 説明 |

|---|---|

| Measurement Function | Both measure dew point temperature accurately to detect moisture levels |

| Sensor Technology | Typically use similar capacitive or ceramic humidity sensors |

| Target Media | Both used with air, compressed gases, dry gases, etc. |

| アプリケーション | Found in industrial, HVAC, environmental monitoringそして gas drying |

| Feature / Aspect | 露点計 | 露点計 |

|---|---|---|

| Form Factor | Portable or handheld | Fixed-installation / inline sensor |

| Display | Built-in LCD or digital display | Usually no display (or optional), outputs data to external systems |

| Power Source | Battery-powered or rechargeable | Externally powered (e.g., 24V DC) |

| 出力信号 | Internal data logging, USB export (optional) | Analog (4-20 mA, 0-10V) or Digital (RS485/Modbus-RTU) |

| Use Case | On-site spot checks, mobile inspections | Continuous online monitoring & automation systems |

| User Type | Technicians, maintenance staff | Engineers, system integrators, automation specialists |

| インストール | Handheld use or temporary probe connection | Installed permanently in pipelines, dryers, tanks, etc. |

| Price Range | Generally higher due to display and portability features | More cost-effective for long-term embedded use |

| Typical Examples | Vaisala DM70, Michell MDM300, HG970 series | HENGKO HG970, Vaisala DMT143, E+E EE371 |

| Scenario | Recommended Device |

|---|---|

| Field diagnostics and mobile inspections | 露点計 |

| Continuous monitoring in a compressed air line | 露点計 |

| Temporary measurements in different locations | 露点計 |

| Integration into control/SCADA systems | 露点計 |

露点計 are portable tools designed for manual measurements, great for spot-checking and troubleshooting.

Dew Point Transmitters are installed devices built for long-term, real-time monitoring そして system automation.

The 4-20mA output is a popular choice for dew point sensors because it is a standard industrial output that is compatible with a wide range of control systems. It is also a very reliable and noise-resistant output, which makes it well-suited for use in harsh industrial environments.

Here are some of the advantages of using a 4-20mA output for dew point sensors:

互換性: The 4-20mA output is compatible with a wide range of control systems, including PLCs, DCSs, and SCADA systems. This makes it easy to integrate dew point sensors into existing control systems.

信頼性: The 4-20mA output is a very reliable output that is not susceptible to noise interference. This is important for dew point sensors, which are often used in harsh industrial environments.

正確さ: The 4-20mA output can provide accurate measurements of dew point. This is important for applications where precise dew point control is required.

範囲: The 4-20mA output can cover a wide range of dew point values. This makes it suitable for a variety of applications.

コストだ: The 4-20mA output is a relatively inexpensive output to implement. This makes it a cost-effective option for dew point sensors.

In addition to the advantages listed above, the 4-20mA output is also a very versatile output. It can be used to transmit a variety of other parameters, such as temperature, pressure, and flow rate. This makes it a valuable output for a wide range of industrial applications.

Here are some examples of applications where dew point sensors with 4-20mA outputs are commonly used:

Compressed air systems: Dew point sensors are used in compressed air systems to monitor and control the moisture content of the air. This is important for preventing corrosion and other damage to equipment.

HVACシステム: Dew point sensors are used in HVAC systems to control the humidity levels in buildings. This is important for human comfort and health.

Industrial drying processes: Dew point sensors are used in industrial drying processes to monitor and control the moisture content of the product being dried. This is important for ensuring the quality of the product.

Food and beverage processing: Dew point sensors are used in food and beverage processing to control the moisture content of the product being processed. This is important for ensuring the safety and quality of the product.

環境モニタリング: Dew point sensors are used in environmental monitoring stations to track changes in moisture content in the atmosphere. This information can be used to forecast weather conditions and to identify potential environmental problems.

As you can see, dew point sensors with 4-20mA outputs are a valuable tool for a wide range of industrial applications. They are reliable, accurate, and versatile, and they can be easily integrated into existing control systems.

The price of dew point transmitters can vary depending on the manufacturer, the features, and the accuracy of the transmitter. In general, dew point transmitters with higher accuracy and more features will cost more than dew point transmitters with lower accuracy and fewer features.

Based on my research, I would say that the price of dew point transmitters is generally fair. The cost of the components and the labor required to manufacture dew point transmitters is high, and the companies that manufacture dew point transmitters need to recoup these costs in order to stay in business. Additionally, dew point transmitters are used in a variety of critical applications, so it is important that they are reliable and accurate. The high price of dew point transmitters reflects the fact that they are high-quality instruments that can be trusted to provide accurate measurements.

Here are some factors that can affect the price of a dew point transmitter:

Here is a table of the price range of dew point transmitters on the market:

| タイプ | Price Range |

|---|---|

| Chilled mirror | $2,000 – $10,000 |

| Polymer | $500 – $2,000 |

| Metal oxide | $500 – $1,500 |

As you can see, the price range of dew point transmitters can vary depending on the type of transmitter. Chilled mirror dew point transmitters are the most expensive type of transmitter, but they are also the most accurate. Polymer and metal oxide dew point transmitters are less expensive, but they are also less accurate.

The price of dew point transmitters can also vary depending on the features of the transmitter. For example, dew point transmitters with data logging, alarm setpoints, and remote access capabilities will typically cost more than dew point transmitters with fewer features.

If you are looking for a high-quality dew point transmitter, I would recommend purchasing one from a well-known brand that has a good reputation for quality and reliability. You should also consider the features that are important to you and the accuracy that you require. If you are not sure which dew point transmitter is right for you, I would recommend consulting with a professional who can help you make an informed decision.

some questions about Dew Point Meter you like to know

A 露点計 is a precision instrument used to measure the dew point temperature — the temperature at which air or gas becomes saturated with moisture and water vapor begins to condense into liquid.

It works by sensing the relative humidity and temperature of the environment or gas stream, then calculating the dew point based on the current saturation level. Most modern dew point meters use capacitive or ceramic sensors for real-time measurements, offering high accuracy and stability across a wide range of industrial applications.

Dew point measurement is critical for moisture control, especially in applications where excess humidity can lead to equipment failure, corrosion, product spoilage, or safety risks.

Industries such as compressed air systems, pharmaceuticals, lithium battery manufacturing, semiconductorsそして food packaging depend on dew point monitoring to ensure dry environments and gas purity. In compressed air lines, for example, a low dew point prevents water buildup, which could otherwise damage tools and contaminate end products.

露点 は absolute temperature at which air becomes saturated and water vapor condenses, while humidity (usually relative humidity) is a percentage expressing how much moisture the air currently holds compared to its maximum capacity at a given temperature.

In simple terms:

露点 tells you how much moisture is actually in the air (in °C or °F).

Relative humidity tells you how close the air is to saturation (in %RH).

Dew point is more accurate for industrial applications, especially when monitoring drying processes or compressed air systems.

In industrial compressed air systems, the target dew point depends on the drying method そして application sensitivity:

| 申し込み | Recommended Dew Point |

|---|---|

| General industrial use | -20°C to -40°C |

| Instrumentation or electronics | -40°C to -70°C |

| Medical/Pharma cleanrooms | ≤ -40°C |

| Standard shop air (non-critical) | 0°C to -10°C |

A lower dew point means drier air, which is essential for high-performance or sensitive operations. The dew point meter helps monitor this and ensure system compliance.

Yes. Most dew point meters — including advanced portable models — can be used to measure dew point in a variety of non-corrosive gases, such as nitrogen (N₂), argon (Ar), carbon dioxide (CO₂)そして compressed natural gas (CNG).

However, it is important to verify:

Sensor compatibility with the target gas

Pressure rating of the probe or housing

Flow regulation to avoid sensor contamination

Some models, like the HENGKO HG970 series, offer custom probe materials and protective filters for specialized gas monitoring applications.

For most industrial and professional uses, dew point meters should be calibrated every 6 to 12 months, depending on usage frequency, environmental conditions, and accuracy requirements.

Regular calibration:

Ensures data reliability

Maintains regulatory compliance (e.g., ISO, GMP)

Extends the lifespan of the sensor

HENGKO and other manufacturers often offer traceable calibration services and replacement sensors for field units.

Typical high-quality portable dew point meters can measure within a range of:

-80°C to +60°C (or -112°F to +140°F)

For example, the HG970 series by HENGKO is commonly used to monitor dew point ranges from -60°C to +60°C, making it suitable for most industrial air and gas drying applications. Some lab-grade mirror hygrometers may extend lower, but portable models balance range with portability and cost-effectiveness.

Using a portable dew point meter is straightforward:

Power on the device (battery or external power).

Connect the probe to the sample point or open environment.

Allow stabilization time (usually 30 seconds to a few minutes).

Observe the real-time dew point reading on the display or via signal output.

Log or export data if required (some models offer USB or Bluetooth).

Always make sure the sensor is clean, calibrated, and not exposed to oil, dust, or corrosive chemicals.

A 露点計 is portable and often used for spot-checking or mobile diagnostics.

A 露点計 is a fixed, inline sensor installed for continuous monitoring in automated systems.

Dew point meters typically include a display and internal battery, while transmitters are integrated with PLCs or data loggers via analog (4-20mA) or digital (RS485/Modbus) output.

Yes — if it’s rated for industrial or field use. Look for:

IP-rated housing for dust and moisture protection

Stainless steel probe construction

Temperature range compatibility (e.g., -30°C to +120°C)

Shock-resistant casing

Models like the HENGKO HG970 series are designed for demanding conditions, including outdoor gas lines, drying towersあるいは factory production lines.

温度・湿度センサー、トランスミッター、ソリューションに関するお問い合わせは、HENGKOまでご連絡ください。

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more

Effective moisture management is essential in facilities where materials, equipment, and processes depend on controlled

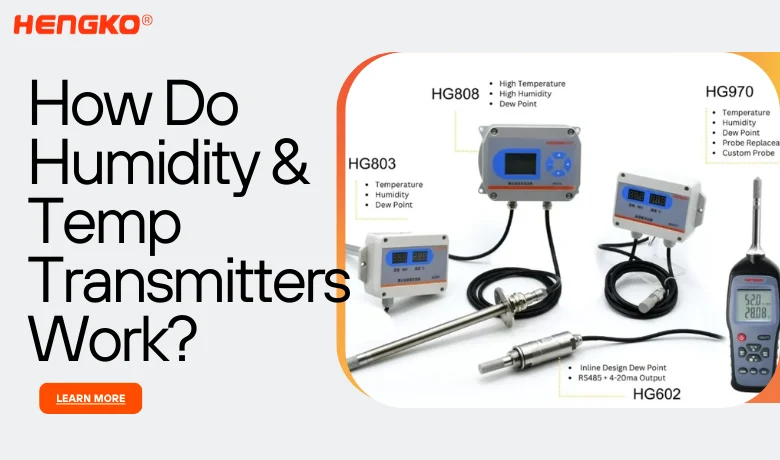

つまり、湿度・温度トランスミッターは環境データを測定し、制御システムに送信する。これらは

なぜドライヤー露点計は圧縮空気システムにとって重要なのか?もしかしたら、あなたはいつも

あるオフィスゾーンの湿度が高すぎる理由と湿度トランスミッターによる解決方法

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many

Effective moisture management is essential in facilities where materials, equipment,

WhatsAppはこちら