Batteritillverkning

Säkerställa kvalitet och effektivitet i batteritillverkningen

Hem " temperatur- och fukttransmitter för batteritillverkning

Tillverkning av litiumbatterier

Användning av fukt- och temperatursensorer vid tillverkning av litiumbatterier

Fukt- och temperatursensorer spelar en avgörande roll i olika aspekter av tillverkningen av litiumbatterier, för att säkerställa produktkvaliteten, förbättra produktionseffektiviteten och förlänga batteriets livslängd. Dessa sensorer används under hela tillverkningsprocessen, från materialberedning till montering och lagring av batterier.

Upstream-, Midstream- och Downstream-verksamhet

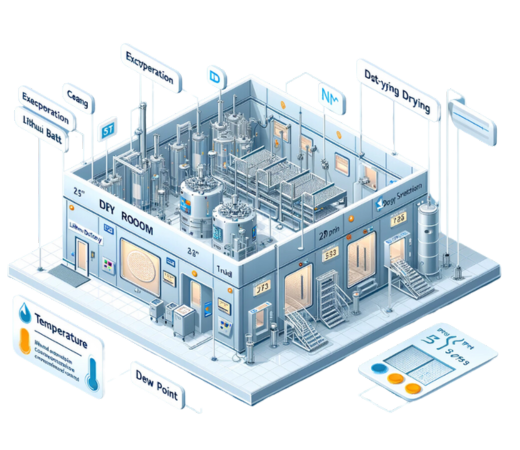

Inom midstreamverksamheten fokuserar HENGKO på att producera högkvalitativa produkter på ett mer hållbart och kostnadseffektivt sätt. Vi strävar efter att minska kostnaderna för energiintensiva arbetsuppgifter, såsom torkning och torrrumsverksamhet, som förbrukar cirka 40% av den totala energin som används under tillverkningen. Det är viktigt att skydda litium från att reagera med fukt, vilket kan leda till att det omvandlas till litiumhydroxid och väte.

Noggrann och realtidsbaserad mätningskapacitet:

- Temperatur (T)

- Daggpunkt (Td)

- Relativ luftfuktighet (RH)

- Vätskekoncentrationer (nD)

I nedströmsoperationer är det viktigt att kunna övervaka temperatur och relativ luftfuktighet på ett smidigt sätt. Vår teknik möjliggör också noggrann mätning av aggressiva kemikalier i uppströmsprocesser.

HENGKO erbjuder mätningar i världsklass med tekniskt avancerade produkter som är särskilt lämpade för ultratorra förhållanden och för kritiska processer inom fyllning och tätning.

Vad temperatur- och luftfuktighetsmätare kan göra

Säkerställa kvaliteten på batterimaterialet

Strikt kontroll av luftfuktighet och temperatur är avgörande vid beredning av litiumbatterimaterial för att bibehålla materialets renhet och konsistens. Till exempel måste luftfuktigheten ligga inom ett visst intervall vid beredning av material till positiva elektroder för att förhindra att materialet absorberar eller förlorar fukt. Sensorer för luftfuktighet och temperatur övervakar och reglerar kontinuerligt miljön i produktionsverkstaden och säkerställer att processförhållandena uppfyller de nödvändiga specifikationerna.

Ökad effektivitet i batteriproduktionen

Många processer inom litiumbatteriproduktionen har specifika krav på luftfuktighet och temperatur. Till exempel i elektrodbeläggningsprocessen måste både temperatur och luftfuktighet kontrolleras för att uppnå en jämn beläggning. Fukt- och temperatursensorer övervakar och kontrollerar dessa parametrar, vilket förbättrar produktionseffektiviteten och minskar kassationsgraden.

Förlängning av batteriets livslängd

Litiumbatteriets prestanda och livslängd påverkas av omgivande luftfuktighet och temperatur. Höga temperaturer påskyndar batteriets självurladdning, medan låga temperaturer minskar batteriets kapacitet. Sensorer för luftfuktighet och temperatur övervakar dessa parametrar under batteriets användning och möjliggör åtgärder för att förhindra överhettning eller överkylning, vilket förlänger batteriets livslängd.

Specifika applikationsexempel

Förberedelse av material för positiv elektrod: Luftfuktigheten i denna process kontrolleras mellan 30%RH och 60%RH, och temperaturen mellan 20°C och 30°C. Sensorer för luftfuktighet och temperatur övervakar och reglerar verkstadsmiljön för att uppfylla dessa specifikationer.

Elektrodbeläggning: Under elektrodbeläggningen hålls temperaturen mellan 25°C och 30°C och luftfuktigheten mellan 50%RH och 70%RH. Sensorer för luftfuktighet och temperatur övervakar och styr dessa parametrar i beläggningsverkstaden, vilket säkerställer en jämn beläggning.

Batteri montering: Temperaturen under batterimonteringen kontrolleras mellan 20°C och 25°C och luftfuktigheten mellan 40%RH och 60%RH. Sensorer för luftfuktighet och temperatur övervakar och reglerar dessa parametrar i monteringsverkstaden för att förhindra att fukt tränger in i batteriet.

Batterilagring: Under batterilagringen hålls temperaturen mellan 10°C och 20°C och luftfuktigheten mellan 30%RH och 60%RH. Sensorer för luftfuktighet och temperatur övervakar och reglerar dessa parametrar i förvaringslagret för att förhindra att batteriets prestanda försämras.

Försiktighetsåtgärder för användning

Tänk på följande när du använder fukt- och temperatursensorer vid tillverkning av litiumbatterier:

Välj lämpliga sensormodeller: Se till att mätområdet och noggrannheten uppfyller kraven.

Installera sensorerna i väl ventilerade utrymmen: Undvik värme och föroreningskällor.

Kalibrera och underhåll givarna regelbundet: Säkerställ mätnoggrannhet.

Tips

Fukt- och temperatursensorer är oumbärliga instrument vid tillverkning av litiumbatterier och spelar en viktig roll för att säkerställa batterimaterialets kvalitet, förbättra produktionseffektiviteten och förlänga batteriets livslängd. I takt med att tekniken för tillverkning av litiumbatterier utvecklas kommer fukt- och temperatursensorer att få ännu bredare användningsområden.

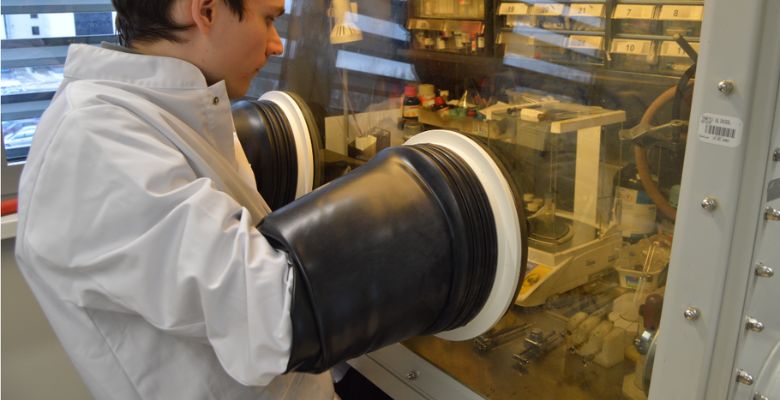

Säkra handskfacksfunktioner

Handskboxar är en viktig komponent i batteritillverkningen och erbjuder en kontrollerad, sluten och inert atmosfär som håller låga nivåer av fukt och syre. Denna miljö är avgörande för att skydda litium, elektroder och andra känsliga material från fukt och syre, vilket kan leda till nedbrytning.

HENGKO:s kompakta och integrerbara mätprober hjälper till att upprätthålla önskade låga luftfuktighetsnivåer och hålla luftfuktigheten under strikt kontroll under drift i handskfack. Detta säkerställer att elektrolyterna skyddas från nedbrytning, samtidigt som batterikomponenternas kvalitet, säkerhet och prestanda bibehålls.

Probernas direkta installation i handskfacket, tillsammans med deras kemikalietolerans och snabba reaktionstid, möjliggör extremt snabb sekvensstyrning, vilket ökar effektiviteten i verksamheten.

Sammanfatta

Strategier för kontroll av luftfuktighet och temperatur

För att upprätthålla önskad luftfuktighet och temperatur i säkerhetshandskboxen används ofta följande strategier:

Använda sensorer för luftfuktighet och temperatur: Dessa sensorer övervakar kontinuerligt handskboxens inre luftfuktighet och temperatur.

Använda luftkonditioneringsapparater eller avfuktare: Luftkonditioneringsapparater reglerar temperaturen, medan avfuktare reglerar luftfuktigheten.

Regelbunden inspektion och underhåll: Inspektera och underhåll regelbundet fukt- och temperaturgivare, luftkonditioneringsapparater och avfuktare för att säkerställa korrekt drift.

Specifika applikationsexempel

Materialförberedelse: Håll handskboxens temperatur mellan 20°C och 30°C och luftfuktigheten mellan 30%RH och 60%RH under materialberedningen.

Elektrodbeläggning: Kontrollera handskboxens temperatur mellan 25°C och 30°C och luftfuktigheten mellan 50%RH och 70%RH under elektrodbestrykningen.

Relaterade produkter

HITTA RÄTT TRANSMITTER FÖR TEMPERATUR OCH LUFTFUKTIGHET

Berätta om ditt projekt för oss idag

Berätta för oss om ditt Monitor-projekt,

Vi kommer att ge dig den bästa lösningen till konkurrenskraftiga priser inom 3 dagar.

Vi kommer att ge dig den bästa lösningen till konkurrenskraftiga priser inom 3 dagar.

Sprid världen

HENGKO är en global ledare inom industriella sensorlösningar, med ett rykte om unik design och utmärkt prestanda. Våra temperatur- och luftfuktighetstransmittrar och sensorer används i ett brett spektrum av industrier, inklusive livsmedel och drycker, läkemedel, tillverkning och miljöövervakning.

0

+

Antal års erfarenhet

0

Försäljning över hela världen

0

K

Industriella projekt

Andra populära projekt

Vinkällare

Fulländad konservering: Hantering av temperatur och luftfuktighet för vinlagring

Sjukhus och laboratorier

Precision inom sjukvården: Säkerställa sterila och stabila miljöer

Jordbrukslager

Optimering av lagring av grödor: Stabilisering av förhållanden efter skörd