In air separation nitrogen generation systems, high-purity gas output depends on more than just core components like compressors, dryers, and PSA towers. One often-overlooked factor can quietly erode system efficiency, gas purity, and equipment lifespan: environmental instability.

From excessive humidity at the intake to fluctuating temperatures during adsorption, environmental conditions affect every stage of nitrogen production. That’s where temperature and humidity monitoring becomes a powerful enabler—not just for protection, but for performance optimization.

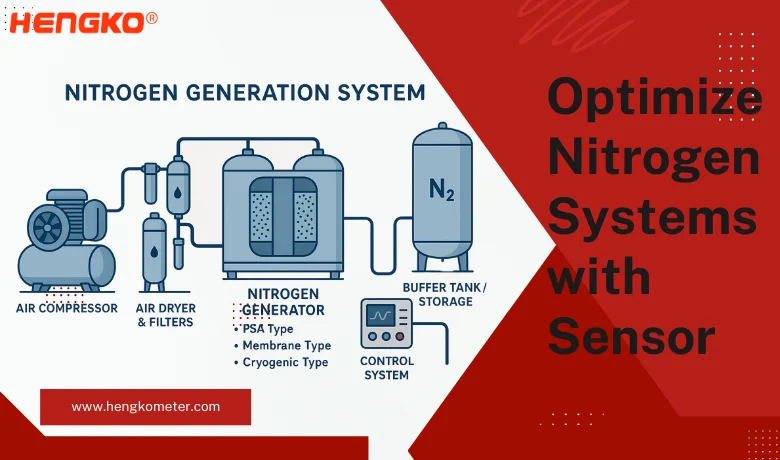

What is the Nitrogen Generation System?

A Nitrogen Generation System is an industrial setup that produces high-purity nitrogen gas from ambient air, typically using methods such as Pressure Swing Adsorption (PSA), Membrane Separation, or Cryogenic Air Separation. These systems are used across various industries like food packaging, electronics, pharmaceuticals, chemicals, and metallurgy, where a consistent and on-demand nitrogen supply is essential.

Key Components:

·Air Compressor – Draws in and compresses ambient air.

·Air Dryer & Filters – Removes moisture, oil, and particulates.

·Nitrogen Generator Unit – Separates nitrogen from other gases:

·PSA Type: Uses carbon molecular sieves to adsorb oxygen.

·Membrane Type: Uses polymer membranes to separate gases.

·Cryogenic Type: Cools air to extremely low temperatures to isolate nitrogen.

·Buffer Tank/Storage – Stores the generated nitrogen for use.

·Control System – Manages flow, pressure, and purity.

How a Nitrogen Generation System Works

1. Air Intake and Compression

Ambient air (78% nitrogen, 21% oxygen, and traces of other gases) is drawn in.

An air compressor pressurizes this air to the required operating pressure (typically 6–10 bar).

2. Pre-Treatment (Drying and Filtration)

The compressed air passes through filters and a dryer to remove:

·Water vapor (humidity)

·Oil particles

·Dust and other contaminants

This step is crucial to protect the sensitive components in later stages.

3. Nitrogen Separation – PSA Process

The clean, dry compressed air enters two towers filled with Carbon Molecular Sieve (CMS).

Here’s what happens:

·CMS adsorbs oxygen molecules due to their smaller size and higher affinity.

·Nitrogen molecules pass through as they are not adsorbed.

·While one tower is producing nitrogen, the other is regenerating (releasing adsorbed oxygen by depressurizing).

The system alternates between the towers every 30–90 seconds to provide a continuous nitrogen flow.

4. Buffer Tank / Storage

The nitrogen gas flows into a buffer/storage tank to:

·Stabilize pressure

·Store nitrogen for peak demand

·Further purify and dry the gas (optional)

5. Delivery and Use

The nitrogen is delivered directly to the point of use or piped into a centralized distribution system for various applications.

Why Temperature and Humidity Monitoring Matters

While the nitrogen generation process may seem straightforward, its stability and efficiency heavily depend on environmental conditions—especially temperature and humidity. Even slight fluctuations can lead to equipment wear, gas purity issues, or production delays.

| Stage | Environmental Risk | Consequences |

| Compressor Room | High ambient temperature and humidity | Reduced efficiency, overheating |

| Pre-treatment (before dryer) | Moisture in intake air | Adsorbent degradation, low drying efficiency |

| PSA Unit (adsorption tower) | Temperature fluctuation | Impacts adsorption balance, purity loss |

| Gas Output & Storage | Re-condensation of water vapor | Pipeline corrosion, gas contamination |

| End-Use Environment | Uncontrolled ambient conditions | Product defects, unstable production |

These problems may be silent—but they’re certainly not harmless.

Strategic Monitoring: Deploying Sensors Where They Matter Most

To combat these risks, temperature and humidity sensors should be strategically installed at critical control points throughout the nitrogen system. Here’s how:

●Compressor Room Monitoring

Wall-mounted temperature and humidity transmitters help monitor environmental conditions around compressors. If the ambient temperature or humidity rises, the system can automatically trigger ventilation or alarms—preventing overheating and improving energy efficiency.

●Pre-Treatment Moisture Control

Humidity and dew point sensors play a critical role before the air enters the dryer unit. High inlet humidity shortens the dryer’s lifespan and leads to water carryover into downstream processes. Inline humidity transmitters help operators detect excessive moisture and respond before damage occurs.

●PSA Unit Stability Monitoring

Adsorption performance is highly sensitive to temperature. If the adsorbent is exposed to thermal fluctuation, nitrogen purity can drop and regeneration cycles become inefficient. Probe-type temperature sensors inside the PSA chamber provide real-time thermal feedback to keep the process optimized.

●Output Line Quality Assurance

Even after successful nitrogen generation, humidity remains a threat. Water vapor can re-condense in output lines or buffer tanks. Using dew point transmitters at the gas output ensures that only dry nitrogen reaches the customer.

●End-Use Environmental Control

In industries like electronics, food, or pharmaceuticals, nitrogen is not only a product—it’s part of a tightly controlled environment. Installing temperature and humidity monitoring in production or packaging zones ensures full-chain environmental compliance and product quality.

Case Study: How HENGKO Improved Gas Purity and Reduced Downtime

When a leading nitrogen generator manufacturer was facing frequent production interruptions and gas purity issues, they turned to HENGKO for a smarter solution. The root of the problem? Unstable dew point levels in their air separation drying system were causing premature adsorbent degradation and frequent shutdowns for maintenance.

To address this, the manufacturer integrated HENGKO’s HG808-D Dew Point Transmitter, capable of accurately monitoring dew point down to -40°C (Td) in real time. Positioned directly within the drying system, the HG808-D delivered continuous, high-precision measurements that enabled the operator to:

·Detect moisture spikes instantly

·Optimize regeneration timing

·Prevent unnecessary wear on the CMS towers

Results That Speak Volumes:

✅ Gas purity compliance surged to 99.9%, eliminating out-of-spec batches and rework

✅ Equipment failure rate dropped by 40%, thanks to better moisture control and predictive maintenance

✅ Operational efficiency increased, with less downtime and extended adsorbent life

What’s more, the maintenance team reported fewer emergency interventions and improved system stability across the entire production line.

“Before installing the HG808-D, we were chasing problems we couldn’t see. Now we see everything in real-time—and solve issues before they happen.”

— Maintenance Supervisor, Nitrogen Equipment Manufacture

Precision Monitoring for Every Stage of Your Nitrogen System

— Tailored Solutions from HENGKO

Ensure optimal performance and regulatory compliance across your entire nitrogen generation and distribution process. HENGKO provides a comprehensive portfolio of temperature, humidity, and dew point transmitters, each engineered for specific control points:

·Compressor Room – Wall-mounted transmitters for ambient condition regulation and early-warning triggers

·Pre-Treatment Stage – Inline humidity sensors to prevent dryer overload and moisture breakthrough

·PSA Unit – High-accuracy probes for real-time thermal feedback and adsorption efficiency

·Output Lines – Dew point transmitters for ensuring gas dryness and downstream integrity

·End-Use Areas – Environmental monitors for cleanroom-level control in critical industries

One system. Multiple needs. One expert partner.

Contact HENGKO at sales@hengko.meter.com today to select the optimal sensor configuration for your application.

Slutsats

In the world of nitrogen generation, small environmental changes can cause big disruptions. Strategic deployment of temperature, humidity, and dew point sensors can safeguard every stage of the process—from air intake to nitrogen delivery.

Whether you’re building new systems or optimizing existing lines, choosing the right environmental monitoring solutions ensures consistent gas purity, reduces equipment wear, and lowers operational costs.