In the paper manufacturing industry, environmental control is not just a technical detail—it’s a critical quality factor. Paper, by nature, is a hygroscopic material. This means it absorbs and releases moisture depending on the surrounding air conditions. Without consistent temperature and humidity control, paper can become warped, brittle, or even moldy—leading to costly waste, product returns, and damaged brand reputation.

From the heat and vapor of the pulping area to the quiet storage rooms of finished rolls, every stage of production presents its own environmental challenges. To maintain product quality and process stability, manufacturers are turning to intelligent monitoring systems.

Environmental Challenges Across the Paper Process

1. Pulping Area – High Moisture, Chemical Vapors

Environmental Characteristics:

• Relative Humidity (RH): Often exceeds 90%

• Temperature: Elevated due to steam and chemical reactions

• Risk Factors: Acidic gases, high humidity, corrosion

Why Monitoring Matters:

In pulping, wood chips are broken down into fiber using heat, water, and chemicals. Without proper environmental control, excess humidity promotes microbial growth and uneven moisture distribution in pulp, affecting fiber consistency and increasing drying loads in the next stage.

Monitoring Strategy:

Install humidity transmitters resistant to corrosion and high RH to track conditions and trigger ventilation systems, ensuring a controlled atmosphere for consistent pulp quality.

2. Pressing Section – Mechanical Stress & Condensation Risk

Environmental Characteristics:

• RH: 80–95%

• Risk Factors: Condensation on equipment, fluctuating pressure, high-speed mechanical processes

Why Monitoring Matters:

Pressing removes water from pulp through pressure and heat. Humidity must be closely managed to avoid condensation, which can damage machinery and re-wet partially dried pulp.

Monitoring Strategy:

Användning fast-response sensors with anti-condensation features to detect microclimate shifts and adjust dehumidification systems instantly.

3. Drying Section – Heat Cycles and Moisture Precision

Environmental Characteristics:

• Temperature: High (up to 120°C)

• RH: Rapidly decreasing across dryer sections

• Risk Factors: Thermal drift, sensor degradation, uneven drying

Why Monitoring Matters:

Drying consumes a significant portion of energy in paper production. Overdrying can lead to brittle paper and energy waste; underdrying results in curl or poor surface properties. Real-time monitoring helps fine-tune the heat and air balance for optimal results.

Monitoring Strategy:

Deploy high-temperature-resistant sensors capable of maintaining accuracy during thermal cycling. Integrate with drying control systems for energy-efficient regulation.

4. Finishing and Reeling – Dimensional Stability at Risk

Environmental Characteristics:

• RH: Should stabilize between 45–55%

• Risk Factors: Curling, static electricity, coating issues

Why Monitoring Matters:

In finishing steps like calendaring, coating, and reeling, paper is extremely sensitive to ambient RH. Uncontrolled humidity leads to expansion or shrinkage, directly impacting roll uniformity and printability.

Monitoring Strategy:

Maintain stable RH across finishing lines using precision transmitters and localized control systems. This ensures smooth operation of downstream processes and prevents defects.

5. Storage and Warehousing – Long-Term Stability

Environmental Characteristics:

• Target RH: 50–55%

• Risk Factors: Moisture absorption, mold, edge curling, strength loss

Why Monitoring Matters:

Paper continues to interact with its environment after production. Improper storage can degrade days or weeks of effort. Ensuring consistent RH and temperature in storage is essential for preserving quality and meeting customer expectations.

Monitoring Strategy:

Install multiple distributed sensors throughout storage zones, connected to centralized HVAC or dehumidification systems. Use long-term logging for traceability and audits.

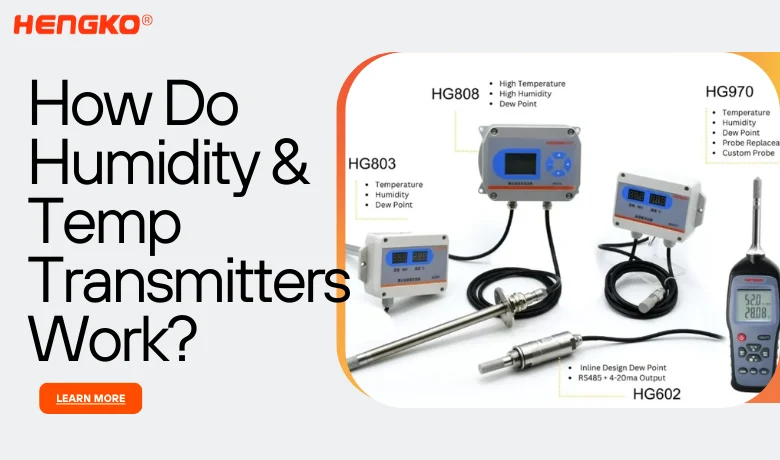

The Role of Industrial Temperature and Humidity Transmitters

To maintain optimal conditions throughout the paper production line, continuous and accurate environmental monitoring is essential. Industrial temperature and humidity transmitters act as the “eyes and ears” of the factory environment, enabling real-time data collection, analysis, and response.

Unlike basic sensors, industrial-grade transmitters are designed for harsh production conditions—high humidity, chemical vapors, steam, and frequent temperature fluctuations. Their robust construction and high precision allow them to deliver stable performance where standard equipment often fails.

The most important thing you should know is the final know By installing transmitters at critical control points—such as pulp preparation tanks, drying tunnels, finishing lines, and storage zones—manufacturers gain the ability to:

✅ Detect environmental deviations before they impact quality

✅ Automatically adjust ventilation or dehumidification systems

✅ Optimize energy usage during drying processes

✅ Ensure consistency in final product dimensions and strength

✅ Generate historical data for quality audits and process improvement

Ultimately, temperature and humidity transmitters are not just passive measurement tools—they are integral to intelligent process control and long-term quality assurance in paper manufacturing.

Why HG808-H Excels in Harsh Paper Environments

Given the demanding environmental conditions found across the entire paper production cycle—from high-humidity pulp areas to heat-intensive drying zones—choosing the right transmitter is critical. Not all sensors are built to withstand such extremes while maintaining long-term accuracy and stability. This is where specialized solutions – HG808 H come into play.

HG808-H transmitter isn’t a general-purpose sensor—it’s engineered specifically for extreme industrial conditions:

·Dual-layer protection with a die-cast aluminum body and a stainless-steel sensor module resists corrosion, moisture, oil mist, and dust.

·Maintains ±2% RH accuracy in environments with up to 95% relative humidity.

·Long-term drift is minimal, reducing calibration frequency and maintenance costs.

·Resistant to chemical interference and mechanical shock.

·Fully compatible with PLC, DCS, and building automation systems via Modbus/RS485 or 4–20 mA output.

·Performs in pulping, pressing, drying, and storage—one sensor for all stages.

HG808-H also utilizes advanced composite sensing technology to shield against vapor and interference, ensuring accurate readings even in the most chaotic industrial environments.

FAQ: Choosing and Using a Humidity Transmitter in Paper Production

Q1: What humidity range should I monitor in different paper production stages?

A1: Humidity varies significantly across the process:

Pulping: >90% RH

Pressing: 80–95% RH

Drying: Rapidly decreasing RH, often to <10%

Finishing: 45–55% RH

Storage: 50–55% RH

Sensors must be accurate and stable across these ranges, especially under fast-changing conditions.

Q2: Can one type of transmitter cover all stages?

A2: Only industrial-grade transmitters like HG808-H are designed to operate accurately across all these

conditions—from high-humidity pulp areas to high-temperature drying zones—minimizing the need for multiple sensor types.

Q3: How often should I calibrate the sensor?

A3: For typical paper environments, annual calibration is recommended.

However, in harsh zones with chemical vapors or thermal cycling, semi-annual checks are advisable.

HG808-H is engineered to minimize drift and extend calibration intervals.

Q4: How should I position the transmitters for accurate readings?

A4: Avoid placement directly in airflow from vents or fans.

Mount at representative height (typically 1.5–2m from ground).

Use protective filters or housings in areas exposed to mist or dust.

Distribute sensors across key points for multi-zone control.

Slutsats

Environmental instability is a hidden risk that can cost manufacturers dearly. Poor humidity control leads to irreversible

damage in paper strength, appearance, and usability.

But with the HG808-H, these risks are eliminated—thanks to its industrial durability, real-time responsiveness,

and precision even in the toughest conditions.

Whether you’re battling steam in the pulping room, controlling RH in a multi-zone warehouse, or facing thermal

shock in the drying tunnel, HG808-H is your reliable front-line defense.