Μέτρηση σημείου δρόσου: Ο ακρογωνιαίος λίθος της καθαρότητας του πεπιεσμένου αέρα.

Η ποιότητα του πεπιεσμένου αέρα συχνά παραβλέπεται, ωστόσο αποτελεί κρίσιμο παράγοντα για την αποδοτικότητα και την αξιοπιστία αμέτρητων βιομηχανικών διεργασιών. Η υγρασία, ένας κοινός ρύπος, μπορεί να προκαλέσει καταστροφές στον εξοπλισμό, να μειώσει την απόδοση της παραγωγής και να θέσει σε κίνδυνο την ποιότητα των προϊόντων. Εδώ είναι που μπαίνει στο παιχνίδι η μέτρηση του σημείου δρόσου. Με τον ακριβή προσδιορισμό της θερμοκρασίας στην οποία συμπυκνώνονται οι υδρατμοί, η μέτρηση του σημείου δρόσου παρέχει ανεκτίμητες πληροφορίες για την ποιότητα του πεπιεσμένου αέρα.

Σε αυτόν τον οδηγό, θα εμβαθύνουμε στον κόσμο των συσκευών μέτρησης σημείου δρόσου, βοηθώντας σας να επιλέξετε το τέλειο εργαλείο για τη διασφάλιση του συστήματος πεπιεσμένου αέρα και τη βελτιστοποίηση των λειτουργιών σας.

Κατανόηση του σημείου δρόσου σε συστήματα πεπιεσμένου αέρα

Τι είναι το σημείο δρόσου;

Σημείο δρόσου είναι η θερμοκρασία στην οποία ο αέρας γίνεται κορεσμένος με υδρατμούς και αρχίζει να συμπυκνώνεται σε υγρό νερό.

Στο πλαίσιο των συστημάτων πεπιεσμένου αέρα, είναι η θερμοκρασία στην οποία οι υδρατμοί του πεπιεσμένου αέρα συμπυκνώνονται σε υγρή μορφή.

www.processsensing.com

www.generon.com

Ο αντίκτυπος του σημείου δρόσου στην ποιότητα του πεπιεσμένου αέρα

Η υγρασία στον πεπιεσμένο αέρα μπορεί να επηρεάσει αρνητικά την απόδοση, την ασφάλεια και την αποδοτικότητα του συστήματος. Ακούστε πώς:

www.atlascopco.com

- Βλάβη εξοπλισμού: Το υγρό νερό μπορεί να προκαλέσει σοβαρές ζημιές σε πνευματικά εργαλεία, βαλβίδες, κυλίνδρους και άλλα εξαρτήματα. Η διάβρωση, η διάβρωση και το υδραυλικό κλείδωμα είναι κοινά προβλήματα.1. Καταπολέμηση του δολοφόνου των βιομηχανικών πνευματικών συστημάτων - Νερό - Τεχνικά άρθρα

control.com

- Μόλυνση προϊόντος: Η υγρασία μπορεί να μολύνει τα προϊόντα, ειδικά σε βιομηχανίες όπως η φαρμακευτική, η επεξεργασία τροφίμων και η ηλεκτρονική.

- Μειωμένη απόδοση: Οι υδρατμοί αυξάνουν τον όγκο του πεπιεσμένου αέρα, μειώνοντας την απόδοση του συμπιεστή και αυξάνοντας την κατανάλωση ενέργειας.

- Ζητήματα απόδοσης συστήματος: Η υγρασία μπορεί να προκαλέσει παγοποίηση στα πνευματικά συστήματα, οδηγώντας σε δυσλειτουργίες και διακοπή λειτουργίας.1. Παγοποίηση κινητήρα αέρα - Έχετε πρόβλημα παγοποίησης; - Graco Inc.

www.graco.com

- Κίνδυνοι για την ασφάλεια: Σε ορισμένες εφαρμογές, η υγρασία μπορεί να δημιουργήσει επικίνδυνες συνθήκες, όπως στη συγκόλληση ή στη βαφή με ψεκασμό.

Με την ακριβή μέτρηση του σημείου δρόσου, μπορείτε να εντοπίσετε πιθανά προβλήματα και να λάβετε διορθωτικά μέτρα για την προστασία του εξοπλισμού, των προϊόντων και του προσωπικού σας.

Βασικές εκτιμήσεις για την επιλογή μιας συσκευής σημείου δρόσου για πεπιεσμένο αέρα

Ακρίβεια και εύρος μέτρησης

Επεξήγηση: Η ακρίβεια στις μετρήσεις του σημείου δρόσου είναι ζωτικής σημασίας για τη διατήρηση της βέλτιστης ποιότητας του αέρα στα συστήματα πεπιεσμένου αέρα.Απαιτήσεις εύρους: Διαφορετικές εφαρμογές έχουν διαφορετικές ανάγκες σε σημεία δρόσου, όπως συστήματα εξαιρετικά ξηρού αέρα σε σχέση με περιβάλλοντα με υψηλότερα επίπεδα υγρασίας.

Χρόνος απόκρισης

Επεξήγηση: Ο γρήγορος χρόνος απόκρισης είναι απαραίτητος για την παρακολούθηση σε πραγματικό χρόνο και την έγκαιρη προσαρμογή του συστήματος.Παραδείγματα εφαρμογής: Οι γρήγοροι χρόνοι απόκρισης μπορούν να αποτρέψουν αποτυχίες του συστήματος ή προβλήματα ποιότητας σε σενάρια όπου απαιτείται άμεση δράση.

Τεχνολογία μέτρησης

Τύποι: Οι συνήθεις τεχνολογίες περιλαμβάνουν χωρητικές, ψυχρού κατόπτρου και οπτικές μεθόδους μέτρησης.Καταλληλότητα για πεπιεσμένο αέρα: Κάθε τεχνολογία έχει τα πλεονεκτήματα και τα μειονεκτήματά της όσον αφορά τη δοκιμή της ποιότητας του πεπιεσμένου αέρα. Για παράδειγμα, οι χωρητικοί αισθητήρες είναι γενικά πιο ανθεκτικοί, ενώ οι συσκευές ψυχρού καθρέφτη προσφέρουν υψηλή ακρίβεια.

Ευκολία ενσωμάτωσης

Συμβατότητα: Διασφαλίστε ότι η συσκευή σημείου δρόσου μπορεί να ενσωματωθεί απρόσκοπτα στα υπάρχοντα συστήματα πεπιεσμένου αέρα.Απαιτήσεις εγκατάστασης: Εξετάστε παράγοντες που συμβάλλουν στην απροβλημάτιστη εγκατάσταση και λειτουργία, όπως το μέγεθος της συσκευής, οι απαιτήσεις ισχύος και οι επιλογές συνδεσιμότητας.

Βαθμονόμηση και συντήρηση

Ανάγκες βαθμονόμησης: Η τακτική βαθμονόμηση είναι απαραίτητη για τη διατήρηση της ακρίβειας της συσκευής. Αξιολογήστε τη συχνότητα και την ευκολία της βαθμονόμησης.Απαιτήσεις συντήρησης: Οι τυπικές εργασίες συντήρησης θα πρέπει να αξιολογούνται ως προς τον αντίκτυπό τους στην απόδοση της συσκευής και τη συνολική αποδοτικότητα του συστήματος.

Τύποι συσκευών σημείου δρόσου για συστήματα πεπιεσμένου αέρα

Φορητοί μετρητές σημείου δρόσου

Περιγραφή:

Οι φορητοί μετρητές σημείου δρόσου είναι φορητές συσκευές σχεδιασμένες για επιτόπιες μετρήσεις και προσωρινές ρυθμίσεις. Συνήθως διαθέτουν:

- Συμπαγής, ελαφρύς σχεδιασμός

- Λειτουργία με μπαταρία

- Ψηφιακές οθόνες για εύκολη ανάγνωση

- Εξαρτήματα ταχείας σύνδεσης για διάφορα σημεία δειγματοληψίας

- Δυνατότητες καταγραφής δεδομένων

Ιδανικές περιπτώσεις χρήσης:

- Δειγματοληπτικοί έλεγχοι σε πολλές τοποθεσίες

- Αντιμετώπιση προβλημάτων υγρασίας

- Επαλήθευση των ενδείξεων του σταθερού συστήματος

- Προσωρινή παρακολούθηση κατά τη διάρκεια συντήρησης ή αλλαγών στο σύστημα

Οφέλη:

- Ευελιξία για τη μέτρηση του σημείου δρόσου σε διαφορετικές θέσεις

- Εύκολη μεταφορά μεταξύ εγκαταστάσεων ή σημείων μέτρησης

- Επιτρέπει γρήγορες αξιολογήσεις χωρίς μόνιμη εγκατάσταση

- Χρήσιμο για περιοδικούς ελέγχους και ελέγχους ποιότητας

Σταθεροί πομποί σημείου δρόσου

Περιγραφή:

Οι σταθεροί πομποί σημείου δρόσου είναι μόνιμα εγκατεστημένες συσκευές για συνεχή παρακολούθηση. Τα βασικά χαρακτηριστικά περιλαμβάνουν:

- Στιβαρή κατασκευή για μακροχρόνια βιομηχανική χρήση

- Διάφορες επιλογές εξόδου (π.χ. 4-20mA, Modbus)

- Δυνατότητες συναγερμού για την υπέρβαση των καθορισμένων ορίων

- Επιλογές για πιστοποιήσεις επικίνδυνων περιοχών

- Ορισμένα μοντέλα περιλαμβάνουν τοπικές οθόνες και χειριστήρια

Ιδανικές περιπτώσεις χρήσης:

- Συνεχής παρακολούθηση των κρίσιμων διεργασιών

- Ενσωμάτωση με συστήματα διαχείρισης κτιρίων ή SCADA

- Μακροπρόθεσμη ανάλυση τάσεων της ποιότητας του αέρα

- Αυτοματοποιημένος έλεγχος του εξοπλισμού επεξεργασίας αέρα

Οφέλη:

- Παρέχει συνεχή δεδομένα σε πραγματικό χρόνο για την ποιότητα του αέρα

- Επιτρέπει την προληπτική συντήρηση και την έγκαιρη ανίχνευση προβλημάτων

- Υποστηρίζει αυτοματοποιημένα συστήματα ελέγχου για βελτιστοποιημένη επεξεργασία αέρα

- Επιτρέπει τη μακροπρόθεσμη καταγραφή και ανάλυση δεδομένων

- Μπορεί να ενσωματωθεί με άλλες παραμέτρους ελέγχου της διεργασίας για ολοκληρωμένη διαχείριση του συστήματος

Και οι δύο τύποι συσκευών διαδραματίζουν κρίσιμο ρόλο στη διατήρηση της ποιότητας του πεπιεσμένου αέρα, ενώ η επιλογή εξαρτάται από τις συγκεκριμένες ανάγκες της εφαρμογής, τη συχνότητα παρακολούθησης και τις απαιτήσεις ολοκλήρωσης του συστήματος.

Προϋπολογισμός και επενδύσεις

Ανάλυση κόστους έναντι οφέλους

Εξισορρόπηση του αρχικού κόστους με τα οφέλη: Η επένδυση σε συσκευές μέτρησης σημείου δρόσου συνεπάγεται αρχικό κόστος, αλλά τα οφέλη συχνά υπερκαλύπτουν αυτά τα αρχικά έξοδα. Η ακριβής μέτρηση του σημείου δρόσου εξασφαλίζει τη βέλτιστη απόδοση και αποδοτικότητα των συστημάτων πεπιεσμένου αέρα, γεγονός που μπορεί να οδηγήσει σε σημαντική εξοικονόμηση κόστους με την πάροδο του χρόνου. Τα βασικά οφέλη περιλαμβάνουν:- Πρόληψη ζημιών στον εξοπλισμό: Αποφεύγοντας προβλήματα που σχετίζονται με την υγρασία, όπως η διάβρωση και η υδραυλική ασφάλιση, οι επιχειρήσεις μπορούν να μειώσουν το κόστος επισκευής και αντικατάστασης.

- Διατήρηση της ποιότητας του προϊόντος: Η εξασφάλιση ξηρού αέρα αποτρέπει τη μόλυνση, η οποία είναι ζωτικής σημασίας σε βιομηχανίες όπως η φαρμακευτική βιομηχανία και η επεξεργασία τροφίμων.

- Βελτίωση της αποδοτικότητας: Η ακριβής μέτρηση του σημείου δρόσου συμβάλλει στη διατήρηση της απόδοσης του συμπιεστή, μειώνοντας την κατανάλωση ενέργειας και το λειτουργικό κόστος.

Μακροπρόθεσμη αξία

Σκέψεις για μακροπρόθεσμη αξιοπιστία και εξοικονόμηση κόστους: Η επένδυση σε συσκευές μέτρησης σημείου δρόσου υψηλής ποιότητας μπορεί να προσφέρει σημαντική μακροπρόθεσμη αξία μέσω:- Ενισχυμένη αξιοπιστία του συστήματος: Η συνεχής παρακολούθηση βοηθά στον εντοπισμό και την αντιμετώπιση προβλημάτων υγρασίας πριν προκαλέσουν σημαντική ζημιά ή χρόνο διακοπής λειτουργίας.

- Εξοικονόμηση ενέργειας: Ο αποτελεσματικός έλεγχος της υγρασίας μπορεί να οδηγήσει σε χαμηλότερο ενεργειακό κόστος. Για παράδειγμα, η εναλλαγή που εξαρτάται από το σημείο δρόσου (DDS) στους ξηραντήρες με ξηραντικό μπορεί να εξοικονομήσει έως και 80% στο ενεργειακό κόστος, κάνοντας την επένδυση να αποσβεστεί μέσα σε ένα χρόνο.

- Μειωμένος χρόνος διακοπής λειτουργίας: Η προληπτική συντήρηση που επιτρέπει η ακριβής παρακολούθηση του σημείου δρόσου ελαχιστοποιεί τις απροσδόκητες βλάβες του συστήματος, εξασφαλίζοντας αδιάλειπτη λειτουργία.

- Συμμόρφωση και διασφάλιση ποιότητας: Η διατήρηση των απαιτούμενων επιπέδων σημείου δρόσου διασφαλίζει τη συμμόρφωση με τα βιομηχανικά πρότυπα (π.χ. ISO8573.1) και βελτιώνει την ποιότητα των προϊόντων, μειώνοντας τα απόβλητα και την επανεπεξεργασία.

Αξιολόγηση προμηθευτών και προϊόντων

Αξιόπιστες μάρκες

Αρκετοί κορυφαίοι κατασκευαστές είναι γνωστοί για τις υψηλής ποιότητας συσκευές μέτρησης σημείου δρόσου:

- Vaisala: Φημίζεται για την προηγμένη τεχνολογία αισθητήρων και τα αξιόπιστα όργανα.

- Ελκόμετρο: Προσφέρει ανθεκτικούς μετρητές σημείου δρόσου σχεδιασμένους για σκληρά βιομηχανικά περιβάλλοντα.

- Alpha Moisture Systems: Ειδικεύεται στα όργανα μέτρησης σημείου δρόσου για βιομηχανικά αέρια και μέτρηση υγρασίας σε ίχνη.

- Senseca: Παρέχει μια σειρά λύσεων μέτρησης σημείου δρόσου για διάφορες εφαρμογές.

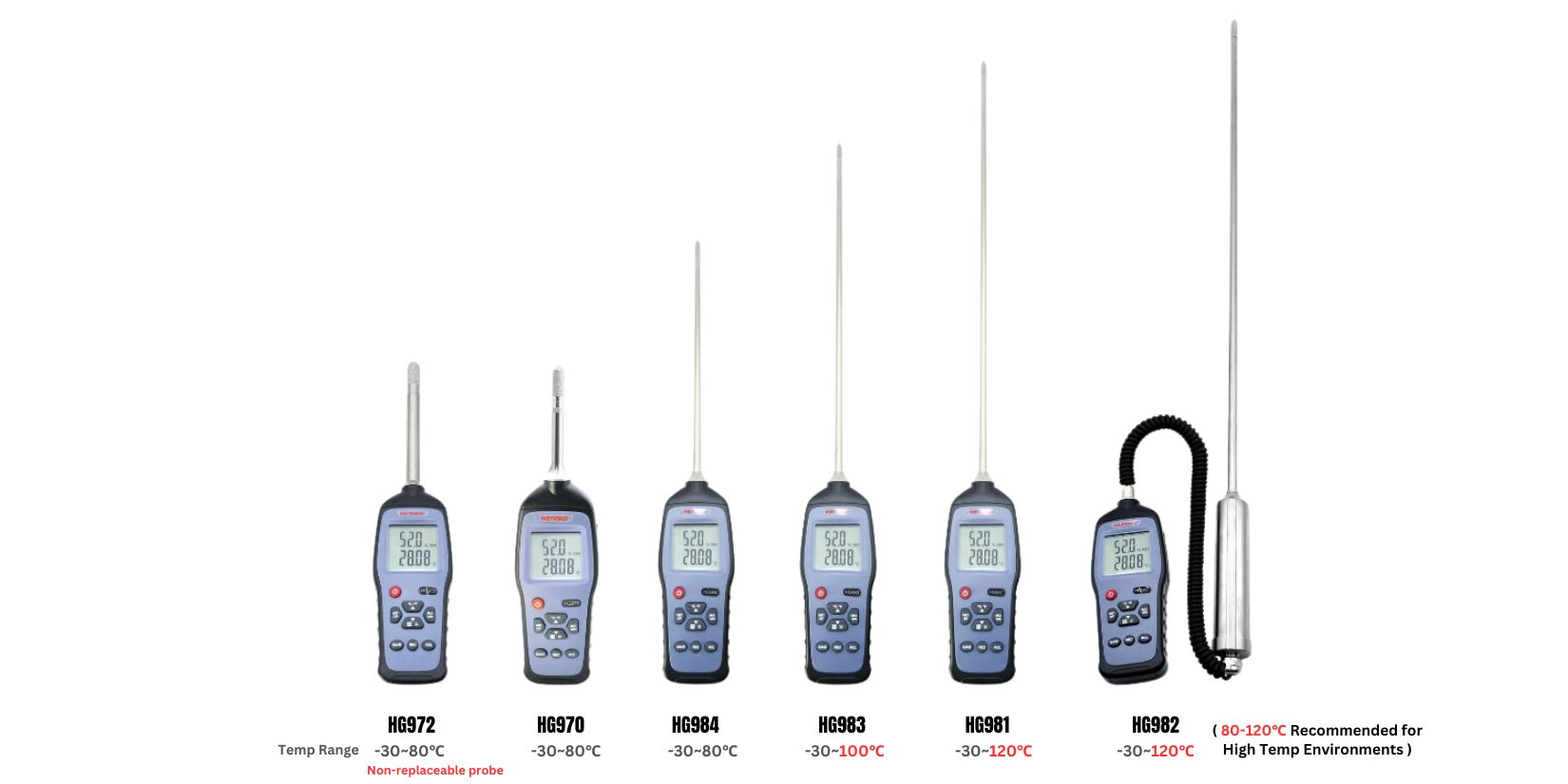

- HENGKO: Προμήθεια ειδών αισθητήρα σημείου δρόσου, συμπεριλαμβανομένου πομπού φορητός μετρητής σημείου δρόσου, πομπός σημείου δρόσου επιτοίχιας τοποθέτησης για δοκιμές στο σύστημα πίεσης αέρα.

Άλλες αξιοσημείωτες μάρκες περιλαμβάνουν τις MICHELL INSTRUMENTS, CS Instruments και Testo.

Συμπέρασμα

Η επιλογή της κατάλληλης συσκευής μέτρησης σημείου δρόσου είναι ζωτικής σημασίας για τη διατήρηση και τη βελτίωση της ποιότητας του πεπιεσμένου αέρα. Η σωστή συσκευή μπορεί:

- Εξασφαλίστε σταθερή ποιότητα αέρα σε όλο το σύστημά σας

- Πρόληψη ζημιών στον εξοπλισμό που σχετίζονται με την υγρασία και μόλυνση του προϊόντος

- Βελτιστοποίηση της ενεργειακής απόδοσης και μείωση του λειτουργικού κόστους

- Διευκόλυνση της συμμόρφωσης με τα πρότυπα και τους κανονισμούς του κλάδου

- Ενεργοποιήστε την προληπτική συντήρηση και ελαχιστοποιήστε τον απροσδόκητο χρόνο διακοπής λειτουργίας

Η διαδικασία επιλογής περιλαμβάνει προσεκτική εξέταση παραγόντων όπως η ακρίβεια, το εύρος μέτρησης, ο χρόνος απόκρισης και οι δυνατότητες ενσωμάτωσης. Επιπλέον, η κατανόηση των διαφόρων τύπων διαθέσιμων συσκευών και της καταλληλότητάς τους για συγκεκριμένες εφαρμογές είναι απαραίτητη για τη λήψη τεκμηριωμένης απόφασης.

Επιλέγοντας προσεκτικά τη σωστή συσκευή σημείου δρόσου, μπορείτε να βελτιώσετε σημαντικά την απόδοση, την αποδοτικότητα και την αξιοπιστία του συστήματος πεπιεσμένου αέρα που διαθέτετε. Η επένδυση αυτή θα συμβάλει στη βελτίωση της ποιότητας των προϊόντων, στη μείωση του λειτουργικού κόστους και στην αύξηση της συνολικής αποτελεσματικότητας του συστήματος.