Dew Point Sensor for Compressed Air

高度な露点監視でエアシステムを最適化

ホーム " Dew Point Sensor for Compressed Air

Dew Point Sensor for Compressed Air Various Solution Supplier

Diverse Dew Point Solutions for Comprehensive Air System Management

HENGKO stands at the forefront of innovation as a leading supplier of dew point sensors for compressed air systems.

We offer a diverse range of solutions tailored to meet the international ISO 8573-1 standard for compressed air quality, compressed air needs to be dried and filtered to remove excess moisture and particulates.. Our dew point sensors ensure optimal performance and reliability in monitoring and managing air moisture levels, enhancing the efficiency and safety of compressed air operations across various industries.

Trust HENGKO to deliver superior, customized sensor solutions that drive your success.

オンライン工業用露点測定 - HG602

主な特徴

HG602は高精度で信頼性の高い設計となっており、圧縮空気システムの効率的な管理に不可欠な露点測定を提供します。

- 測定範囲50℃~+20℃、多様な使用条件に対応。

- 圧力能力:0.1~5.0MPaの圧力に対応し、オプションで35MPa(350bar)までの高圧コンフィギュレーションが可能。

- アウトプットとコミュニケーション:4-20mAとHENGKOデジタル出力の両方を提供し、既存の制御システムとシームレスに統合できます。

- 電源:12-30Vdc、60mAで効率よく動作。

- 設置の柔軟性:G1/2″オネジを採用したコンパクトなデザインで、IP65に適合し、簡単かつ確実に取り付けられます。

- 強化されたセンサー技術:新開発のセンサーを採用し、信号の安定性を向上、-50℃までの長期信頼性を実現。

- 多彩なフィッティング・オプション:プッシュフィットまたはファストコネクタを使用して、あらゆる配管スキームにフレキシブルに組み込むことができます。

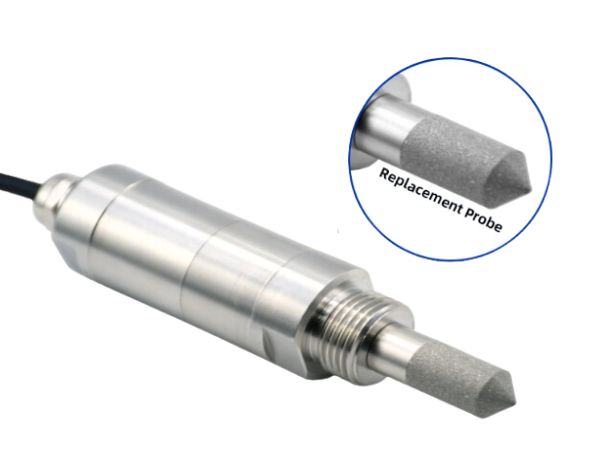

ハンドヘルド工業用露点計

- HG970シリーズ

主な特徴

HG970は、産業環境において卓越した性能を発揮するよう設計されており、耐久性に優れた交換可能な金属製プローブ設計により、長寿命と容易な取り付けを実現しています。

このハンドヘルド・メーターは、迅速かつ正確にデータを提供するよう設計されており、迅速かつ正確な水分検出のためのセンサー・パージ機能により、高速応答時間が大幅に向上している。

厳しい条件下での信頼性の高い測定:

HG970の堅牢なセンサーは結露に耐え、湿気にさらされても完全に回復するため、厳しい条件下でも信頼性の高い測定値を提供します。

ユーザビリティを向上させる直感的なユーザーインターフェース:

HG970は、データの明確な視覚化を提供する使いやすいグラフィカルLCDディスプレイを装備しています。その直感的なインターフェースと広範なデータロギング機能により、外出先での包括的な水分分析に理想的なツールとなっています。

HG970meterは、様々な産業環境において、迅速で正確な露点測定と信頼性の高い性能を必要とするプロフェッショナルに最適です。

Why Need Dew-Point Measurements in Compressed Air ?

Dew-point measurements used in compressed air systems are crucial for several reasons, particularly in industrial settings where air quality directly impacts the operation and efficiency of pneumatic equipment and processes. As follow reasons are essential we list, please check :

Preventing Moisture Damage: Compressed air often contains moisture, which can condense into water droplets if the temperature of the air falls below the dew point. This condensation can lead to corrosion and damage in piping, equipment, and instrumentation. By measuring the dew point, you can ensure that the moisture content in the compressed air is at a safe level to prevent such damage.

Ensuring Product Quality: In many manufacturing processes, such as in pharmaceuticals, electronics, and food production, moisture can compromise the quality of the product. For example, excessive moisture can affect the coating processes, create defects in painting or lead to contamination. Dew-point measurements help maintain the required air quality standards to ensure product integrity.

Energy Efficiency: Running a dryer to reduce moisture in compressed air consumes energy. By accurately measuring and controlling the dew point, industries can optimize the operation of air dryers, ensuring they are used only when necessary, thereby saving energy and reducing operational costs.

Compliance with Standards: Various industries are governed by standards that dictate specific air quality levels, including moisture content. Dew-point measurements are a direct method to verify compliance with these standards, such as ISO 8573-1, which defines air quality levels, including moisture.

Safety: In processes where compressed air comes into contact with highly reactive materials or is used in environments where there is a risk of explosion, controlling moisture is critical. Moisture in compressed air can significantly increase the risk of fire and explosion in such settings.

Operational Reliability: Proper dew-point measurement and control can increase the reliability of pneumatic tools and equipment powered by compressed air. Moisture can lead to pneumatic system malfunctions, frequent maintenance requirements, and shortened equipment lifespans.

Anyway, monitoring the dew point in compressed air systems is vital for maintaining equipment reliability, ensuring product quality, improving energy efficiency, achieving compliance with industry standards, and ensuring safety in manufacturing environments.

How to Choose Dew Point Sensor for Compressed Air

Choosing the right dew point sensor for a compressed air system is essential to ensure accurate monitoring and control of moisture, which can greatly impact system efficiency and product quality.

Here are some key considerations when selecting a dew point sensor:

- 測定範囲: Ensure the sensor covers the temperature extremes your system may face.

- 精度: Opt for high accuracy and repeatability to maintain precise moisture control.

- 応答時間: Choose a sensor with a quick response to rapidly changing conditions.

- Operating Pressure: Select a sensor rated for the system’s pressure to ensure durability and accurate readings.

- Resistance to Contaminants: Pick a sensor resistant to oils, chemicals, or particulates prevalent in your environment.

- Ease of Installation and Maintenance: Favor sensors that are straightforward to install and maintain.

- Output and Connectivity: Ensure compatibility with your existing monitoring systems, considering options like 4-20 mA, 0-10 V, or digital outputs.

- 環境条件: Verify that the sensor can withstand the specific environmental conditions it will face.

- Cost and Warranty: Balance the sensor’s cost with your budget and prioritize a good warranty for added security.

By carefully considering these factors, you can choose a dew point sensor that meets the specific needs of your compressed air system, ensuring efficient operation and protection against moisture-related issues.

適切な温湿度トランスミッターを見つける

今すぐプロジェクトをお知らせください

モニタープロジェクトの詳細をお聞かせください、

私たちは3日以内に競争力のある価格で最高のソリューションを提供します。

私たちは3日以内に競争力のある価格で最高のソリューションを提供します。

よくあるご質問

What is a dew point sensor for compressed air, and why is it important?

- A dew point sensor is a device that measures the dew point of compressed air. The dew point is the temperature at which water vapor in the air condenses into liquid water. In compressed air systems, moisture can cause a number of problems, including:

- Corrosion of pipes and equipment

- Reduced efficiency of pneumatic tools and machinery

- Growth of mold and bacteria

- Contamination of products

By measuring the dew point of compressed air, you can ensure that the air is dry enough to prevent these problems. This can help to save money on maintenance costs, improve product quality, and extend the life of your compressed air system.

What are the different types of dew point sensors for compressed air?

There are two main types of dew point sensors for compressed air:

- Chilled mirror dew point sensors: These sensors work by cooling a mirror until water vapor condenses on its surface. The temperature at which condensation occurs is the dew point. Chilled mirror dew point sensors are very accurate, but they can be expensive and require regular maintenance.

- Electrical capacitance dew point sensors: These sensors measure the change in electrical capacitance of a material as it absorbs moisture. Electrical capacitance dew point sensors are less expensive than chilled mirror sensors and are generally easier to maintain. However, they may not be as accurate as chilled mirror sensors, especially at very low dew points.

What factors should I consider when choosing a dew point sensor for compressed air?

When choosing a dew point sensor for compressed air, you should consider the following factors:

- The required accuracy: How important is it to have a very precise measurement of the dew point?

- The dew point range: What is the expected range of dew points in your compressed air system?

- The pressure and temperature of the compressed air: Some dew point sensors are not suitable for use with high-pressure or high-temperature compressed air.

- The ease of use and maintenance: How easy is it to install, calibrate, and maintain the sensor?

- The cost: How much are you willing to spend on a dew point sensor?

How often should I calibrate my dew point sensor?

The frequency of calibration for a dew point sensor will depend on the specific sensor and the application. However, it is generally recommended to calibrate dew point sensors at least once a year. Some sensors may require calibration more frequently, depending on the use and environment.

Where should I install a dew point sensor in my compressed air system?

The ideal location for a dew point sensor will depend on your specific compressed air system. However, some general guidelines include:

- Installing the sensor after the air dryer to monitor the performance of the dryer.

- Installing the sensor at a point where the compressed air is used in a critical application.

- Avoiding locations where the sensor may be exposed to extreme temperatures or contaminants.

スプレッド・ザ・ワールド

HENGKOは、産業用センサーソリューションのグローバルリーダーであり、ユニークなデザインと優れた性能に定評があります。当社の温度・湿度トランスミッターとセンサーは、食品・飲料、製薬、製造、環境モニタリングなど、幅広い産業分野で使用されています。

0

+

経験年数

0

世界販売

0

K