HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more

Reliable OEM Partner for Dew Point Monitoring in Compressed Air, Gas, and Drying Systems

Início " Medidor de ponto de orvalho

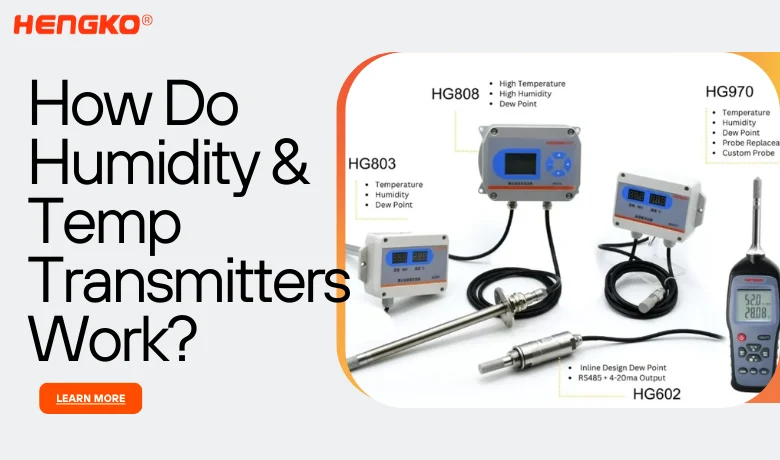

Designed for precision and durability, the HENGKO HG970 series offers a reliable dew point monitoring solution for demanding industrial environments. With high accuracy, fast response time, and robust stainless steel construction, the HG970 is ideal for continuous online measurement in compressed air systems, gas drying lines, and moisture-sensitive production processes. Whether you need analog or digital output, the HG970 series ensures stable performance and seamless integration into your control systems.

HG970 Series Dew Point Meter/ Temperature Humidity Selection Guide

| Modelo | Faixa de temperatura | Measurement Ranges (Humidity / Dew Point / Wet Bulb) | Accuracy (Temp / RH / Dew Point) | Tipo de sonda | Aplicativo | Features / Notes |

| HG970 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Replaceable Probe | General-purpose monitoring in HVAC systems, laboratories, and industrial rooms | Standard model with easy-to-replace probe for regular maintenance |

| HG972 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Round Probe | Compact systems like environmental test chambers, storage cabinets, or small control boxes | Space-saving round probe for tight installations |

| HG984 | -30 ~ 80℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | OEM Sharp Probe | OEM integration in compact equipment, sensor assemblies, or instrument panels | Custom sharp probe for embedded and OEM applications |

| HG983 | -30 ~ 100℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Long Sharp Probe | Compressed air pipelines, drying ovens, and tank inlets | Extended reach probe ideal for insertion into ducts or deep ports |

| HG981 | -30 ~ 120℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | OEM Long Probe | Lithium battery drying rooms, petrochemical high-temp gas lines | Long and durable probe for harsh, high-temperature applications |

| HG982 | -30 ~ 120℃ | Humidity Range: 0 ~ 100%RH / Dew Point Range: -30 ~ 80°C Td / Wet Bulb Range: 0 ~ 60°C WB | ±0.1℃ / ±1.5%RH / ±3°C Td | Split Sharp Probe | Industrial dryers, heated air chambers, or environments with difficult access | Split design for easier installation and probe positioning |

Série HG970

Portable Dew Point Meter HG970 – Precision in Your Pocket

The Portable Dew Point Meter is a lightweight, field-ready device designed for fast,

accurate humidity and dew point measurements in a wide range of environments.

*Compact & Portable – Ideal for mobile use in field inspections and remote sites

*High Accuracy – Advanced sensors ensure precise dew point readings

*Versatile Applications – Suitable for HVAC checks, industrial spot measurements, and environmental monitoring

*Rapid Response – Quickly adapts to changing conditions for real-time results

*User-Friendly Interface – Simple controls and clear display for effortless operation

*Durable & Lightweight – Built to withstand demanding field conditions without added bulk

*Essential Tool – A must-have for professionals requiring reliable moisture data on the go

A HENGKO é líder global em soluções de sensores industriais, com uma reputação de design exclusivo e excelente desempenho. Nossos transmissores e sensores de temperatura e umidade são usados em uma ampla gama de setores, incluindo alimentos e bebidas, farmacêutico, manufatura e monitoramento ambiental.

Você pode personalizar totalmente um produto exclusivo de sensor de ponto de orvalho com base em nossa série de transmissores de ponto de orvalho patenteados e projetados por nós mesmos.

Você obterá um preço muito mais baixo e competitivo devido ao nosso controle extremamente econômico.

Você sempre atenderá às necessidades do mercado em constante mudança com nossos produtos em constante atualização.

Você terá um forte suporte de marketing para ajudá-lo a vender produtos com sucesso. Os suportes materiais incluem: imagens de produtos em alta resolução, vídeos legais com efeito 3d e MUITO mais.

Sensor de ponto de orvalho para monitorar o sistema de ar comprimido: garantindo o controle ideal da umidade e da qualidade do ar para a sua máquina de compressão de ar

HENGKO is a trusted manufacturer of high-performance dew point transmitters, temperature and humidity transmitters, and portable dew point meters.

We specialize in delivering a comprehensive range of monitoring solutions tailored to meet the precise needs of industrial and environmental applications.

Engineered for accuracy, durability, and long-term stability, our products ensure reliable performance across demanding conditions. Whether you’re looking for a precise dew point sensor or a rugged humidity transmitter, HENGKO offers both the technology and expertise to support your project.

👉 Contact us today to explore customized solutions that fit your monitoring challenges.

A Medidor de ponto de orvalho is a precision instrument used to measure the dew point temperature—the temperature at which moisture in the air or gas begins to condense into liquid water. It is a key parameter for understanding humidity levels e moisture content in various industrial and environmental applications.

Medidas dew point temperature in °C or °F

Indicates humidity saturation in air or gases

Helps detect moisture contamination in compressed air, gases, or controlled environments

Compressed air systems (prevent water accumulation)

Gas drying processes (e.g. nitrogen, argon, hydrogen)

Sistemas HVAC (ensure indoor climate control)

Lithium battery dry rooms (moisture-sensitive environments)

Pharmaceutical & food production (humidity-sensitive storage)

| Tipo | Descrição |

|---|---|

| Portable Dew Point Meter | Handheld, used for spot-checks and field diagnostics |

| Online Dew Point Transmitter | Fixed installation, sends real-time data to control systems (e.g. 4–20 mA, RS485) |

| Mirror-type Hygrometer | Laboratory-grade, ultra-accurate but costly |

Prevents corrosion, condensation, and product defects

Ensures compliance with industry standards (ISO, GMP, etc.)

Enhances energy efficiency and equipment lifespan

Checking the dew point with the HG970 series portable dew point meter from HENGKO is a precise, efficient, and reliable process designed for both industrial field inspections and laboratory-quality measurements. The HG970 series offers various probe configurations to suit a wide range of applications, from general HVAC systems to high-temperature drying environments. Below is a step-by-step guide and technical overview of how the dew point measurement is conducted using this instrument.

The HG970 series includes multiple probe types (e.g., replaceable, sharp, long, split) and temperature ranges (-30°C to 120°C), allowing users to choose the most suitable model based on their measurement environment. For example:

HG970 / HG972: Ideal for general industrial and HVAC applications.

HG981 / HG982: Recommended for high-temperature environments (80–120°C), such as lithium battery drying rooms and gas pipelines.

Ensure the device is powered (via external power supply or field setup).

Connect the probe securely to the test point, pipe port, or environmental chamber.

For accurate results, avoid exposing the sensor to sudden humidity shocks or contaminants like oil or dust before the reading stabilizes.

Once connected, the HG970’s built-in sensing module continuously samples the air or gas, measuring parameters such as:

Dew Point Temperature (°C or °F)

Relative Humidity (%RH)

Ambient Temperature (°C/°F)

These values are calculated using HENGKO’s advanced polymer capacitive or ceramic sensor technology, offering fast response time e high accuracy even in dynamic or high-moisture environments.

If the model includes an LCD or digital interface (optional), the readings are displayed in real-time. For models without a display, the output is transmitted via:

Analog Signal (4–20 mA / 0–10 V)

Digital Communication (RS485 / Modbus-RTU)

These outputs can be logged via a data logger, PLC, or remote monitoring software.

The dew point temperature tells you the exact point at which condensation would occur under current pressure and humidity conditions. Lower dew points indicate drier air, which is critical for:

Preventing corrosion or moisture damage in pneumatic tools or compressed air systems

Maintaining strict humidity control in cleanrooms, dry rooms, or gas drying processes

For example:

Dew point < -40°C: Suitable for high-purity gas systems and lithium battery environments.

Dew point 0 ~ 10°C: Typical in HVAC, food storage, and general industrial applications.

To maintain reliable performance:

Calibrate the device periodically (typically once every 6–12 months) against a traceable standard.

Clean or replace the sensor probe as needed, especially if used in harsh or dusty environments.

Store the unit in a dry and clean place when not in use.

✅ Wide temperature and humidity range

✅ Interchangeable probe options for different environments

✅ Compact and robust construction for field use

✅ High accuracy and fast response time

✅ Optional OEM customization for unique industrial requirements

Contact HENGKO’s technical team at ka@hengko.com or visit www.hengkometer.com to get personalized advice based on your industry, installation method, and measurement conditions.

O HG970 series dew point transmitters from HENGKO are designed for industrial-grade dew point monitoring with high precision and stability. The normal dew point measurement range of the HG970 series is typically:

-60°C to +60°C Td (typical)

(Custom ranges available upon request)

| Parameter | Detalhes |

|---|---|

| Typical Range | -60°C ~ +60°C dew point (Td) |

| Faixa de umidade | 0%RH to 100%RH |

| Faixa de temperatura | -30°C to +120°C (varies by model, e.g., HG970 to HG982) |

| Sensor Type | Polymer capacitive or ceramic sensor (high accuracy, fast response) |

| Sinal de saída | 4–20mA, 0–5V, 0–10V, RS485 / Modbus-RTU |

| Precisão | ±2°C Td typical (customizable based on sensor class) |

-60°C to -20°C Td: Ideal for compressed air drying systems, lithium battery dry roomsou gas drying

-20°C to +20°C Td: Common in Sistemas HVAC, pharmaceutical environmentse storage facilities

+20°C to +60°C Td: Suitable for high-moisture process areasou climate chambers

If you need a customized dew point range, HENGKO can tailor the sensor configuration based on:

Target environment (dry gas, ambient air, high temp zone)

Accuracy requirement

Signal output preferences

📩 Contact: ka@hengko.com to request a custom specification or get technical support.

This is Great question!

Understanding the difference between ponto de orvalho e umidade is key to accurately evaluating air moisture content

—especially in industrial, HVAC, and environmental monitoring applications.

| Aspect | Ponto de orvalho | Humidity (Relative Humidity, %RH) |

|---|---|---|

| Definição | O temperatura at which air becomes fully saturated and water vapor condenses into liquid | O percentage of water vapor in the air compared to the maximum it can hold at a given temperature |

| Unit | °C or °F (Temperature) | %RH (Percentage) |

| Absolute/Relative? | Absolute measure of moisture content | Relative measure (depends on air temperature) |

| Temperature Dependent? | No – dew point is not affected by ambient temperature | Yes – higher temperatures can hold more moisture, affecting %RH |

| What it tells you | How dry or moist the air actually is | How close the air is to saturation at a given temperature |

| Usado para | Precise control in drying, gas purity, industrial process monitoring | General comfort, climate control, environmental monitoring |

| Example | Dew point of -40°C = extremely dry air (used in lithium battery rooms) | 60%RH at 25°C = moderately humid air |

Ponto de orvalho = “How much water is really in the air?”

Relative Humidity = “How full is the air’s moisture tank at this temperature?”

| Ambient Temp | Ponto de orvalho | Relative Humidity |

|---|---|---|

| 25°C | 10°C | ~45%RH |

| 25°C | 20°C | ~75%RH |

| 25°C | 24°C | ~95%RH |

Uso Ponto de orvalho for:

Compressed air drying systems

Inert gas monitoring (N₂, Ar, H₂)

Lithium battery dry rooms

Uso %RH for:

Indoor air quality

HVAC system control

Agricultural storage

Even though the temperature is the same, the dew point increases with more water vapor in the air, which raises the relative humidity.

Both devices are used to measure the dew point temperature, a critical parameter in determining moisture levels in air or gas. However, they differ significantly in design, applicatione integration method.

| Aspect | Descrição |

|---|---|

| Measurement Function | Both measure dew point temperature accurately to detect moisture levels |

| Sensor Technology | Typically use similar capacitive or ceramic humidity sensors |

| Target Media | Both used with air, compressed gases, dry gases, etc. |

| Aplicativos | Found in industrial, HVAC, environmental monitoringe gas drying |

| Feature / Aspect | Medidor de ponto de orvalho | Transmissor de ponto de orvalho |

|---|---|---|

| Form Factor | Portable or handheld | Fixed-installation / inline sensor |

| Display | Built-in LCD or digital display | Usually no display (or optional), outputs data to external systems |

| Power Source | Battery-powered or rechargeable | Externally powered (e.g., 24V DC) |

| Sinal de saída | Internal data logging, USB export (optional) | Analog (4-20 mA, 0-10V) or Digital (RS485/Modbus-RTU) |

| Use Case | On-site spot checks, mobile inspections | Continuous online monitoring & automation systems |

| User Type | Technicians, maintenance staff | Engineers, system integrators, automation specialists |

| Instalação | Handheld use or temporary probe connection | Installed permanently in pipelines, dryers, tanks, etc. |

| Faixa de preço | Generally higher due to display and portability features | More cost-effective for long-term embedded use |

| Typical Examples | Vaisala DM70, Michell MDM300, HG970 series | HENGKO HG970, Vaisala DMT143, E+E EE371 |

| Scenario | Recommended Device |

|---|---|

| Field diagnostics and mobile inspections | Medidor de ponto de orvalho |

| Continuous monitoring in a compressed air line | Transmissor de ponto de orvalho |

| Temporary measurements in different locations | Medidor de ponto de orvalho |

| Integration into control/SCADA systems | Transmissor de ponto de orvalho |

Dew Point Meters are portable tools designed for manual measurements, great for spot-checking and troubleshooting.

Dew Point Transmitters are installed devices built for long-term, real-time monitoring e system automation.

A saída de 4-20 mA é uma escolha popular para sensores de ponto de orvalho porque é uma saída industrial padrão compatível com uma ampla gama de sistemas de controle. É também uma saída muito confiável e resistente a ruídos, o que a torna adequada para uso em ambientes industriais adversos.

Aqui estão algumas das vantagens de usar uma saída de 4-20 mA para sensores de ponto de orvalho:

Compatibilidade: A saída de 4-20 mA é compatível com uma ampla gama de sistemas de controle, incluindo PLCs, DCSs e sistemas SCADA. Isso facilita a integração dos sensores de ponto de orvalho aos sistemas de controle existentes.

Confiabilidade: A saída de 4-20 mA é uma saída muito confiável que não é suscetível à interferência de ruídos. Isso é importante para os sensores de ponto de orvalho, que geralmente são usados em ambientes industriais adversos.

Precisão: A saída de 4-20 mA pode fornecer medições precisas do ponto de orvalho. Isso é importante para aplicações em que é necessário um controle preciso do ponto de orvalho.

Alcance: A saída de 4-20 mA pode abranger uma ampla faixa de valores de ponto de orvalho. Isso o torna adequado para uma variedade de aplicações.

Custo: A saída de 4-20 mA é uma saída relativamente barata de implementar. Isso a torna uma opção econômica para sensores de ponto de orvalho.

Além das vantagens listadas acima, a saída de 4-20 mA também é uma saída muito versátil. Ela pode ser usada para transmitir uma variedade de outros parâmetros, como temperatura, pressão e taxa de fluxo. Isso a torna uma saída valiosa para uma ampla gama de aplicações industriais.

Aqui estão alguns exemplos de aplicações em que os sensores de ponto de orvalho com saídas de 4-20 mA são comumente usados:

Sistemas de ar comprimido: Os sensores de ponto de orvalho são usados em sistemas de ar comprimido para monitorar e controlar o teor de umidade do ar. Isso é importante para evitar corrosão e outros danos ao equipamento.

Sistemas HVAC: Os sensores de ponto de orvalho são usados em sistemas HVAC para controlar os níveis de umidade em edifícios. Isso é importante para o conforto e a saúde das pessoas.

Processos de secagem industrial: Os sensores de ponto de orvalho são usados em processos de secagem industrial para monitorar e controlar o teor de umidade do produto que está sendo seco. Isso é importante para garantir a qualidade do produto.

Processamento de alimentos e bebidas: Os sensores de ponto de orvalho são usados no processamento de alimentos e bebidas para controlar o teor de umidade do produto que está sendo processado. Isso é importante para garantir a segurança e a qualidade do produto.

Monitoramento ambiental: Os sensores de ponto de orvalho são usados em estações de monitoramento ambiental para rastrear as mudanças no teor de umidade na atmosfera. Essas informações podem ser usadas para prever as condições climáticas e identificar possíveis problemas ambientais.

Como você pode ver, os sensores de ponto de orvalho com saídas de 4-20 mA são uma ferramenta valiosa para uma ampla gama de aplicações industriais. Eles são confiáveis, precisos e versáteis, e podem ser facilmente integrados aos sistemas de controle existentes.

O preço dos transmissores de ponto de orvalho pode variar de acordo com o fabricante, os recursos e a precisão do transmissor. Em geral, os transmissores de ponto de orvalho com maior precisão e mais recursos custarão mais do que os transmissores de ponto de orvalho com menor precisão e menos recursos.

Com base em minha pesquisa, eu diria que o preço dos transmissores de ponto de orvalho é geralmente justo. O custo dos componentes e da mão de obra necessários para fabricar transmissores de ponto de orvalho é alto, e as empresas que fabricam transmissores de ponto de orvalho precisam recuperar esses custos para se manterem no mercado. Além disso, os transmissores de ponto de orvalho são usados em várias aplicações críticas, portanto, é importante que sejam confiáveis e precisos. O alto preço dos transmissores de ponto de orvalho reflete o fato de que eles são instrumentos de alta qualidade nos quais se pode confiar para fornecer medições precisas.

Aqui estão alguns fatores que podem afetar o preço de um transmissor de ponto de orvalho:

Aqui está uma tabela com a faixa de preço dos transmissores de ponto de orvalho no mercado:

| Tipo | Faixa de preço |

|---|---|

| Espelho refrigerado | $2,000 – $10,000 |

| Polímero | $500 – $2,000 |

| Óxido metálico | $500 – $1,500 |

Como você pode ver, a faixa de preço dos transmissores de ponto de orvalho pode variar dependendo do tipo de transmissor. Os transmissores de ponto de orvalho de espelho resfriado são o tipo mais caro de transmissor, mas também são os mais precisos. Os transmissores de ponto de orvalho de polímero e óxido metálico são mais baratos, mas também são menos precisos.

O preço dos transmissores de ponto de orvalho também pode variar de acordo com os recursos do transmissor. Por exemplo, os transmissores de ponto de orvalho com registro de dados, pontos de ajuste de alarme e recursos de acesso remoto normalmente custam mais do que os transmissores de ponto de orvalho com menos recursos.

Se estiver procurando um transmissor de ponto de orvalho de alta qualidade, eu recomendaria comprar um de uma marca conhecida que tenha boa reputação de qualidade e confiabilidade. Você também deve considerar os recursos que são importantes para você e a precisão necessária. Se não tiver certeza de qual transmissor de ponto de orvalho é o ideal para você, recomendo consultar um profissional que possa ajudá-lo a tomar uma decisão informada.

some questions about Dew Point Meter you like to know

A Medidor de ponto de orvalho is a precision instrument used to measure the dew point temperature — the temperature at which air or gas becomes saturated with moisture and water vapor begins to condense into liquid.

It works by sensing the relative humidity and temperature of the environment or gas stream, then calculating the dew point based on the current saturation level. Most modern dew point meters use capacitive or ceramic sensors for real-time measurements, offering high accuracy and stability across a wide range of industrial applications.

Dew point measurement is critical for moisture control, especially in applications where excess humidity can lead to equipment failure, corrosion, product spoilage, or safety risks.

Industries such as sistemas de ar comprimido, pharmaceuticals, lithium battery manufacturing, semiconductorse food packaging depend on dew point monitoring to ensure dry environments and gas purity. In compressed air lines, for example, a low dew point prevents water buildup, which could otherwise damage tools and contaminate end products.

Ponto de orvalho é o absolute temperature at which air becomes saturated and water vapor condenses, while humidity (usually relative humidity) is a percentage expressing how much moisture the air currently holds compared to its maximum capacity at a given temperature.

In simple terms:

Ponto de orvalho tells you how much moisture is actually in the air (in °C or °F).

Relative humidity tells you how close the air is to saturation (in %RH).

Dew point is more accurate for industrial applications, especially when monitoring drying processes or compressed air systems.

In industrial compressed air systems, the target dew point depends on the drying method e application sensitivity:

| Aplicativo | Recommended Dew Point |

|---|---|

| General industrial use | -20°C to -40°C |

| Instrumentation or electronics | -40°C to -70°C |

| Medical/Pharma cleanrooms | ≤ -40°C |

| Standard shop air (non-critical) | 0°C to -10°C |

A lower dew point means drier air, which is essential for high-performance or sensitive operations. The dew point meter helps monitor this and ensure system compliance.

Yes. Most dew point meters — including advanced portable models — can be used to measure dew point in a variety of non-corrosive gases, such as nitrogen (N₂), argon (Ar), carbon dioxide (CO₂)e compressed natural gas (CNG).

However, it is important to verify:

Sensor compatibility with the target gas

Pressure rating of the probe or housing

Flow regulation to avoid sensor contamination

Some models, like the HENGKO HG970 series, offer custom probe materials and protective filters for specialized gas monitoring applications.

For most industrial and professional uses, dew point meters should be calibrated every 6 to 12 months, depending on usage frequency, environmental conditions, and accuracy requirements.

Regular calibration:

Ensures data reliability

Mantém regulatory compliance (e.g., ISO, GMP)

Extends the lifespan of the sensor

HENGKO and other manufacturers often offer traceable calibration services and replacement sensors for field units.

Typical high-quality portable dew point meters can measure within a range of:

-80°C to +60°C (or -112°F to +140°F)

For example, the HG970 series by HENGKO is commonly used to monitor dew point ranges from -60°C to +60°C, making it suitable for most industrial air and gas drying applications. Some lab-grade mirror hygrometers may extend lower, but portable models balance range with portability and cost-effectiveness.

Using a portable dew point meter is straightforward:

Power on the device (battery or external power).

Connect the probe to the sample point or open environment.

Allow stabilization time (usually 30 seconds to a few minutes).

Observe the real-time dew point reading on the display or via signal output.

Log or export data if required (some models offer USB or Bluetooth).

Always make sure the sensor is clean, calibrated, and not exposed to oil, dust, or corrosive chemicals.

A Medidor de ponto de orvalho is portable and often used for spot-checking or mobile diagnostics.

A Transmissor de ponto de orvalho is a fixed, inline sensor installed for continuous monitoring in automated systems.

Dew point meters typically include a display and internal battery, while transmitters are integrated with PLCs or data loggers via analog (4-20mA) or digital (RS485/Modbus) output.

Yes — if it’s rated for industrial or field use. Look for:

IP-rated housing for dust and moisture protection

Stainless steel probe construction

Temperature range compatibility (e.g., -30°C to +120°C)

Shock-resistant casing

Models like the HENGKO HG970 series are designed for demanding conditions, including outdoor gas lines, drying towersou factory production lines.

Entre em contato com a HENGKO hoje mesmo para esclarecer qualquer dúvida sobre sensores, transmissores e soluções de temperatura e umidade

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more

Effective moisture management is essential in facilities where materials, equipment, and processes depend on controlled

In short, Humidity and temperature transmitters measure and send environmental data to control systems. They

Why Are Dryer Dew Point Meters Critical for Compressed Air Systems? Maybe You always battle

Por que uma zona do escritório está muito úmida e como um transmissor de umidade resolve o problema Persistente

Entre em contato com a nossa equipe de especialistas para obter assistência personalizada e forneceremos prontamente as melhores soluções de transmissores e sensores de temperatura e umidade adaptadas às suas necessidades específicas.

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many

Effective moisture management is essential in facilities where materials, equipment,

In short, Humidity and temperature transmitters measure and send environmental