Introdução

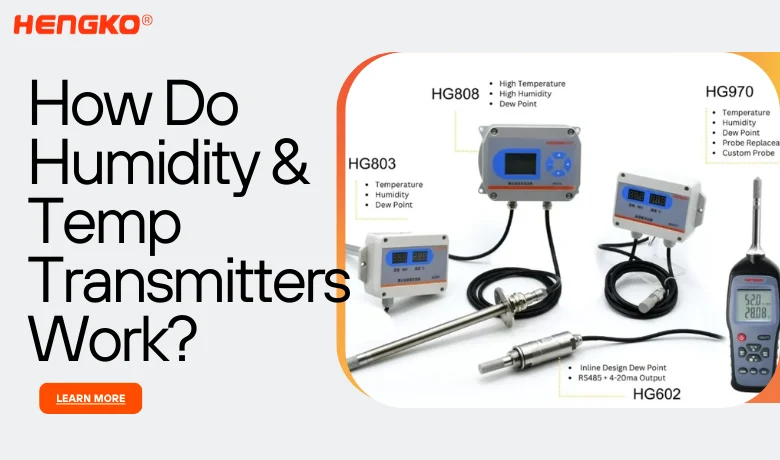

In industrial environments, small deviations in temperature or humidity can cause big problems—think of pharmaceutical cleanrooms where product quality depends on strict climate control, or data centers where excess humidity risks static damage. That’s why industries don’t just use ordinary home-grade sensors; they rely on industrial humidity and temperature transmitters.

Unlike consumer sensors that only measure conditions locally, transmitters are designed for accuracy, durability, and seamless integration with industrial control systems. They don’t just detect temperature and humidity; they convert the measurements into stable signals that PLCs, DCS systems, or building automation systems can easily read. In short, transmitters are the bridge between physical conditions and industrial decision-making.

Basics of Humidity and Temperature Measurement

Before understanding how transmitters work, it’s important to look at how the sensing elements themselves detect environmental changes:

●Humidity Measurement

Capacitive sensors: The most common in industrial applications. A thin polymer film absorbs moisture, causing a change in capacitance. Known for high stability and broad humidity range.

Resistive sensors: Humidity alters the resistance of a hygroscopic material. Simpler, but less accurate than capacitive.

Thermal conductivity sensors: Measure the difference in heat conductivity between dry air and humid air, often used for extreme or special environments.

●Temperature Measurement

RTDs (Resistance Temperature Detectors): Platinum RTDs (like Pt100, Pt1000) are widely used for their precision and long-term stability.

Thermistors: Sensitive and responsive, but better suited for narrower ranges.

Thermocouples: Cover very wide temperature ranges, often in more demanding industrial processes.

Essentially, these sensing elements respond to environmental changes by altering electrical properties such as resistance, capacitance, or voltage. This raw signal is the starting point—what comes next is where transmitters step in to make the data usable in industrial systems.

From Sensor to Transmitter: How It Works

Raw signals from sensors are often weak, unstable, or nonlinear. Industrial transmitters turn these into reliable outputs:

●Signal Detection

·The sensor element responds to humidity or temperature changes, producing a small electrical variation (resistance, capacitance, or voltage).

●Signal Conditioning

·The transmitter processes the raw signal: amplifying, filtering out noise, and applying temperature compensation or linearization.

·This ensures the output is accurate and stable even in harsh environments with electrical interference.

●Signal Conversion

Once conditioned, the signal is converted into standardized industrial outputs:

·4–20 mA current loop: Highly resistant to signal loss over long cable runs, widely used in factories.

·0–10 V voltage output: Simple, but more vulnerable to interference compared with current loops.

·Digital outputs: RS485, Modbus, or BACnet, enabling integration with modern PLCs, DCS systems, and building automation networks.

●System Integration

·The transmitter delivers these stable outputs to control systems, where data can be logged, analyzed, and used for process control.

·Alarms can be triggered automatically if values exceed thresholds, ensuring real-time protection.

In essence, the transmitter doesn’t just measure—it ensures the data is trustworthy, scalable, and ready for industrial decision-making. Without this conversion and stabilization, environmental monitoring in complex industrial setups would be unreliable.

Key Features in Industrial Transmitters

Industrial environments are demanding—dust, moisture, temperature fluctuations, and electromagnetic interference are daily challenges. To perform reliably in such conditions, humidity and temperature transmitters are engineered with specific features that go far beyond those of consumer-grade devices:

●Rugged Housing

·Transmitters are typically enclosed in IP65/IP67-rated housings, protecting against dust and water ingress.

·Corrosion-resistant materials like stainless steel or high-grade polymers ensure long-term durability, even in chemical or high-humidity environments.

●Wide Measurement Range and High Accuracy

·Industrial processes often require monitoring from very low humidity up to near-saturation conditions.

·High-precision sensing elements, combined with signal conditioning, deliver reliable readings even in critical environments like cleanrooms or cold storage.

●Long-Term Stability and Calibration Options

·Drift is inevitable in any sensor, but industrial transmitters are designed for minimal long-term drift.

·Many models allow recalibration or sensor replacement without interrupting production, ensuring consistent accuracy.

●Resistance to Harsh Conditions

·Built to withstand temperature extremes, condensation, and continuous high humidity.

·Shielded designs minimize the impact of electromagnetic interference from heavy machinery or power lines.

●Flexible Output Signals

·Support for analog signals (4–20 mA, 0–10 V) and digital protocols (Modbus, BACnet, RS485) ensures compatibility with both legacy and modern control systems.

These features make transmitters not just measurement devices, but critical components of industrial reliability and safety. By ensuring that environmental data is accurate and consistent, they help industries maintain compliance, reduce downtime, and protect both products and equipment.

Applications in Industrial Environments

Humidity and temperature transmitters play a mission-critical role across a wide range of industries. Wherever environmental stability affects product quality, safety, or equipment performance, transmitters become indispensable. Some key applications include:

●Pharmaceuticals & Biotechnology

·In cleanrooms and laboratories, even slight fluctuations in humidity or temperature can compromise drug quality.

·Transmitters ensure strict compliance with GMP and FDA regulations, monitoring conditions in production, storage, and freeze-drying (lyophilization) processes.

●HVAC & Building Automation

·Industrial facilities, hospitals, and office complexes rely on transmitters to maintain indoor air quality and optimize energy use.

·Integrated with building management systems, they help balance comfort with efficiency.

●Food & Beverage Industry

·From fermentation rooms to cold-chain logistics, precise environmental monitoring is essential to prevent spoilage and ensure consistent product quality.

·Transmitters provide continuous, reliable data for process control and regulatory compliance.

●Data Centers & Electronics Manufacturing

·Excess humidity can lead to condensation and corrosion, while overly dry conditions increase the risk of static discharge.

·Transmitters help maintain the narrow environmental band required for safe equipment operation.

●Manufacturing & Process Control

·In sectors such as chemical, textile, and paper production, humidity and temperature directly influence material properties and process outcomes.

·Real-time monitoring ensures process stability, product uniformity, and reduced downtime.

In each of these cases, the transmitter does more than collect data—it serves as a guardian of quality, safety, and efficiency, ensuring that industries can operate with confidence in demanding environments.

Advantages of Industrial Humidity and Temperature Transmitters

Industrial transmitters are more than just measurement devices—they are critical tools for reliable process control and environmental monitoring. Their main advantages include:

●High Accuracy and Stability

Designed to deliver precise measurements over long periods, ensuring consistent data even under demanding conditions.

Advanced compensation and signal conditioning minimize drift and error.

●Robust and Durable Design

Built with rugged housings that resist dust, moisture, and corrosion.

Capable of operating in extreme environments such as high humidity, rapid temperature shifts, or areas with strong electromagnetic interference.

●Seamless System Integration

Standardized outputs like 4–20mA, 0–10V, Modbus, or BACnet allow easy connection to PLCs, DCS, or building automation systems.

Support for both analog and digital communication makes them adaptable to modern and legacy infrastructures.

●Long-Term Reliability and Maintainability

Low drift design reduces the need for frequent recalibration.

Many models support field calibration or probe replacement, lowering maintenance costs and downtime.

●Compliance with Industry Standards

Developed to meet strict requirements in industries such as pharmaceuticals, food processing, and data centers.

Provide the assurance needed for audits, certifications, and regulatory compliance.

With these advantages, humidity and temperature transmitters become trusted guardians of product quality, process safety, and operational efficiency in industrial environments.

Conclusão

Humidity and temperature transmitters may look like simple devices, but in industrial environments, they act as the eyes and ears of process control. From pharmaceuticals and food production to data centers and manufacturing plants, these transmitters deliver accurate, stable, and reliable data—ensuring safety, quality, and compliance every step of the way.

By converting raw sensor signals into usable outputs for control systems, they make environmental data actionable, supporting smarter decisions and smoother operations. In short, they are not just measuring instruments, but key enablers of industrial reliability and efficiency.

Looking for a reliable temperature and humidity transmitter that fits your industrial needs? Contact HENGKO today to customize a solution for your application.