In modern biomanufacturing, fermentation is a critical step that directly affects product yield, purity, and consistency—whether it’s for antibiotics, enzymes, amino acids, or biofuels. Behind successful fermentation is not only a precise biological process but also a tightly controlled environment. Among all environmental factors, temperature and humidity are two of the most influential yet challenging to manage.

This article explores the core monitoring requirements for fermentation environments and introduces HG808-H Temperature and Humidity Transmitter, an advanced solution tailored for this application.

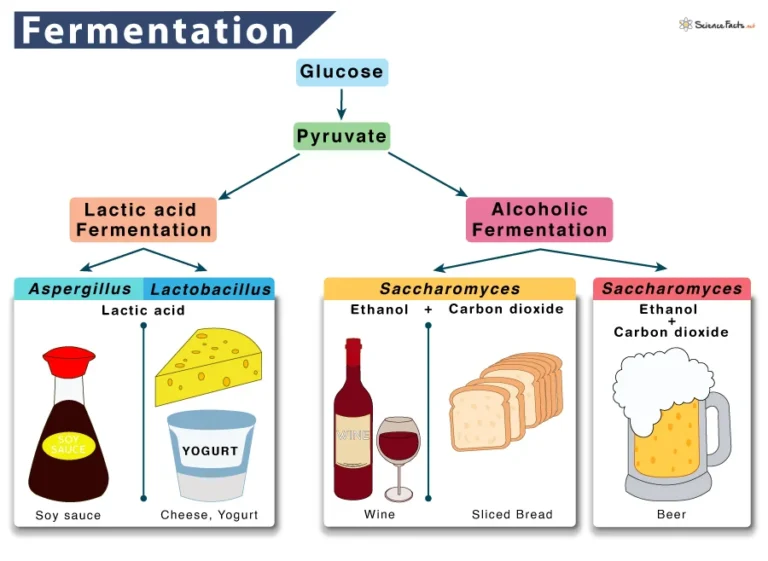

What is Fermentation?

Fermentation is a metabolic process in which microorganisms, such as bacteria, yeast, or fungi, convert organic compounds—typically carbohydrates—into alcohols, acids, or gases under anaerobic conditions. This biochemical reaction is widely used in food production, pharmaceuticals, and biofuel industries. In fermentation workshops, precise control of temperature and humidity is critical, as these factors directly influence microbial activity, product yield, and quality. Proper environmental management ensures optimal fermentation efficiency and consistency. This article explores key strategies for maintaining ideal conditions in fermentation processes.

Why Accurate Environmental Monitoring Matters

Fermentation is a highly sensitive biological process. Even minor fluctuations in temperature or humidity can lead to major consequences—such as reduced yields, altered product composition, or microbial contamination.

In industries like soy sauce brewing, vinegar fermentation, and alcohol production, the stakes are especially high. Maintaining optimal environmental conditions isn’t just about improving efficiency—it’s about ensuring product consistency, meeting strict regulatory standards, and protecting consumer health.

Accurate temperature and humidity monitoring forms the backbone of effective process control. It enables operators to make real-time adjustments, prevent batch failures, and achieve high-quality, repeatable results.

Impact of Temp & RH on Microbial Performance

Temperature and relative humidity (RH) play a fundamental role in determining the growth, metabolism, and viability of microorganisms used in fermentation. Each microbial strain—whether Saccharomyces cerevisiae, Lactobacillus, or Aspergillus oryzae—has a specific optimal temperature and humidity range where its metabolic activity peaks. Deviations outside these parameters can dramatically alter fermentation outcomes.

At elevated temperatures, microbial enzymes may denature, reducing catalytic efficiency. Conversely, low temperatures slow down cell division and metabolite production, leading to extended fermentation cycles. Even a ±1°C shift from the optimal range can affect growth curves, yield profiles, and by-product concentrations.

Relative humidity is equally critical—especially in solid-state or surface fermentation where ambient moisture supports microbial hydration. In environments with RH below the ideal threshold, microbial stress responses can trigger sporulation, dormancy, or autolysis. On the other hand, excessive humidity (>90% RH) promotes bacterial or fungal overgrowth, increasing the risk of contamination.

Moreover, RH affects not just the microbes but also the physical characteristics of the fermentation substrate. Hygroscopic materials like rice, soybeans, or wheat can absorb or lose moisture rapidly, altering water activity (aw) levels—a key factor influencing microbial competitiveness.

In short, precise control of both temperature and humidity isn’t just about comfort—it’s about biological optimization. Sensors like the HG808-H help maintain these narrow environmental windows, supporting ideal microbial activity and consistent fermentation performance.

Core Monitoring Requirements in Fermentation Facilities

To ensure stable and high-yield fermentation, sensors used in these environments must meet four critical technical demands:

1. Precision & Long-Term Stability

Temperature and humidity control must be highly accurate and stable over time. Even small fluctuations in temperature—say, ±0.5°C—can lead to lower yields or altered metabolite profiles. For industrial-scale fermentation, sensors must deliver:

·High precision (±0.1°C for temperature, ±1.5%RH for humidity)

·Long-term drift resistance to maintain accuracy across extended batches

·Real-time feedback to control systems for prompt adjustments

2. High-Humidity Operation Tolerance

Fermentation rooms and bioreactors often have relative humidity levels exceeding 90%, which poses a serious challenge for conventional sensors.

In such conditions:

·Sensors may become saturated, losing accuracy or failing entirely

·Condensation can damage electronics or give false readings

High RH often coincides with volatile organic compounds like ethanol or acidic gases that increase corrosion risk.

Ideal sensors must be engineered for continuous operation under saturated or near-saturated humidity, with condensation-resistant structures and protective coatings.

3. Flexible Mechanical Design & Installation Options

Fermenters and cleanroom environments vary significantly in structure and layout. A one-size-fits-all sensor cannot meet all needs.

Typical challenges include:

·Limited installation space on fermenter lids or side walls

·Difficult access to measurement points

·Harsh cleaning routines (e.g., steam sterilization, CIP)

Sensors must support:

·Customizable probe lengths and forms

·Flexible mounting methods (threaded, flange, clamp-on)

·Rugged housing that resists mechanical damage and corrosion

4. Signal Output & System Compatibility

Modern fermentation systems are highly automated, integrating SCADA or PLC systems to control all process parameters.

A practical sensor must:

·Support standard signal outputs (4–20 mA, 0–10V, RS485)

·Provide both temperature and humidity data via a single device

·Easily interface with different control systems, reducing installation and maintenance costs

By addressing these core requirements, facilities can optimize fermentation performance, reduce contamination risks, and improve overall production efficiency.

HG808-H: Tailored Solution for Fermentation Environmental Challenges

In fermentation facilities, where temperature and humidity directly influence microbial performance and product quality, environmental monitoring equipment must meet the highest standards. HG808-H Temperature and Humidity Transmitter is specifically engineered to address the exact challenges found in fermentation rooms, bioreactors, and cleanroom environments.

By aligning with the four core monitoring requirements—precision, high-humidity tolerance, mechanical adaptability, and system compatibility—HG808-H ensures stable, accurate, and interference-free environmental control throughout the fermentation cycle.

| Core Requirement | Fermentation Challenge | HG808-H Solution |

| Precision & Stability | Even ±0.5°C variation can alter microbial metabolism and reduce yield | Delivers ±0.1°C temperature accuracy and rapid humidity response, with long-term stability across extended fermentation batches |

| High-Humidity Tolerance | RH >90% leads to sensor drift, failure, or condensation | Robust design supports continuous operation up to 95% RH, with anti-condensation housing and corrosion-resistant sensing elements |

| Mechanical Compatibility | Fermenters vary in structure; limited access, cleaning protocols are strict | Offers 8 sensor probe types with customizable lengths and mounts to fit lids, pipes, walls, or ducts; withstands steam cleaning and chemical exposure |

| Signal Output & Integration | Integrating with PLC/SCADA can be complex and costly | Provides both 4–20 mA and RS485 Modbus output in a single device, enabling seamless plug-and-play into existing control systems |

Additional Advantages for Fermentation Environments

·316L stainless steel housing: Corrosion-resistant and hygienic, ideal for use in acidic, microbial-rich conditions typical of soy sauce, vinegar, and alcohol production.

·Replaceable protective caps: Optional sintered or grid-type filters protect the sensing element from particulates, condensation, and microbial buildup.

·Rapid-response sensors: Captures dynamic shifts in temperature and humidity during batch transitions, improving real-time control and reducing response lag.

With these features, HG808-H isn’t just a transmitter—it’s a process optimization tool designed to help fermentation facilities achieve consistent quality, reduce downtime, and maintain compliance with stringent environmental standards.

Συμπέρασμα

Fermentation is a precise science—and a messy art. While the microbes do the work, it’s the environment that determines success. That’s why investing in accurate, stable, and robust temperature and humidity monitoring is no longer optional. The HG808-H sensor delivers exactly what fermentation facilities need: high performance in high-humidity conditions, flexibility for complex installations, and compatibility with industrial control systems.

Whether you’re producing medicine, enzymes, or traditional foods like soy sauce and vinegar, HG808-H helps ensure every batch reaches its full potential. Contact us at sales@hengkometer.com to learn more about HG808-H.