Introducción

Typically, when we talk about “dew point,” we’re referring to the temperature at which water vapor condenses into liquid water. However, in the natural gas industry, the term “dew point” refers to a different process—the temperature at which hydrocarbons in the gas begin to condense into liquid form. This is known as the hydrocarbon dew point (HCDP).

Have you ever wondered how to measure hydrocarbon dew point? Is it different from the measurement of water punto de rocío? In this article, we’ll dive into how you can measure it to keep your operations running smoothly. Let’s get started.

What is Hydrocarbon Dew Point?

Hydrocarbon Dew Point (HCDP) refers to the temperature at which hydrocarbon gases in a gas stream begin to condense into liquid form under a specific pressure.

Essentially, it’s the temperature at which the gaseous hydrocarbons (like methane, ethane, propane, etc.) in a natural gas or other hydrocarbon-rich gas mixture transition from a vapor phase to a liquid phase.

In simpler terms, it’s the point at which the gas cools enough for the heavier hydrocarbons within it to condense, forming a liquid.

Why it is Immportant?

Hydrocarbon Dew Point is important because once condensation occurs, liquid hydrocarbons can cause issues like pipeline blockages, corrosion, or even compressor damage in natural gas systems.

*Prevents Pipeline Blockages: Condensed liquids can clog pipelines, disrupting gas flow and causing delays.

*Protects Equipment: Liquid hydrocarbons can damage compressors, turbines, and valves, leading to costly repairs.

*Ensures Gas Quality: Accurate HCDP measurement ensures gas meets transportation and usage specifications.

*Enhances Safety: Condensed liquids increase the risk of leaks and explosions, so controlling HCDP improves safety.

*Improves Efficiency: Keeping gas in vapor phase ensures smoother flow and reduces costly interventions.

Factors Affecting Hydrocarbon Dew Point

Several factors influence the hydrocarbon dew point (HCDP) in a gas system. Understanding these is crucial for accurate measurement and control:

*Gas Composition: The types and concentrations of hydrocarbons (e.g., methane, ethane, propane) directly affect the dew point; heavier hydrocarbons lead to higher HCDP.

*Pressure: As pressure increases, the HCDP rises because gas molecules are compressed, making condensation more likely.

*Temperature: Cooler temperatures bring the gas closer to its dew point, increasing the chance of condensation.

*Impurities in the Gas: Non-hydrocarbon components like water vapor or carbon dioxide can alter the overall dew point.

*Flow Conditions: Variations in flow rate and turbulence can impact heat transfer and gas stability, influencing the dew point

The Different Between Water and Hydrocarbon Dew Point Measurement

Measuring the dew point of water and hydrocarbon compounds involves similar principles but has distinct considerations due to the differences in their chemical and physical properties.

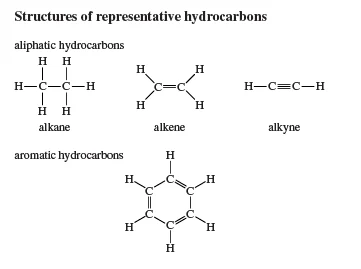

1.Chemical Composition: Water (H₂O) is a polar molecule with strong hydrogen bonding capabilities.

Hydrocarbons range from simple, non-polar molecules like methane (CH₄) to complex mixtures found in crude oil.

2.Dew Point Temperature: Water has a relatively high dew point around 100°C (212°F) under standard atmospheric pressure.

Hydrocarbons, especially lighter ones like methane and ethane, have much lower dew points, often below 0°C (32°F).

3.Measurement Sensitivity: Water’s dew point is more sensitive to temperature changes due to its polar nature.

Hydrocarbons can have dew points that are less sensitive to temperature variations, depending on their specific compound.

4.Environmental Impact: Water’s dew point is significantly affected by relative humidity and is a key factor in climate and weather forecasting.

Hydrocarbon dew points are more influenced by the presence of other gases and the overall composition of the gas mixture.

5.Safety Concerns: Water’s dew point measurement is generally safe and straightforward.

Hydrocarbon measurements, especially for lighter gases, require caution due to flammability and the need for explosion-proof equipment.

While the measurement of the dew point for water is relatively straightforward, the process becomes significantly more complex when it comes to hydrocarbon compounds. Advanced techniques and specialized instruments make it possible to accurately measure hydrocarbon dew point despite these challenges. In the next section, we will guide you through the various methods used for hydrocarbon dew point measurement.

How to Measure Hydrocarbon Dew Point

Measuring the Hydrocarbon Dew Point (HCDP) is a crucial step in ensuring gas systems run efficiently and safely. Here’s a guide to the most common methods used:

1. Chilled Mirror Method

-A gas sample is introduced into the chilled mirror device.

-The mirror is gradually cooled while monitoring for hydrocarbon condensation.

-Once condensation is detected, the corresponding temperature is recorded as the HCDP.

The chilled mirror method is widely used because it offers high accuracy and provides a direct measurement of hydrocarbon condensation, making it suitable for both field and laboratory environments.

It is best for applications requiring precise measurements and for calibrating other dew point measurement devices.

2. Hydrocarbon Dew Point Analyzers

-Gas is drawn into the analyzer, where optical or thermal sensors monitor for condensation.

-The device automatically adjusts temperature to pinpoint the dew point.

-Results are displayed in real-time with minimal operator intervention.

Hydrocarbon dew point analyzers are highly reliable for industrial applications because they provide automated, real-time monitoring with minimal operator intervention. They are best suited for continuous monitoring in gas processing plants or pipelines.

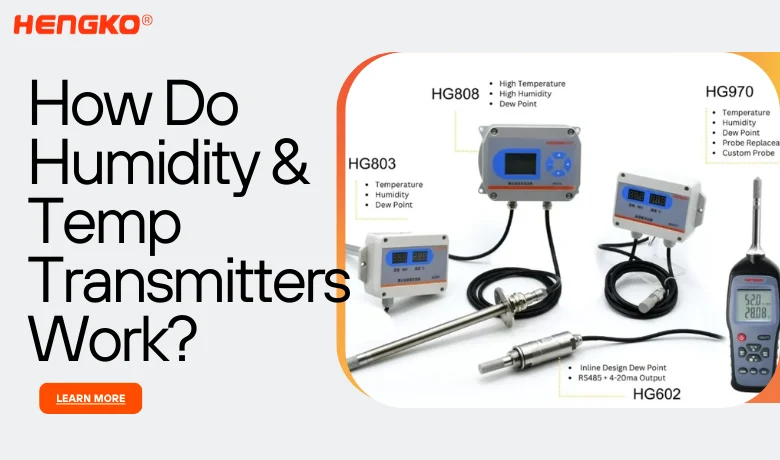

3.Sensor de punto de rocío en línea

HENGKO Temperature and Humidity Transmitter Data Logger Module is a prime example of an advanced dew point detection system. It integrates a high-precision temperature sensor with a humidity sensor, enabling real-time dew point calculations. Features of data loggers like this include:

Data Recording and Storage: Continuously monitors and stores dew point readings, offering valuable insights into trends and fluctuations.

Alarm Functions: Allows for programmable alarms that activate when dew point levels fall outside the desired range, facilitating proactive maintenance and preventing potential problems.

Remote Monitoring: Enables remote access to dew point data for centralized monitoring and analysis, enhancing operational efficiency.

HENGKO offers a wide range of Dew Point Monitoring Solutions, including options like Inline Dew Point Transmitters, Handheld Dew Point Meters, Wall-Mount Dew Point Transmitters, and High-Temperature Dew Point Transmitters, allowing you to choose the best fit for your needs.

4. Gas Chromatography and Thermodynamic Calculations

-A gas sample is analyzed using a gas chromatograph to determine its exact hydrocarbon composition. Involves passing the gas through a column packed with a stationary phase.

-The results are fed into thermodynamic models or software (e.g., Peng-Robinson Equation) to calculate the HCDP.

This method is favored for its ability to deliver detailed compositional analysis and highly accurate dew point calculations. It is ideal for analyzing complex gas mixtures or when detailed gas analysis is required.

5. Thermoelectric Dew Point Hygrometer:

-Utilizes a thermoelectric sensor to detect the temperature change at condensation.

-The sensor generates an electrical signal proportional to the temperature, which is monitored for dew point detection.

Hygrometers are a practical choice because they are simple, cost-effective, and easy to integrate into existing systems. They are most suitable for applications where approximate dew point readings are sufficient.

Tips for Accurate Measurement:

Ensure Clean Sampling: Contaminants like water or oil can interfere with HCDP readings.

Calibrate Equipment: Regular calibration ensures consistent and precise measurements.

Consider Pressure: Always measure HCDP at operating pressure, as dew point varies with pressure.

Monitor Regularly: Continuous monitoring helps detect changes in real-time and prevent system issues.

Conclusión

In summary, measuring the hydrocarbon dew point requires a combination of advanced techniques and specialized tools, such as gas chromatography, chilled mirror devices, or dedicated dew point analyzers. Each method offers unique advantages depending on the application, whether for real-time monitoring, high-precision lab analysis, or field measurements.

Although the process can be complex due to the variability of hydrocarbon mixtures, these methods provide reliable solutions for ensuring gas quality and system safety. By selecting the right approach, you can effectively manage hydrocarbon dew point challenges in your operations.