¿Por qué siguen fallando los sensores genéricos en entornos de cadena de frío?

Because they simply aren’t built for it.

Cold chain logistics demand precision, durability, and rapid response—qualities most off-the-shelf temperature and humidity sensors just can’t deliver. From ultra-low temperatures and condensation to vibration during transit, the cold chain puts sensors to the test. And when they fail, the consequences can be costly: spoiled vaccines, rejected shipments, or compromised food safety.

In this blog, we’ll explore why generic sensors often fall short, the hidden risks of inaccurate readings, and how choosing the right industrial-grade sensor or transmitter can protect your products—and your reputation.

👉 If you’re responsible for cold chain monitoring, this article could save your next shipment.

Introducción

When it comes to cold chain logistics, product safety hinges on more than just temperature. As storage environments grow more complex and goods more sensitive, humidity control has become equally critical. From biopharmaceuticals to perishable foods, maintaining optimal humidity levels is essential to prevent spoilage, ensure efficacy, and preserve packaging integrity.

Yet many cold chain systems still rely on generic sensors that struggle under sustained high humidity—leading to unreliable data and increased operational risks. In this article, we’ll explore the hidden challenges of humidity in the cold chain—and how advanced solutions like the HG808-H Series are engineered to deliver stable, accurate monitoring even in extreme conditions.

Why Humidity Matters in the Cold Chain

When we think about cold chain logistics, temperature usually takes center stage. But humidity—often the invisible factor—can be just as damaging. In many cold storage and transportation scenarios, uncontrolled humidity can lead to moisture buildup, condensation, and even microbial growth. These conditions can compromise product quality long before temperature thresholds are breached.

For pharmaceuticals, excessive humidity can degrade active ingredients, affect shelf life, or cause clumping in powders. In the food industry, high humidity encourages mold growth, alters texture, and weakens packaging integrity. Even paper-based labels or cardboard boxes may lose adhesion or strength under sustained moisture exposure.

Maintaining precise humidity levels isn’t just about product appearance—it’s about safety, compliance, and performance. In regulated industries, consistent humidity data is critical for audits, traceability, and meeting strict quality control standards.

The Hidden Challenges of Monitoring Humidity

Despite its importance, humedad is one of the most difficult environmental factors to monitor accurately—especially in cold chain settings. Many conventional sensors are not built to withstand the harsh, moisture-heavy conditions commonly found in cold storage and transport environments.

One of the biggest challenges is sensor drift. In high-humidity environments (often exceeding 90% RH), many sensors begin to lose accuracy over time. Exposure to condensation, frost, or even brief water ingress can cause readings to fluctuate or fail entirely. This compromises data reliability and increases the risk of undetected deviations.

Another issue is slow response time in low-temperature, high-humidity environments. When condensation forms on sensor surfaces, it can interfere with measurement or delay response, leaving a dangerous blind spot in critical control systems.

And let’s not forget corrosion—a constant threat in humid environments, especially where metallic components or exposed electronics are involved. Without proper protection, sensor lifespan drops drastically, leading to frequent replacements and maintenance costs.

Simply put, not all humidity sensors are created equal. In demanding cold chain conditions, using the wrong sensor can be worse than using none at all.

So how can businesses overcome these challenges? The key lies in using sensors that are purpose-built for the demands of the cold chain—devices that go beyond generic specifications to deliver consistent performance where it matters most. That’s where HENGKO HG808-H High- humidity Series comes in.

Why Standard Sensors Fall Short

Most general-purpose sensors are simply not built for prolonged exposure to extreme humidity. When operating in environments where relative humidity often exceeds 95%—as is common in ripening chambers, cold storage units, or refrigerated transport—standard sensors begin to show their limitations:

·Condensation Build-up: Ordinary sensors often experience signal drift or outright failure when water vapor condenses on their surfaces. This leads to false readings and unreliable data.

·Saturation and Lag: In high-humidity conditions, typical sensors can become saturated, causing sluggish response times and delayed detection of environmental changes.

·Sensor Corrosion: Exposure to moisture, especially in combination with organic vapors or cleaning agents, accelerates material degradation in conventional sensing elements.

·Frequent Calibration and Replacement: To compensate for their instability, standard sensors may require frequent recalibration or even early replacement—adding cost and complexity to cold chain operations.

Poor Integration with Cold Chain Systems: Many general sensors lack industrial-grade communication protocols or the precision needed for compliance with regulatory standards in pharmaceuticals and food logistics.

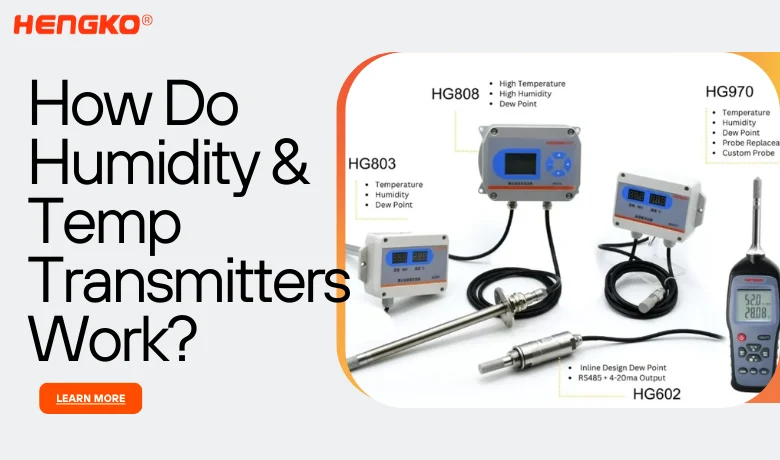

HG808-H: Engineered for High-Humidity Performance

Designed specifically for harsh, high-humidity environments, HG808-H Series stands out where ordinary humidity sensors fail. It combines advanced sensing technology with rugged engineering to deliver accurate, stable performance in even the most challenging cold chain conditions.

At the core of the HG808-H is a high-precision, industrial-grade humidity sensor that resists drift and degradation even in environments exceeding 95% RH. Its specially designed probe structure helps prevent condensation buildup and ensures fast response times—even in low-temperature or humid shock scenarios.

Key Specifications at a Glance:

Humidity Range: 0–100% RH (Recommended for <95% RH continuous use)

Humidity Accuracy: ±2% RH (@23°C, 40–95% RH)

Temperature Range: -40°C to +100°C

Temperature Accuracy: ±0.1°C (@23°C)

Long-Term Stability: <±0.1°C/year (Temp), <±1% RH/year (Humidity)

Pressure Resistance: Up to 16 bar

Output Signals: 4–20mA / 0–5V / 0–10V + RS485 dual signal output

Probe Options: 6 customizable probe types for different installation needs

Las características clave incluyen:

·Condensation-resistant design: Engineered to continue monitoring accurately even during water vapor saturation and condensation events.

·Estabilidad a largo plazo: Maintains reliable readings over extended periods, reducing maintenance frequency and calibration needs.

·Dual-parameter output: Measures both temperature and humidity simultaneously, enabling comprehensive environmental control.

·Rugged, corrosion-resistant housing: Withstands cold storage environments, chemical exposure, and physical stress.

HG808-H Series also supports seamless integration into data loggers, PLC systems, and remote monitoring platforms, making it ideal for real-time alerts, audit trails, and automated compliance reporting.

In short, it’s more than just a sensor—it’s a specialized tool built to ensure product safety, process integrity, and peace of mind in critical cold chain applications.

Application Scenarios: Where the HG808-H Shines

HENGKO HG808-H Series isn’t just built to survive harsh environments—it’s designed to thrive in them. From production floors to transportation vehicles and storage facilities, this sensor series proves its value across a wide range of cold chain applications.

Here are some of the most impactful use cases:

·Pharmaceutical Cold Storage

In vaccine warehouses or biopharmaceutical freezers, precise humidity monitoring is critical for product efficacy and regulatory compliance. HG808-H ensures data stability even during door openings or power fluctuations that often trigger condensation events.

·Refrigerated Transport

Whether it’s a refrigerated truck crossing humid coastal regions or a container ship holding temperature-sensitive biologics, HG808-H withstands both motion and moisture, delivering consistent real-time environmental data.

·Fresh Produce Distribution Centers

In environments where ripening gases like ethylene are present, excess humidity can accelerate spoilage. HG808-H enables early detection of humidity spikes, helping operators make fast adjustments to protect product quality.

·Meat and Seafood Cold Rooms

These spaces often experience extreme humidity due to frequent washing and cleaning processes. The sensor’s corrosion-resistant design allows for long-term deployment without degradation.

·Research Labs and Environmental Chambers

For precision experiments and long-term sample preservation, consistent humidity and temperature readings are non-negotiable. The HG808-H delivers both, with high resolution and stability over time.

Whether it’s monitoring a single walk-in cooler or an entire fleet of reefer trucks, the HG808-H Series helps ensure environmental control remains reliable, automated, and audit-ready.

Final Thoughts: Future-Proofing the Cold Chain with Reliable Humidity Monitoring

In today’s high-stakes cold chain environments, temperature monitoring alone is no longer enough. As products grow more sensitive and regulations more stringent, humidity control has become a critical factor in ensuring safety, quality, and compliance.

Yet traditional sensors often fall short—failing to provide the reliability needed in high-humidity, low-temperature conditions. The HG808-H Series changes that. With its robust design, high-accuracy sensing, and seamless integration capabilities, it empowers operators to maintain full environmental control across every stage of the cold chain.

Whether you’re safeguarding life-saving pharmaceuticals or extending the shelf life of perishable foods, investing in a humidity monitoring solution that’s built for the challenge isn’t just smart—it’s essential.

Ready to elevate your cold chain monitoring? Discover how the HG808-H Series can help you achieve greater precision, lower risk, and full regulatory confidence.

Conclusión

In cold chain logistics, humidity isn’t just a background variable—it’s a real risk. From spoilage and corrosion to regulatory headaches, uncontrolled moisture can quietly undermine even the best-designed systems.

That’s why using the right tools matters. HENGKO HG808-H Series is built for exactly these challenges: stable, accurate, and resistant to the kind of environments that leave standard sensors struggling.

No over-engineering. No marketing fluff. Just a reliable humidity monitoring solution that does its job—consistently, even when conditions are anything but ideal.

Curious if the HG808-H fits your cold chain setup? Get in touch at sales@uHPLCs.com with our team for specifications, integration options, or sample testing—we’re here to help.