Humidity measurement is relatively straightforward at ambient conditions. Most standard sensors perform adequately in offices, warehouses, and general HVAC environments. However, once temperatures rise above conventional limits, humidity measurement becomes a fundamentally different challenge.

In high-temperature industrial processes—such as drying, curing, sintering, baking, sterilization, or flue gas handling—standard humidity sensors frequently fail. These failures are not incidental; they stem from inherent design and material limitations that were never intended for sustained thermal stress.

This article explains why standard humidity sensors struggle or fail in high-temperature environments, what failure mechanisms are most common, and why industrial-grade solutions are essential for reliable process control.

High-Temperature Humidity Measurement Is a Different Problem

At elevated temperatures, humidity measurement is no longer just about sensing moisture—it becomes a combined challenge of:

- Thermal stress on sensing materials

- Accelerated aging and drift

- Condensation and re-evaporation cycles

- Chemical exposure and particulate contamination

- Mechanical expansion and pressure fluctuations

Standard sensors are typically designed for comfort monitoring or light industrial use, often rated for intermittent exposure rather than continuous operation at high temperatures. When pushed beyond these boundaries, performance degrades rapidly.

1. Sensor Materials Degrade Under Sustained Heat

Most standard humidity sensors rely on polymer-based capacitive elements. While cost-effective and responsive at moderate temperatures, these materials are highly sensitive to heat.

Under sustained high-temperature exposure, polymer sensing layers may:

- Lose elasticity and absorbency

- Experience irreversible structural changes

- Become less responsive to moisture variations

- Permanently shift calibration characteristics

This degradation does not always cause immediate failure. Instead, sensors may continue operating while silently delivering inaccurate data—arguably the most dangerous failure mode in industrial environments.

2. Temperature-Induced Drift Overwhelms Compensation Algorithms

Humidity measurement depends heavily on accurate temperature compensation. Standard sensors typically apply compensation models optimized for a narrow temperature range.

In high-temperature environments, these models often break down due to:

- Non-linear temperature–humidity interactions

- Rapid temperature fluctuations during heating or cooling cycles

- Thermal gradients across the sensing element

As a result, readings may drift progressively over time or fluctuate unpredictably with temperature changes. Recalibration offers only temporary relief, as the underlying thermal stress continues to affect sensor behavior.

3. Condensation Cycles Cause Permanent Sensor Damage

High-temperature processes often involve steam, saturated air, or rapid temperature transitions. During shutdowns, startups, or load changes, condensation can form on sensor surfaces—even if the process itself is “hot.”

Standard sensors are rarely designed to survive repeated condensation events. Common consequences include:

- Sensor saturation and delayed recovery

- Water ingress into sensitive electronics

- Corrosion of internal components

- Irreversible damage to sensing layers

Once exposed to repeated condensation cycles, many standard sensors never return to their original accuracy—even if they appear functional.

4. Mechanical and Structural Limits Are Exceeded

Beyond the sensing element itself, standard sensors often lack the mechanical robustness required for harsh environments.

Typical weaknesses include:

- Plastic housings that soften or deform at high temperatures

- Seals and gaskets that degrade under heat

- Inadequate protection against vibration or pressure changes

- Poor resistance to thermal expansion and contraction

In applications such as kilns, ovens, or exhaust ducts, these limitations can lead to premature mechanical failure or unstable readings caused by internal stress.

5. Chemical and Particulate Exposure Accelerates Failure

High-temperature industrial air is rarely clean. It may contain:

- Oil vapors and aerosols

- Process chemicals or solvents

- Combustion byproducts

- Fine particulates or dust

At elevated temperatures, chemical reactions accelerate, increasing the risk of sensor fouling or corrosion. Standard sensors typically lack:

- Protective sintered filters

- High-temperature-resistant probe materials

- Designs that isolate sensitive components from contaminants

Over time, contamination alters sensor response and increases maintenance frequency—or leads to complete sensor failure.

6. Limited Operating Temperature Ratings Are Often Misunderstood

Many standard sensors list maximum temperature ratings that apply only to:

Short-term exposure

Storage conditions

Non-operating states

Continuous operation near or above these limits dramatically shortens sensor lifespan. In contrast, industrial high-temperature humidity transmitters are engineered specifically for continuous duty, with materials, electronics, and housings designed to tolerate prolonged thermal exposure.

7. Data Reliability Suffers Before Sensors Fail Completely

One of the most critical issues is that data quality often degrades long before a sensor stops working.

Symptoms include:

Gradual baseline drift

- Increased noise or signal instability

- Reduced repeatability between measurements

- Inconsistent readings between identical sensors

In process industries, unreliable humidity data can lead to:

Incomplete drying or over-drying

Product quality variation

Increased energy consumption

Unplanned downtime or rework

The cost of poor data often far exceeds the cost of the sensor itself.

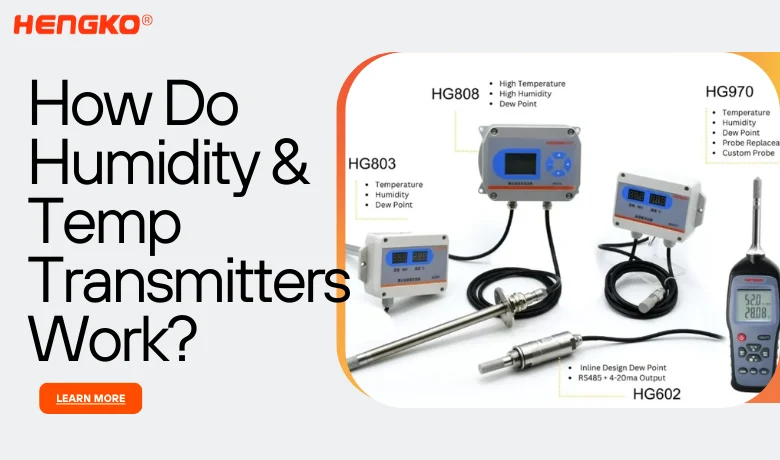

Why Industrial-Grade High-Temperature Humidity Transmitters Exist

High-temperature humidity measurement requires purpose-built solutions. Industrial-grade transmitters differ from standard sensors in several critical ways:

High-temperature-resistant sensing materials designed to maintain stability

Advanced thermal compensation across wide operating ranges

Robust mechanical design for harsh, vibrating, or pressurized environments

Protective probe structures and filters for contaminated gas streams

Signal outputs suitable for control systems, such as 4–20 mA or digital protocols

Most importantly, they are designed for long-term, continuous operation, not occasional exposure.

Typical Applications Where Standard Sensors Fail

High-temperature humidity measurement challenges are common in industries such as:

- Industrial drying and curing ovens

- Ceramic and metal sintering furnaces

- Kilns in building materials and ceramics

- Food and pharmaceutical thermal processing

- Flue gas and exhaust monitoring

- Textile and paper drying systems

In these environments, standard sensors frequently experience shortened lifespans and unreliable performance, prompting frequent replacements and recalibration cycles.

Selecting the Right Solution for High-Temperature Environments

When choosing a humidity measurement solution for high-temperature applications, key considerations include:

- Maximum continuous operating temperature

- Resistance to condensation and steam exposure

- Long-term drift characteristics

- Mechanical durability and probe design

- Integration with existing PLC or control systems

- Maintenance and calibration requirements

Evaluating sensors based solely on upfront cost often leads to higher total cost of ownership when failures and downtime are considered.

結論

Standard humidity sensors are not inherently “bad”—they are simply designed for different conditions. When exposed to sustained high temperatures, aggressive environments, and continuous industrial operation, their limitations become unavoidable.

High-temperature humidity measurement demands specialized engineering, materials, and design philosophy. Understanding why standard sensors fail is the first step toward selecting reliable instrumentation that protects process stability, product quality, and operational efficiency.

For industrial applications where temperature, humidity, and reliability intersect, choosing the right measurement technology is not an upgrade—it is a necessity.