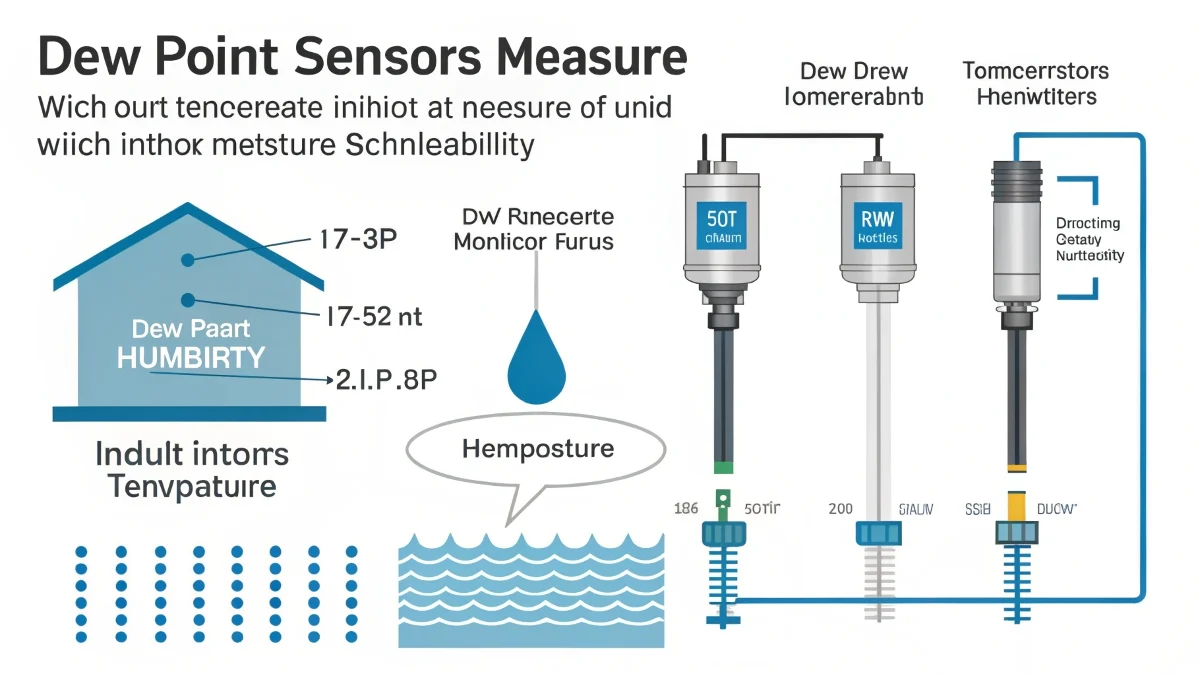

Are you grappling with how dew point sensors impact industrial efficiency? These sensors play a crucial role in maintaining environmental control, preventing corrosion, and ensuring product quality across various sectors.

Dew point sensors work by measuring humidity through different techniques to detect the temperature at which air moisture condenses into liquid. This temperature, known as the dew point, is essential for effective humidity management in industries.

The significance of dew point temperature becomes clear when considering its role in industrial processes. Without proper dew point control, components risk facing corrosion, mechanical failure, and pollution. Real-time monitoring helps manage humidity and improves product quality.

Types of Dew Point Measurement Techniques: What Works Best?

Struggling to find the optimal dew point measurement method? Selecting the right type is vital. Chilled mirror hygrometers, capacitive sensors, and resistive sensors are commonly used methods in industry.

1. How Chilled Mirror Hygrometers Work

Chilled mirror hygrometers are renowned for their precision. They utilize a temperature-controlled mirror, reflecting the dew point as moisture condenses. While highly accurate, they require regular maintenance to ensure results are unaffected by contamination.

2. Capacitive Sensors in Action

Capacitive sensors offer rapid responses by assessing dielectric changes due to varying moisture levels. Although not as precise as chilled mirror systems, they are suitable where speed is imperative.

3. Long-term Stability of Resistive Sensors

Resistive sensors provide stability and longevity by altering electrical conductivity as humidity changes. Their stability makes them ideal for environments where extreme precision is not critical, though they offer lower accuracy compared to other sensors.

Understanding different dew point measurement techniques uncovers a system’s strengths and weaknesses. This insight helps during critical operations like drying and refrigeration, mitigating risks of corrosion and mechanical issues.

Why is Dew Point Important in Industry?

Unsure why dew point monitoring is so important? This key parameter impacts several facets of industrial operations, including equipment integrity and energy conservation.

Benefits of Dew Point Control

- Process Safety and Equipment Protection: High moisture levels can lead to corrosion, undermine equipment integrity, and increase maintenance requirements.

- Quality Assurance: Ensures consistency in final products, pivotal in metallurgy, pharmaceuticals, and refineries.

- Energy Conservation: Enables real-time monitoring to promptly shut down dryers, reducing energy consumption.

- Compliance with Specifications: Aligns with international standards for moisture levels in products.

| Benefit | Impact |

|---|---|

| Process Safety | Reduces corrosion and maintenance needs |

| Quality Assurance | Maintains product consistency and purity |

| Energy Conservation | Lowers energy costs by optimizing cycles |

| Standartų laikymasis | Ensures adherence to international specifications |

Energy efficiency emerges through monitoring, allowing for prompt action upon completing drying cycles, thus reducing costs.

Accurate dew point control ensures alignment with international quality standards, guaranteeing products meet specified requirements. Stable moisture levels help prevent undesirable chemical reactions that could affect refining quality.

Challenges in Dew Point Measurement: How Stable is It?

Encountering issues with measurement accuracy and stability? Precision is vital to avoid losses. Industries demand high accuracy, leading to perfecting the technology through diverse measurement instruments worldwide.

Dew Point Meter Applications

A dew point meter determines dew point temperature in air or gas, serving as a vital tool in modern humidity measurement. It’s indispensable in maintaining environmental conditions in workspaces, factories, and labs.

Pressure Swing Adsorption Insights

In pressure swing adsorption systems for oxygen production, critical dew point indices are below -40℃. This shows minimal moisture levels, crucial for system operation and ensuring oxygen purity by avoiding condensation and corrosion.

| Industry | Dew Point Requirement |

|---|---|

| Metallurgy | Precise control to prevent corrosion |

| Pharmaceuticals | Low moisture to avoid agglomeration |

| Refining | Low moisture to prevent unwanted reactions |

| Oxygen Production | Dew point below -40℃ for high purity |

Overcoming these challenges enhances efficiency, ensuring reliable operations and safeguarding investments in both equipment and systems.

Common Questions about Dew Point Sensors Explained

Curious about how dew point sensors compare to other measurement tools? Here’s a breakdown of popular queries about dew point measurements:

Key Differences Between Common Devices

- Hydrometer vs. Hygrometer: Hydrometers assess liquid density, while hygrometers measure air humidity.

- Barometer vs. Hygrometer: Barometers gauge atmospheric pressure, differing from hygrometers that track moisture.

Alternatives for Humidity Checking

- Humidity Measurement Without Hydrometers: Employ weather apps or observe condensation tendencies for effective tracking.

Choosing the most accurate hygrometer requires exploring options based on specific environmental conditions, guaranteeing effective humidity control.

Išvada

Grasping how dew point sensors function is essential. With various techniques suited to distinct industrial needs, these sensors assure efficient operations and quality assurance.