Industrial drying processes—used in pharmaceuticals, food, chemicals, and materials—demand precise control of temperature and humidity. Deviations can lead to product defects, energy waste, or even equipment damage. Using high-temperature humidity and temperature transmitters, such as the HENGKO HG808-T series, allows plant operators to monitor and control drying environments reliably, even under extreme heat and harsh conditions.

This guide explains why monitoring high-temperature drying environments matters, how sensors work, where to install them, and how HENGKO HG808T transmitters integrate with control systems to ensure optimal performance.

Why Monitor Temperature and Humidity in High-Temperature Drying?

Q1: What exactly is being measured?

A: The HG808-T measures air temperature and relative humidity in drying chambers, ovens, and kilns. These parameters directly influence moisture removal efficiency, product consistency, and energy usage.

Q2: What goes wrong if you ignore accurate monitoring?

Accurate temperature and humidity monitoring is critical in maintaining both product quality and operational efficiency. Ignoring it can lead to several issues in your plant:

1. Over-drying or Under-drying

When humidity isn’t properly monitored, materials like ceramics or powders can be damaged. Over-dried products may become brittle, while under-dried ones can result in uneven powders or cracked ceramics. This leads to scrap, rework, and inconsistent product quality. With the HG808-T transmitter, you can detect humidity deviations early, preventing such problems before they impact production.

2.Energy Waste

Without precise monitoring, your system may consume more fuel or electricity than necessary, driving up operating costs. Continuous monitoring with the HG808-T can alert you to elevated baseline temperatures or humidity, helping optimize energy usage and reduce waste.

3.Equipment Stress

Uncontrolled temperatures can cause overheating in coils or lead to fan failures. This results in unexpected downtime and increased maintenance costs. The HG808-T provides early detection through abnormal temperature spikes, allowing you to take corrective action before equipment is damaged.

4.Safety Risks

Inaccurate monitoring can create dangerous conditions such as hot air leaks or condensation dripping, which may lead to fire hazards or other safety incidents. Rapid temperature or humidity excursions detected by the HG808-T serve as an early warning system, helping maintain a safe working environment.

Where to Place Sensors for Effective Monitoring

Where you install your temperature and humidity sensors makes a significant difference in the quality of the data you collect. Each location in the dryer provides unique insights into your process:

1.Dryer Inlet

Installing a sensor at the dryer inlet helps validate incoming air conditions. This allows you to check whether preheaters or humidifiers are functioning correctly, ensuring that the process starts under optimal conditions.

2.Drying Chamber

Placing sensors inside the drying chamber enables core process monitoring. By tracking temperature and humidity in real time, you can maintain precise control over product quality during drying.

3.Dryer Outlet

Sensors at the dryer outlet verify the final product dryness. Monitoring this point helps prevent over-drying or residual moisture, protecting both product integrity and consistency.

4.Exhaust/Vent

Finally, placing sensors at the exhaust or vent provides insights into energy efficiency and safety. Detecting leaks, condensation, or elevated humidity levels at this stage can prevent damage to downstream equipment and optimize overall energy use.

How HG808-T Transmitters Work in High-Temperature Applications

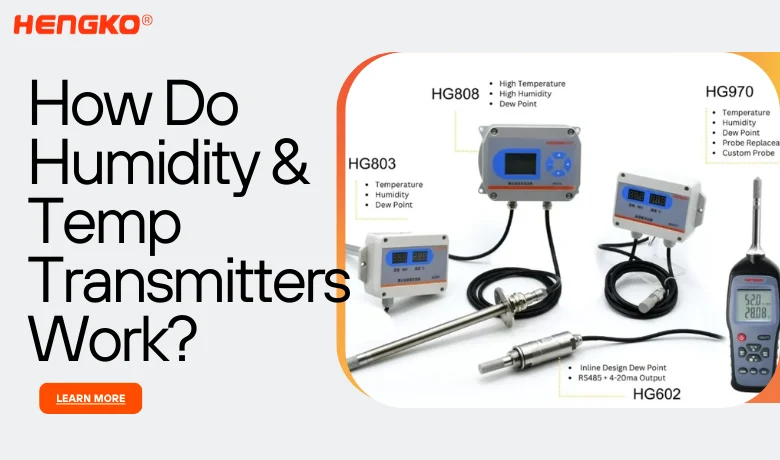

Q1: Which sensor technologies are suitable?

A: HG808-T uses high-temperature capacitive and RTD elements capable of withstanding 40 °C to +200 °C, maintaining ±1% RH accuracy even under industrial stress.

Q2: How are signals processed for industrial use?

- Signal conditioning: Amplifies and linearizes raw sensor output.

- Conversion: Provides 4–20 mA analog and Modbus RTU digital outputs.

- Integration: Connects to PLCs, DCS, or building automation systems for real-time control and logging.

Q3: How do you protect sensors in harsh drying environments?

- Use stainless steel probe housings resistant to heat, corrosion, and dust.

- Install filters or shields to prevent powder deposition or chemical corrosion.

- Leverage modular, replaceable probe heads for quick maintenance without process shutdown.

Using Trends to Optimize Drying Efficiency

Tracking temperature and humidity trends over time gives operators a deeper understanding of the drying process than single-point measurements. Different patterns can indicate specific issues and guide corrective actions:

1.Gradual Humidity Rise

A slow increase in humidity may signal saturated air filters or equipment drift. Operators can respond by inspecting filters and scheduling calibration to maintain consistent drying conditions.

2.Periodic Temperature Spikes

Recurring spikes in temperature often point to fan cycling or heater surges. Adjusting setpoints or tuning PID parameters can help stabilize the process and prevent product quality issues.

3.Sudden Deviations

Abrupt changes in temperature or humidity are usually caused by air leaks or changes in product load. Checking chamber seals and ensuring proper airflow balance helps mitigate these risks.

By actively tracking these trends, operators can prevent over-drying, reduce energy consumption, and extend equipment life, ensuring both efficiency and product quality.

Setting Alarms Without Nuisance Trips

Proper alarm configuration ensures that your system not only detects real issues but also avoids false alarms that disrupt operations.

1. How to Configure Thresholds

Different drying equipment requires tailored alarm settings:

– High-Temperature Oven

The target operating range is 80–180 °C. Set the alarm to trigger on a ±5 °C deviation. Using a 2 °C hysteresis and a 60–120 second delay helps prevent unnecessary trips from minor fluctuations.

– Industrial Kiln

For a kiln operating between 100–200 °C, configure the alarm for a ±7 °C deviation, with a 3 °C hysteresis and a 60–180 second delay. This balances safety with operational stability, reducing false alarms.-

2. How to Respond to Alarms

When an alarm occurs, follow these steps to identify and resolve the issue:

- Inspect air filters and heater coils to ensure they are functioning properly.

- Verify airflow and temperature uniformity throughout the chamber.

- Check calibration and probe condition to ensure accurate readings.

- Document all actions and outcomes for quality assurance and process traceability.

By setting thoughtful thresholds and responding methodically, operators can maintain product quality, protect equipment, and minimize unnecessary downtime.

Specifying HG808-T for Your Application

Q1: What ranges and accuracies should you require?

When selecting temperature and humidity transmitters, it’s important to ensure they cover the full range of your process conditions while providing sufficient accuracy for reliable monitoring:

– Temperature

The transmitter should handle a range from -40 °C to +200 °C, with a minimum accuracy of ±0.5 °C. This ensures precise control across both low- and high-temperature operations.

– Humidity

For humidity measurements, a range of 0–100 % RH is recommended, with a minimum accuracy of ±1 % RH. Accurate humidity readings are crucial to maintaining product quality and preventing over- or under-drying.

By specifying appropriate ranges and accuracies, you can ensure your monitoring system provides trustworthy data for process control and quality assurance.

Q2: Features that reduce lifecycle costs:

- Dual outputs: 4–20 mA + Modbus for control and diagnostics.

- Onboard logging: Root cause analysis and historical audit trail.

- Replaceable probe heads: Minimize downtime.

- IP-rated enclosure: Survive dust, hot air, and washdown cleaning.

Integration and Commissioning

Q1: Inline vs. networked monitoring:

- Inline transmitters provide continuous real-time data at key drying points.

- Networked systems enable plant-wide monitoring, centralized alarms, and energy optimization.

Q2: Calibration and verification: - Commission new transmitters alongside reference meters for 2–4 weeks.

- Schedule periodic checks every 6–12 months, more frequently for dusty or corrosive streams.

Q3: PLC/SCADA integration: - 4–20 mA for analog alarms and control loops.

- Modbus RTU for precise trending, diagnostics, and maintenance alerts.

- On-probe alarms provide failsafe interlocks if the main control system is offline.

Wnioski

In industrial drying and high-temperature processes, controlling temperature and humidity is critical for product quality, energy efficiency, and equipment longevity. HENGKO HG808-T high-temperature humidity and temperature transmitter provides robust, accurate, and continuous monitoring—even under extreme conditions.

By selecting the right sensor, placing it strategically, and integrating it properly, you can prevent product defects, reduce energy waste, and maintain reliable operations.

Optimize your industrial drying process today—contact HENGKO at sales@hengkometer.com to customize an HG808-T solution for your facility.