The Role of Temperature and Humidity Monitoring

Temperature and humidity transmitters are essential tools for modern dehumidification systems, providing real-time data on environmental conditions. By continuously monitoring ambient humidity and temperature, these sensors enable dehumidifiers to operate intelligently and maintain optimal environmental conditions within enclosed spaces, such as warehouses, laboratories, server rooms, storage facilities, or museums.

Without precise monitoring, dehumidifiers may operate inefficiently. Over-drying the air not only wastes energy but can also damage sensitive materials, including paper, electronics, and certain industrial components. Conversely, under-drying leaves equipment and products exposed to moisture-related damage, such as corrosion, mold growth, or degradation of raw materials. Advanced monitoring ensures that dehumidifiers respond dynamically to changing environmental conditions, reducing risk while improving operational efficiency.

Enhancing Energy Efficiency

Energy efficiency is a critical consideration for facilities that operate large-scale dehumidification systems. Traditional dehumidifiers often run continuously or on preset schedules, leading to unnecessary energy consumption. Advanced temperature and humidity transmitters allow smart operation by adjusting fan speed, compressor activity, and other parameters based on real-time conditions.

For example, if a warehouse is less humid in the early morning, the dehumidifier can operate at a lower capacity, conserving energy without compromising air quality. As humidity rises during the day, the system automatically ramps up to maintain the target level. This dynamic control not only reduces operational costs but also extends the lifespan of the dehumidifier by preventing constant, high-intensity operation.

Protecting Sensitive Equipment and Products

Many industrial processes, storage environments, and laboratory operations involve materials that are highly sensitive to moisture. Electronics, pharmaceuticals, food products, high-precision machinery, and even archival documents can all be compromised by improper humidity levels.

By integrating reliable temperature and humidity transmitters with dehumidifiers, operators can ensure consistent environmental control. This prevents costly spoilage, equipment corrosion, and operational disruptions. For instance:

In pharmaceutical storage, precise humidity control ensures that active ingredients remain stable, maintaining drug efficacy.

In food warehouses, controlling humidity reduces the risk of mold and extends shelf life.

In electronics manufacturing, stable humidity prevents condensation that can damage delicate components.

Predictive Maintenance and System Reliability

Another significant advantage of temperature and humidity monitoring is its role in predictive maintenance. By tracking environmental trends over time, facility managers can identify potential system inefficiencies or failures before they escalate into costly problems.

For example, a gradual rise in humidity may indicate a failing dehumidifier component, air leakage, or inadequate insulation in the facility. Early detection allows for timely maintenance, reducing downtime and minimizing repair costs. This predictive capability ensures not only operational reliability but also the continuous protection of sensitive materials and equipment.

Data-Driven Control and Remote Monitoring

Modern temperature and humidity transmitters often come equipped with digital interfaces that support data logging, cloud integration, and remote monitoring. This enables centralized management of multiple dehumidifiers across different locations. Alerts can be sent automatically if conditions deviate from the desired range, allowing managers to take immediate corrective action.

For example, a facility manager overseeing multiple warehouses can monitor real-time humidity and temperature readings from a smartphone or computer. Any anomalies trigger instant notifications, ensuring that all environments remain within target ranges—even without physical presence. This data-driven approach improves operational efficiency, reduces human error, and provides actionable insights for long-term planning.

Application Scenarios

Temperature and humidity monitoring is essential across a wide range of industries and facilities:

Industrial Storage: Raw materials and finished goods are protected from moisture damage, reducing losses and maintaining product quality.

Laboratories and Clean Rooms: Controlled conditions are critical for experiments, testing, and production of sensitive products.

Server Rooms and Data Centers: Preventing condensation and high humidity levels protects servers and IT equipment from short circuits and corrosion.

Museums and Archives: Artifacts, documents, and historical items require consistent environmental conditions to prevent degradation.

Pharmaceutical and Food Storage: Maintaining precise humidity ensures product efficacy, safety, and compliance with regulatory standards.

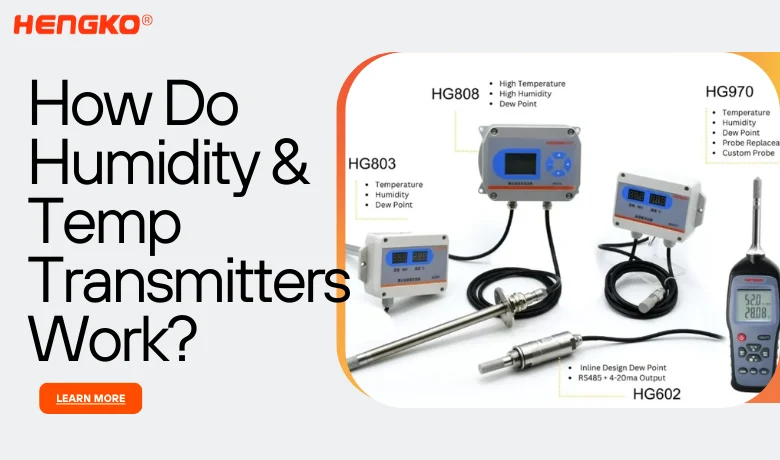

Choosing the Right Sensor

Selecting the appropriate temperature and humidity transmitter is crucial for reliable performance. Key considerations include:

Measurement range and accuracy: Ensures sensors are suitable for the specific environment and required precision.

Response time: Rapid detection allows dehumidifiers to react promptly to changes.

Durability: Sensors must withstand high humidity, temperature fluctuations, and exposure to chemicals or dust.

Output compatibility: Both analog and digital outputs are necessary to integrate seamlessly with existing dehumidifier control systems.

At Hengko, our high-precision transmitters offer robust performance under diverse conditions, providing reliable environmental data to optimize dehumidifier operation and protect valuable assets.

Wnioski

Integrating advanced temperature and humidity monitoring into dehumidifier systems is no longer optional—it is a safeguard for both operational efficiency and material protection. By enabling energy-efficient operation, preventing moisture-related damage, and supporting predictive maintenance, these sensors ensure that dehumidifiers perform at their best.

For industries and facilities where moisture control is critical, leveraging precise environmental data is key to success. Hengko’s high-quality transmitters deliver the accuracy, stability, and reliability necessary to optimize dehumidification systems, making them an essential component of modern moisture control strategies.