HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Strona główna " Portfolio " Przetwornik wysokiej temperatury i wilgotności z krótką sondą śrubową serii HG808-A

The HG808 is a high-performance transmitter that measures dew point, temperature, and humidity in super high-temperature environments reaching +180 °C (356 °F).

With a heat-resistant, waterproof probe and industrial-grade electronics, it ensures reliable and accurate data in drying systems, furnaces, and high-temperature process lines.

Key Features:

Wide Temperature Range: +80 °C to +180 °C (176 °F to 356 °F)

High-Temperature Probe: Dust- and moisture-resistant for long-term stability

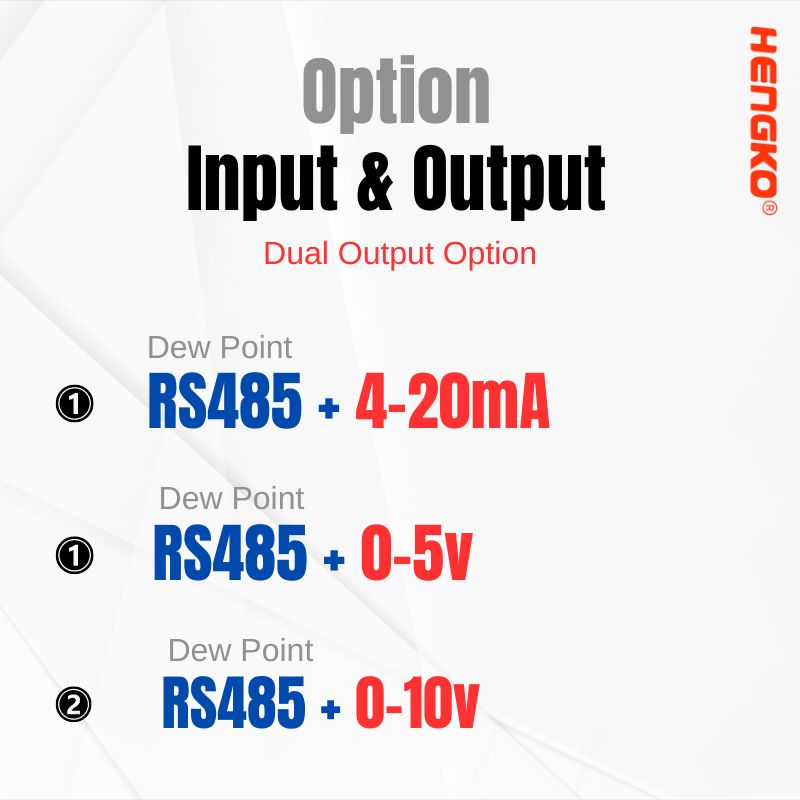

Flexible Outputs: RS-485 (Modbus-RTU), 4–20 mA, 0–5 V / 0–10 V

Integrated Display: Real-time view of dew point, temperature, and humidity

Industrial Integration: Compatible with PLC, DCS, and on-site control systems

Idealny dla:

Drying Ovens | Heat-Treatment Systems | High-Temperature Air or Gas Monitoring

📩 Contact us to configure your high-temperature dew point monitoring solution today.

Here’s a specification details for the HG808-A series Dew Point Transmitter :

| Kategoria | Specyfikacja |

|---|---|

| Zakres temperatur | +80 ~ +180°C |

| Zakres punktu rosy | -20 ~ +100°C |

| Dokładność temperatury | ±0,1°C (PRZY 20°C) |

| Dew Point Accuracy | ±3% RH (± 5.4 °F) Td |

| Zasilanie | DC 10V ~ 28V |

| Zużycie energii | < 0.5W |

| Wyjścia analogowe | Wilgotność + temperatura: 4~20mA / 0-5V / 0-10V (jeden z trzech) |

| Wyjście cyfrowe RS485 | Temperatura, wilgotność, punkt rosy, PPM (odczytywane jednocześnie) |

| Współczynnik rozdzielczości | 0,01°C / 0,1°C (opcjonalnie) 0,01% RH / 0,1% RH (opcjonalnie) |

| Szybkość transmisji | 1200, 2400, 4800, 9600, 19200, 115200 (domyślnie: 9600 bps) |

| Częstotliwość pozyskiwania | Najszybsza reakcja: 1 sekunda; inne ustawienia wg PLC |

| Format bajtów | 8 bitów danych, 1 bit stopu, brak kontroli |

| Ciśnienie | 16 bar |

| Temperatura pracy | -20°C ~ +60°C, 0% RH ~ 95% RH (bez kondensacji) |

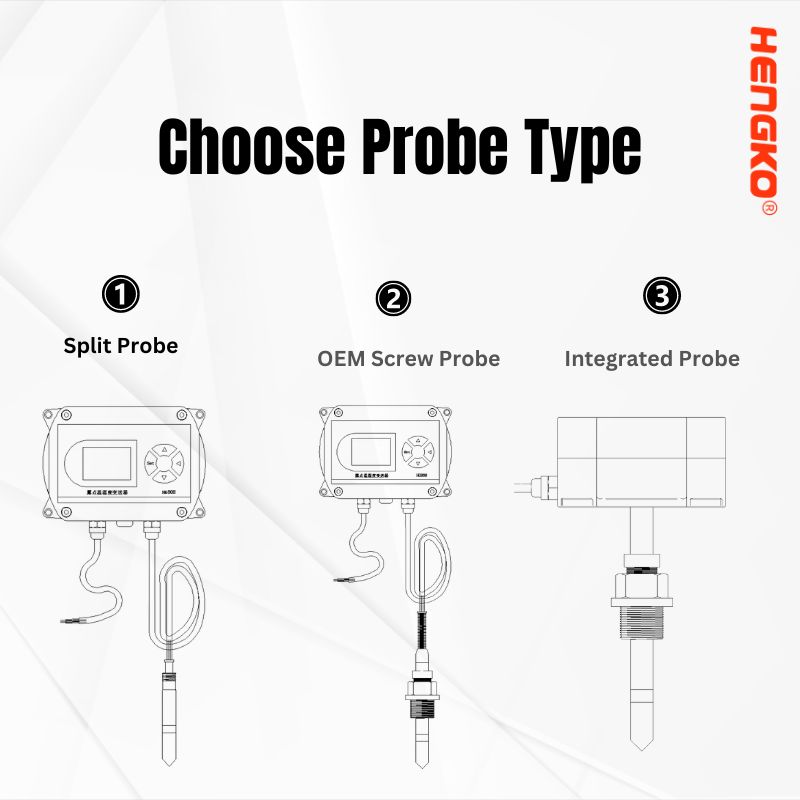

| Typ sondy | Typ podziału: Sonda 0 -Typ dzielony : 0A# / 0B# Probe 8 –Split type :8A# / 8B# |

Oferujemy 6 typów sond do przetwornika wilgotności HG808, przy czym każdy typ jest dostępny zarówno w wersji A, jak i B, zapewniając łącznie 12 sond do różnych zastosowań.

0A#

1A#

3A#

5A#

6A#

8A#

0B#

1B#

3B#

5B#

6B#

8B#

Złącze sondy ze stali nierdzewnej z gwintem sześciokątnym M20

G1/2 Złącze sondy ze stali nierdzewnej z gwintem sześciokątnym

NTP1/2 Złącze sondy ze stali nierdzewnej z gwintem sześciokątnym

Złącze sondy ze stali nierdzewnej z gwintem sześciokątnym M27

Złącze sondy M20 z kołnierzem ze stali nierdzewnej

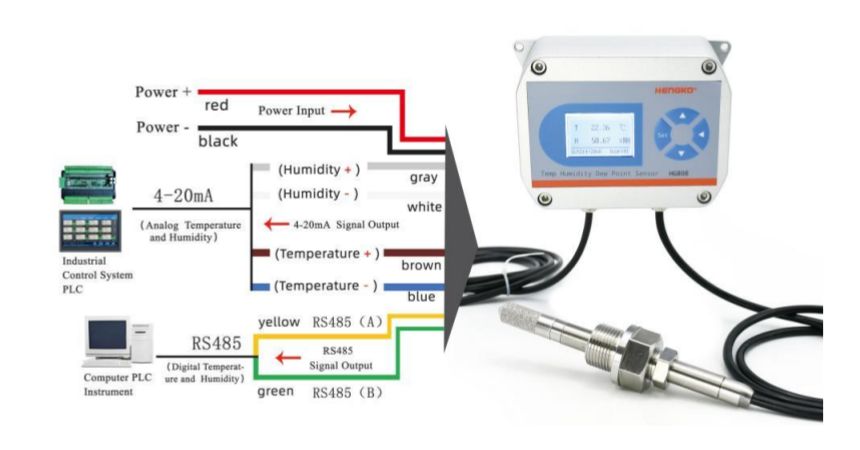

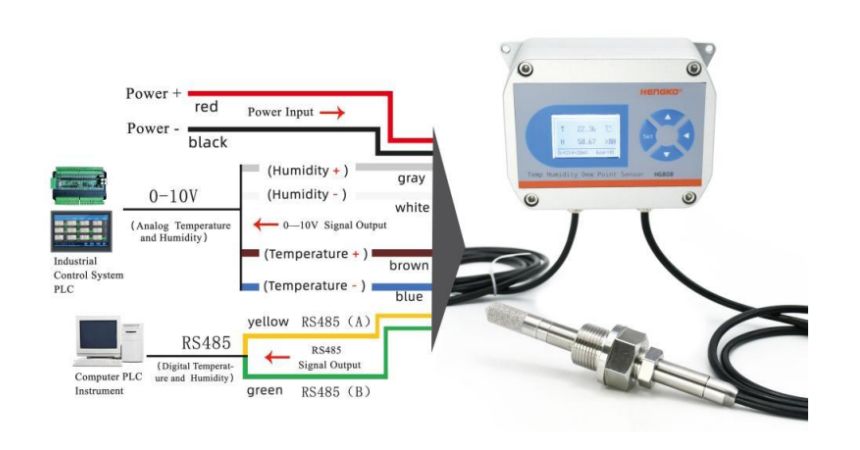

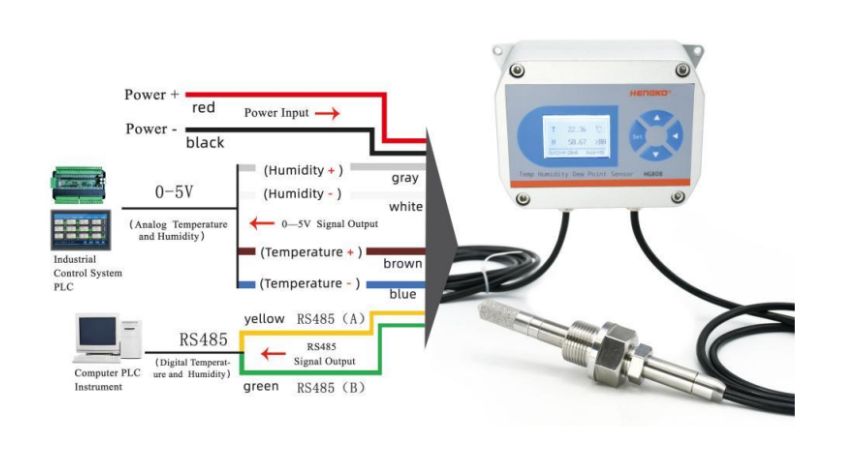

| Kolor linii | Definicja | Specyfikacja |

|---|---|---|

| Przewód zasilający | ||

| Czerwony | Zasilanie dodatnie | 10 ~ 30 V DC |

| Czarny | Zasilanie ujemne | GND |

| Linie wyjścia analogowego | ||

| Brązowy | Dodatni sygnał temperatury | Wyjście 4-20 mA |

| Niebieski | Ujemny sygnał temperatury | Łączy się z czarnym (GND) |

| Szary | Sygnał wilgotności dodatni | Wyjście 4-20 mA |

| Biały | Ujemny sygnał wilgotności | Łączy się z czarnym (GND) |

| Okablowanie RS485 | ||

| Żółty | RS485A | Kabel typu skrętka |

| Zielony | RS485B | Kabel typu skrętka |

Dodatkowe uwagi:

Ważne:

Industrial processes often involve extreme temperatures and humidity levels. Regular transmitters can’t handle these harsh conditions. Here’s a breakdown of applications where high-temperature and humidity transmitters (operating over 200°C and down to -50°C) are crucial:

To tylko kilka przykładów. Przetworniki wysokiej temperatury i wilgotności odgrywają istotną rolę w różnych gałęziach przemysłu, zapewniając kontrolę procesu, jakość produktu i bezpieczeństwo w ekstremalnych warunkach.

2. Zaznacz Wszystkie inne Pliki do pobrania

The HG808 A series ultra-high temperature online dew point meter is designed for humidity measurement in high-temperature and dry environments,

equipped with a sturdy cast aluminum housing and stainless steel sensor components, suitable for continuous and accurate monitoring of temperature

and dew point in extremely harsh high-temperature industrial environments.

The A series ultra-high temperature online dew point meter is equipped with a dew point sensor that can withstand ultra-high temperatures, and also has

online real-time monitoring function.

This product has a wide range of applications, covering multiple fields such as food, medicine, chemical industry, high-temperature drying, and

environmental monitoring.

The HG808-A series is engineered for precise humidity measurement in high-temperature, dry environments.

Key features include:

| Kategoria | Details |

|---|---|

| Product Name | HG808-A Series Ultra-High Temperature Online Dew Point Meter |

| Product Function | Accurate online monitoring of temperature and dew point in high-temperature, dry industrial settings. |

| Construction | – Cast aluminum housing- Stainless steel sensor components |

| Monitorowanie w czasie rzeczywistym | – Online monitoring capabilities- Dew point sensor for ultra-high temperatures |

| Zastosowania | – Food Industry: Ensures product quality in drying ovens (vegetables, fruits, etc.) – Pharmaceutical Industry: Prevents moisture contamination during drying and disinfection – Chemical Industry: Enhances chemical reactions by monitoring dew point to avoid moisture interference – High-Temperature Drying: Improves efficiency and optimizes energy by accurately monitoring gas dew points – Monitorowanie środowiska: Measures combustion flue gas and chimney emissions to comply with environmental standards |

| Corrosion Resistance | Resistant to chemical gases, oil vapor, dust, micro particles; suitable for ultra-high temperature conditions (<190 °C) and corrosive environments |

| Interconnectivity | Modbus RTU protocol; integrates easily with PLC, DCS, and various configuration software |

| Versatile Use | Suitable as accessory in: – High heat process engineering systems- Industrial high-temperature drying systems – High-temperature constant temperature and humidity experimental chambers |

| Customer Support | Alternative products available upon inquiry for specialized measurement needs |

For measurement needs not met by the HG808-A series,

please contact our customer service for alternative temperature and humidity measurement products.

Thank you for your interest!

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Rola monitorowania temperatury i wilgotności Przetworniki temperatury i wilgotności są niezbędnymi narzędziami w nowoczesnych systemach osuszania, dostarczając w czasie rzeczywistym danych o warunkach środowiskowych. Przez

Krótko mówiąc, przetworniki wilgotności i temperatury mierzą i przesyłają dane środowiskowe do systemów sterowania. Są one szeroko stosowane w HVAC, przemyśle farmaceutycznym, przetwórstwie spożywczym i pomieszczeniach czystych

Dlaczego mierniki punktu rosy osuszaczy mają kluczowe znaczenie dla systemów sprężonego powietrza? Być może zawsze walczysz z ukrytą wilgocią w sprężonym powietrzu, która może powodować korozję, zamarzanie,

Dlaczego jedna strefa biurowa jest zbyt wilgotna i jak przetwornik wilgotności może temu zaradzić Utrzymująca się wilgotność w jednej strefie biurowej może zakłócać komfort, zwiększać pleśń i powodować powstawanie pleśni.

Wprowadzenie Sprężone powietrze jest często określane mianem "czwartego medium" w nowoczesnym przemyśle, obok energii elektrycznej, wody i gazu. Jednak jednym z najbardziej powszechnych