HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Accurate Dew Point Monitoring for Corrosive and Chemically Aggressive Environments

The HG808-G is an industrial-grade transmitter for dew point, temperature, and humidity measurement in harsh chemical and solvent environments.

Made from 316L stainless steel with a nano-coated anti-corrosion finish, it ensures long-term accuracy and stability in the presence of acids, alkalis, and salt mist.

Key Features:

*Corrosion-Resistant Build: 316L stainless steel probe with protective coating

*Wide Measuring Range: Dew point −60 °C ~ +20 °C (−76 °F ~ +68 °F)

*High Accuracy: ±3 °C Td dew point, ±0.2 °C temperature

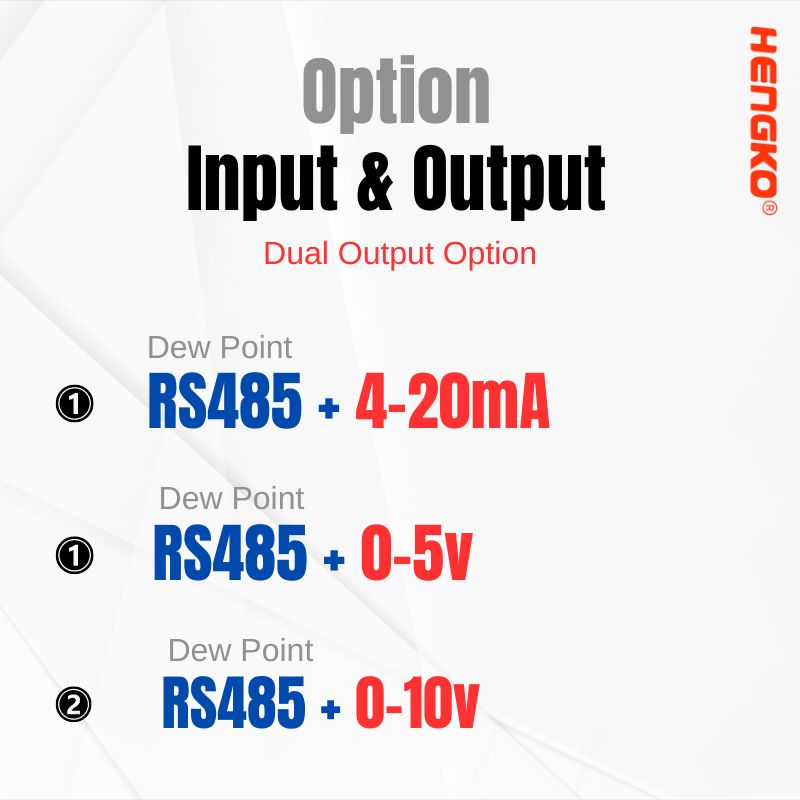

*Flexible Outputs: RS-485 (Modbus-RTU), 4–20 mA, 0–5 V / 0–10 V

*Industrial Protection: IP65 housing, 16 bar pressure resistance

*Fast Response < 1 s: Ideal for real-time process monitoring

*Easy Integration: Connects directly to PLC, DCS, or SCADA systems

Perfeito para:

Chemical | Pharmaceutical | New-Energy | Solvent Recovery Processes

📩 Contact us to configure your corrosion-resistant dew point solution today.

Here’s a specification details for the HG808-G series Humidity Transmitter :

| Categoria | Especificação |

|---|---|

| Measurement Parameters | Dew Point, Temperature, Humidity, PPM (for reference) |

| Faixa de ponto de orvalho | -60 °C ~ +20 °C |

| Precisão do ponto de orvalho | ±3 °C Td (±5.4 °F) |

| Faixa de temperatura | –20 °C ~ +60 °C |

| Precisão de temperatura | ±0,2 °C (A 23 °C) |

| Temperature Long-Term Stability | ≤ 0,1 °C / ano |

| Humidity Long-Term Stability | ≤ 1 % RH / year |

| Saída digital | RS485 (Modbus-RTU); outputs temperature, humidity, dew point, PPM (humidity & PPM for reference only) |

| Saídas analógicas | Temperature + Dew Point – select one: 4-20 mA / 0-5 V / 0-10 V |

| Resistência à pressão | ≤ 16 bar |

| Taxa de transmissão | 1200, 2400, 4800, 9600, 19200, 115200 bps (selectable; default 9600 bps) |

| Frequência de aquisição | Fastest response 1 second; adjustable via PLC |

| Working Environment | –20 °C ~ +60 °C; 0 % ~ 95 % RH (non-condensing) |

| Fonte de alimentação | DC 12 V ~ 24 V, reverse-polarity protected |

| Consumo de energia | < 0.5 W |

| Output Protocol | Standard Modbus-RTU; compatible with PLC, DCS, and SCADA systems |

| Construção | Compact aluminum housing with industrial grade ESD & anti-reverse protection |

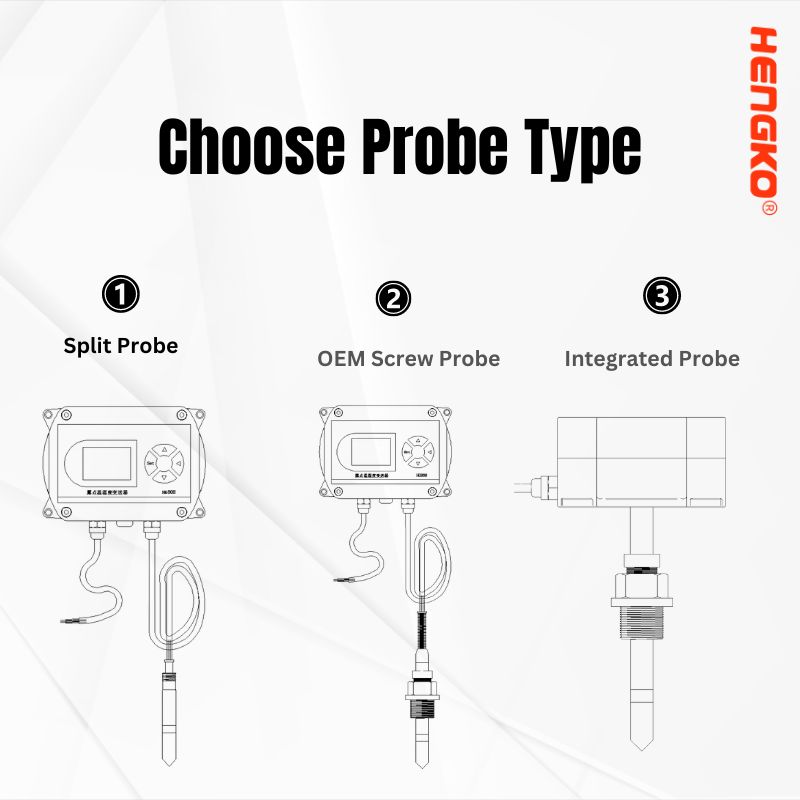

| Installation & Customization | Custom probe design available according to application needs (structure, shape, length, material, mounting method) |

| Protection Rating | IP65 – dustproof and moisture-resistant |

| Applicable Probe Options | Two probe types available: • Gas Sampling Unit • 316L Stainless Steel Sintered Protective Housing (A-Type, 0A# / 8A#) |

Oferecemos 6 tipos de sondas para o Transmissor de Umidade HG808, com cada tipo disponível nas versões A e B, fornecendo um total de 12 sondas para várias opções de aplicação.

0A#

8A#

Conector de sonda de aço inoxidável com rosca hexagonal M20

G1/2 Conector de sonda de aço inoxidável com rosca hexagonal

NTP1/2 Conector de sonda de aço inoxidável com rosca hexagonal

Conector de sonda de aço inoxidável com rosca hexagonal M27

Conector de sonda de aço inoxidável com flange M20

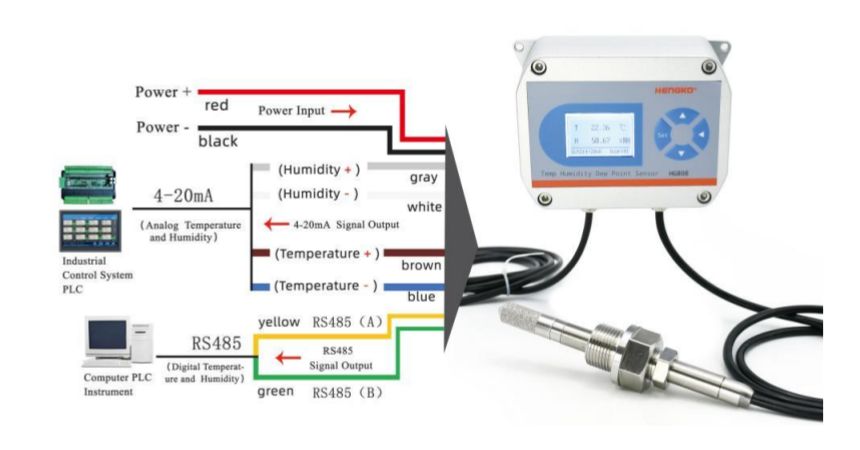

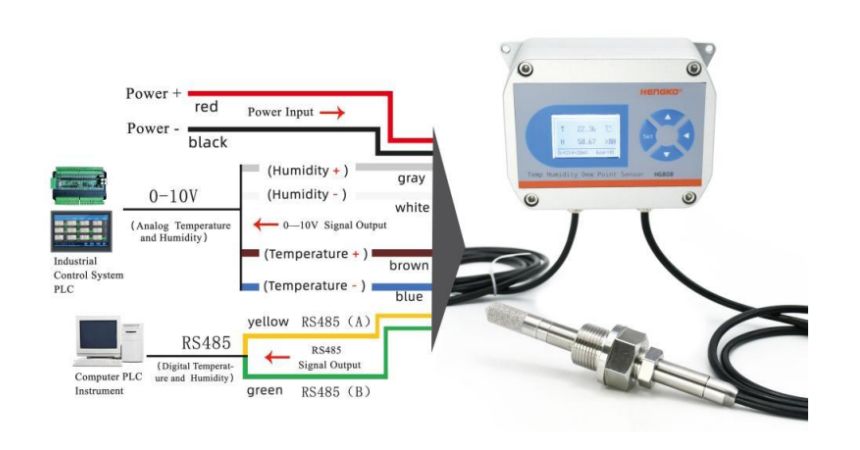

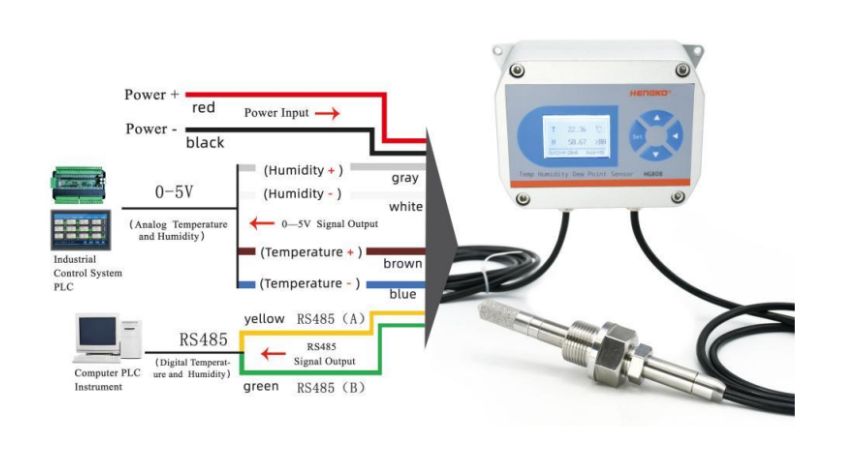

| Cor da linha | Definição | Especificação |

|---|---|---|

| Cabo de alimentação | ||

| Vermelho | Fonte de alimentação positiva | 10 ~ 30V CC |

| Preto | Negativo da fonte de alimentação | GND |

| Linhas de saída analógica | ||

| Marrom | Sinal de temperatura positivo | Saída de 4-20mA |

| Azul | Sinal de temperatura negativo | Conecta-se ao preto (GND) |

| Cinza | Sinal de umidade positivo | Saída de 4-20mA |

| Branco | Sinal de umidade negativo | Conecta-se ao preto (GND) |

| Fiação RS485 | ||

| Amarelo | RS485A | Cabo de par trançado |

| Verde | RS485B | Cabo de par trançado |

Observações adicionais:

Importante:

Precise dew point and humidity monitoring is critical to prevent moisture contamination of electrolyte solutions e ensure uniform electrode coating quality.

Typical conditions: Dew point ≤ –40 °C, temperature 20 – 30 °C, humidity < 1 % RH.

Control requirement: Continuous online dew point monitoring in glove boxes and drying chambers for ultra-low humidity environments.

During chemical synthesis or solvent recovery, excessive moisture can affect reaction yield, purity, and safety. The HG808-G provides stable measurements even in acidic, solvent, or oil-vapor atmospheres.

Typical conditions: Dew point –40 ~ 0 °C, temperature 25 – 60 °C, humidity 5 – 40 % RH.

Control requirement: Corrosion-resistant dew point monitoring under HF, HCl, NH₃, or VOC exposure to prevent condensation and corrosion.

Humidity and temperature stability are essential to maintain API potency and drying uniformity. The HG808-G ensures accurate dew point and temperature control in cleanrooms and drying ovens.

Typical conditions: Dew point –30 ~ +10 °C, temperature 40 – 80 °C, humidity 2 – 20 % RH.

Control requirement: Real-time humidity feedback to optimize drying cycles and ensure GMP-compliant environmental monitoring.

FGD processes involve high-temperature, corrosive gases with varying moisture content. The HG808-G’s 316L stainless-steel probe withstands SO₂/SO₃ and acid mist for long-term reliability.

Typical conditions: Temperature 60 – 120 °C, humidity 10 – 80 % RH, dew point 0 ~ 50 °C.

Control requirement: Dew point monitoring for condensation control and corrosion prevention in gas treatment systems.

Stable dew point monitoring is required to prevent pipeline condensation, corrosion, and particulate accumulation in emission control systems.

Typical conditions: Temperature 30 – 90 °C, dew point –20 ~ 40 °C, humidity 5 – 70 % RH.

Control requirement: Continuous dew point trend tracking to maintain safe moisture levels before gas filtration or catalytic processing.

2. Marque Todos os outros Baixar arquivos

The HG808-G is engineered with an integrated corrosion-resistant structure, using 316L stainless steel and a sealed cast-aluminum housing (IP65). It resists acids, alkalis, electrolyte vapors, and chemical solvents, making it ideal for Baterias de lítio, produtos químicos e farmacêuticos applications where standard sensors fail.

This transmitter has undergone strict testing for oil-gas mixtures, chemical corrosion, and dust impact. Its IP65-rated aluminum enclosure e pressure-resistant 316L probe can withstand up to 16 barras, ensuring long-term stability and reliability even in challenging process environments.

The HG808-G offers flexible signal outputs for easy system integration:

Digital: RS485 (Modbus-RTU) for dew point, temperature, humidity, and PPM values.

Analógico: Dual-channel outputs of 4-20 mA, 0-5 V, or 0-10 V (user selectable).

This design allows seamless connectivity with PLC, DCS, or SCADA systems for automated dew point and temperature control.

Yes. The transmitter includes data-recording functionality and supports connection to backend analysis software. Users can generate reports and trend charts with one click, enabling efficient monitoring, traceability, and process optimization.

The HG808-G can output dew point temperature, process temperature, relative humidity, and PPM values at the same time—providing a complete picture of gas dryness and system conditions.

By integrating advanced sensor technology and optimized circuitry, the HG808-G matches the performance of imported brands at a significantly lower cost. It delivers high precision, strong corrosion resistance, and excellent long-term stability, helping customers reduce maintenance and procurement costs.

Yes. HENGKO offers customized probe designs (structure, length, material, and mounting method) to meet specific process requirements—ensuring accurate and stable dew point measurement under any industrial condition.

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

O papel do monitoramento de temperatura e umidade Os transmissores de temperatura e umidade são ferramentas essenciais para os sistemas de desumidificação modernos, fornecendo dados em tempo real sobre as condições ambientais. Por

Em resumo, os transmissores de umidade e temperatura medem e enviam dados ambientais para sistemas de controle. Eles são amplamente usados em HVAC, produtos farmacêuticos, processamento de alimentos e salas limpas

Por que os medidores de ponto de orvalho do secador são essenciais para os sistemas de ar comprimido? Talvez Você sempre lute contra a umidade oculta no ar comprimido que pode causar corrosão e congelamento,

Por que uma zona de escritório é muito úmida e como um transmissor de umidade resolve isso A umidade persistente em uma zona de escritório pode prejudicar o conforto, aumentar o mofo

Introdução O ar comprimido é frequentemente mencionado como a "quarta utilidade" na indústria moderna, ao lado da eletricidade, da água e do gás. No entanto, um dos problemas mais comuns