Вступ

Glove boxes, also known as inert atmosphere boxes or isolation chambers, play a vital role in laboratories and industrial environments where contamination control is critical. Whether you’re working with lithium battery materials, sensitive organic compounds, or precision semiconductors, maintaining strict environmental control inside the glove box is essential. At the heart of this control is accurate monitoring of three key parameters: temperature, relative humidity, and dew point.

In this article, we’ll explore how temperature and humidity transmitters — especially those capable of dew point detection — are used in glove box applications, what challenges they help solve, and how to select the right monitoring solution to safeguard both processes and products.

What Is a Glove Box?

A glove box is a sealed container designed to create a controlled atmosphere where operations can be performed without direct human contact. Workers interact with materials inside the box via glove ports, which are fixed to the enclosure. Glove boxes are commonly filled with inert gases like nitrogen or argon to displace moisture and oxygen.

Common applications include:

-Lithium battery R&D and production

-Air- and moisture-sensitive chemical synthesis

-Pharmaceutical sterile packaging

-Semiconductor packaging and storage

-Precision material handling (e.g., rare earth metals, catalysts)

In all of these environments, small deviations in temperature, humidity, or dew point can lead to compromised product quality, reduced safety, or failed experiments.

Key Reasons for Monitoring Inside a Glove Box

● Температура

Maintaining consistent temperature inside a glove box ensures stability in chemical reactions, sample integrity, and reliable equipment performance. Fluctuations can cause condensation, pressure changes, or unintended reactions.

● Relative Humidity (RH)

In glove boxes, particularly those working with lithium, moisture must be kept extremely low — often below 1% RH, sometimes as low as 0.1%. Even trace amounts of water vapor can:

-Cause lithium to oxidize or ignite

-Alter chemical structures of moisture-sensitive compounds

-Increase the risk of microbial contamination in pharma settings

● Точка роси

Dew point is a more sensitive and accurate metric than RH in low-moisture environments. It reflects the absolute water vapor content in the gas (measured in °C or ppm). Dew point monitoring is critical in applications requiring ultra-dry atmospheres:

Dew points below -40 °C are often required in glove boxes used for lithium batteries and semiconductors

Dew point measurement provides real-time feedback on inert gas purity and glove box sealing integrity.

How Dew Point Transmitters Work Inside a Glove Box

In glove box environments, maintaining ultra-low humidity is critical, especially in applications involving lithium batteries, pharmaceuticals, or inert atmosphere research. To ensure optimal control, a dew point transmitter is mostly used due to its higher sensitivity in measuring extremely low moisture levels.

For effective monitoring, the transmitter can be installed at different points within the glove box system, each serving a unique role:

• At Position A (gas inlet), the dew point transmitter measures the dryness of the incoming purge gas. This ensures the purification unit is working correctly but does not detect internal leaks or moisture released by materials inside the glove box.

• At Position B (gas outlet), the transmitter detects the humidity of the exhausted gas. It reveals if moisture has entered the system—either from leaks or from materials outgassing—making it ideal for real-time leak detection and process monitoring.

• At Position C (antechamber), the transmitter provides localized moisture readings during sample transfer. However, due to limited airflow, it may not detect moisture from distant leaks or open seals.

For complete protection, combining sensors at multiple locations can provide a more comprehensive view of system integrity.

How to Choose the Right Environmental Transmitter for Your Glove Box

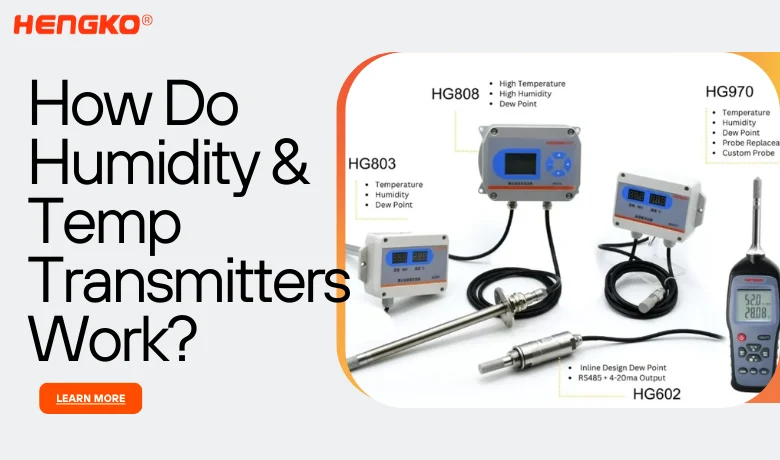

✅ Three-in-One Capability

Choose a transmitter that can measure temperature, relative humidity, and dew point in one unit to simplify installation and maximize data precision.

✅ Wide Measurement Range & High Accuracy

Look for:

RH accuracy: ±1.5% or better

Dew point: capable of -60 °C or lower

Temperature: stable across ±0.2 °C

✅ Industrial Compatibility

Support for standard communication protocols (Modbus, RS485, 4–20 mA) ensures smooth integration into your glove box’s PLC or DCS systems.

✅ Robust Design

Sensors must resist corrosion, dust, and chemicals — especially in reactive gas environments.

✅ Real-Time Feedback & Alarming

Ideal sensors support configurable alarms and quick-response feedback to trigger purging systems or emergency protocols when limits are exceeded.

Highlighting: HENGKO — our compact, precision-engineered transmitter delivers stable readings under ultra-dry conditions, offering reliable data output and seamless system compatibility.

Conclusion: Monitor Smarter, Operate Safer

In moisture-sensitive glove box operations, environmental monitoring is not just a good idea — it’s mission critical. Accurate measurement of temperature, humidity, and dew point ensures process stability, protects sensitive materials, and keeps your operations compliant and safe.

By choosing a high-quality, industrial-grade transmitter tailored to glove box use, you can:

Reduce maintenance and system downtime

Improve product quality and reproducibility

Ensure regulatory compliance and safety

Ready to Upgrade Your Glove Box Monitoring?

Discover our full line of temperature, humidity, and dew point transmitters designed for high-performance glove box applications. Engineered for accuracy, built to last.

Contact us today at sales@hengkometer.com

Learn more at www.hengkometer.com