Вступ

Have you ever wondered how astronauts get to eat delicious food in space? Or how scientists preserve tiny creatures for study? The secret is the machine called freeze dryers.

A freeze dryer (also known as a lyophilizer) is a machine used to remove moisture from sensitive products through freezing and vacuum drying. To ensure optimal results, precise control of temperature and humidity is essential. Temperature and humidity transmitters are key tools in monitoring these factors, providing real-time data to maintain the right conditions.

This article discusses how these transmitters play a key role in the three critical stages of the freeze drying process: freezing, primary drying, and secondary drying.

How Does a Freeze Dryer Machine Work?

The freeze drying process is carried out in three primary stages, each with distinct objectives and conditions:

1. Freezing Stage

Purpose: The product is frozen to transform water content into ice. This is a critical step that sets the foundation for effective drying.

Process: Products are cooled below its freezing point, ensuring complete solidification of water.

The cooling rate determines the size of ice crystals, which affects the efficiency of the subsequent drying stages. Slower freezing produces larger ice crystals, facilitating easier sublimation.

Key control: Temperature must be carefully managed to prevent ice crystals from becoming too large, which can damage the product.

2. Primary Drying Stage (Sublimation)

Purpose: Ice is directly converted into water vapor through sublimation, bypassing the liquid phase. This removes most of the water content.

Process:

① The pressure inside the freeze dryer is reduced to create a vacuum.

② Heat is gradually applied to provide the energy needed for sublimation.

③ Vaporized water is captured by a condenser, which prevents rehydration of the product.

Key control: Both temperature and pressure must be tightly controlled to optimize sublimation.

3. Secondary Drying Stage (Desorption)

Purpose: The remaining bound water is removed to achieve the desired low moisture content.

Process: Temperature is further increased under low-pressure conditions to desorb residual moisture. This ensures long-term stability of the product.

Key control: Temperature should be carefully raised to avoid damaging sensitive components in the product.

Therefore, temperature and humidity control are critical in a freeze dryer because they directly impact both the drying efficiency and the quality of the product. If you’re wondering how to manage such demanding temperature and humidity control environments, the answer is coming up next.

The Importance of Humidity and Temperature Control in Freeze Dryer

Ensuring Drying Efficiency

* Precise temperature control optimizes freezing, sublimation, and desorption, speeding up the drying process.

* Humidity regulation prevents moisture from slowing the process or being reabsorbed by the product.

Maintaining Product Quality

* Proper temperature control prevents overheating or uneven freezing, preserving product integrity.

*Controlling humidity ensures stability and avoids defects caused by excess moisture.

Enhancing Stability and Shelf Life

* Accurate control ensures the product is dry enough to resist microbial growth. This helps extend shelf life and improve storage stability.

Avoiding Inefficiencies

*Effective management ensures smooth and reliable processing. Inadequate control of temperature or humidity can result in extended drying times, increased energy consumption, or even process failures, impacting overall productivity.

*Proper management of both temperature and humidity not only improves drying efficiency but also ensures consistent product quality and stability, we can not deny the effect of humidity and temperature transmitters.

Role of Temperature and Humidity Transmitters in the Three Phases of Freeze Drying

Temperature and humidity transmitters play a critical role in ensuring optimal conditions throughout the freeze drying process. They provide real-time monitoring and control, improving drying efficiency and preserving product quality at every stage.

1. Application in Freezing Stage

The freezing stage requires precise temperature control to ensure uniform freezing of the product, preventing the formation of large ice crystals, which could damage the product’s structure.

Temperature transmitters provide real-time data on the chamber temperature, allowing operators to control the freezing rate. This helps avoid temperature fluctuations and ensures the product freezes evenly, preserving its integrity and optimizing the later drying stages.

Humidity transmitters help monitor environmental moisture levels, preventing unwanted moisture buildup during freezing.

2.Application in Primary Drying (Sublimation) Stage

Temperature transmitters help ensure that the heat applied during sublimation is sufficient but not excessive, maintaining the product’s structure and stability while efficiently removing moisture.

It also provide real-time data on moisture levels inside the chamber, allowing operators to adjust conditions to avoid any moisture re-entry into the product, which could interfere with the sublimation process. This real-time monitoring ensures that the product dries effectively and maintains its quality.

3. Application in secondary Drying (Desorption) Stage

In this phase, temperature transmitters regulate the heat during the secondary drying phase, ensuring that the product is gently heated to remove the remaining moisture without causing any degradation.

Transmitters monitor and control the humidity levels, preventing any moisture from re-entering the product. This precise control ensures that the product reaches its final stable, dry state with minimal risk of moisture-related issues.

Maintaining precise temperature and humidity control is vital for freeze-drying success. Inconsistent monitoring can lead to inefficiencies, reduced product quality, or even batch failures. That’s why having reliable tools is critical.

Висновок

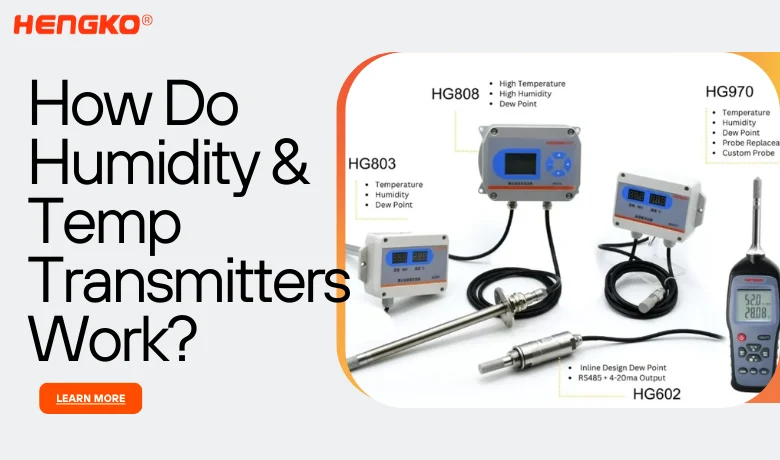

HENGKO’s advanced temperature and humidity transmitters are specifically designed to tackle these challenges. With real-time monitoring, precise data accuracy, and robust performance, they ensure your freeze dryer operates under optimal conditions at every stage. Whether you’re in pharmaceuticals, food, or R&D, our solution helps you achieve consistent, high-quality results every time.

Considering the demanding environment of freeze dryers, the HG808-D could be your ideal choice. Its anti-condensation function ensures accurate readings in high-humidity environments, while Modbus RTU facilitates seamless communication with PLC and DCS systems. With support for RS485 and analog outputs, it integrates easily into your freeze-drying system. The 15-bit analog resolution і optional 0.1 or 0.01 digital resolution provide precise monitoring of temperature, humidity, and dew point.

Having learned about these features, would you like to choose a transmitter to enhance your machine’s efficiency?

This guide – Як правильно вибрати датчик температури та вологості? can help you in selecting transmitter. Our engineers can also provide personalized advice based on your specific needs and usage scenarios. If you have any questions or require further assistance, please feel free to contact us at sales@hengkometer.com.