HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Pagrindinis " Portfelį " Dew Point Transmitter for Corrosive Environments HG808-G

Accurate Dew Point Monitoring for Corrosive and Chemically Aggressive Environments

The HG808-G is an industrial-grade transmitter for dew point, temperature, and humidity measurement in harsh chemical and solvent environments.

Made from 316L stainless steel with a nano-coated anti-corrosion finish, it ensures long-term accuracy and stability in the presence of acids, alkalis, and salt mist.

Key Features:

*Corrosion-Resistant Build: 316L stainless steel probe with protective coating

*Wide Measuring Range: Dew point −60 °C ~ +20 °C (−76 °F ~ +68 °F)

*High Accuracy: ±3 °C Td dew point, ±0.2 °C temperature

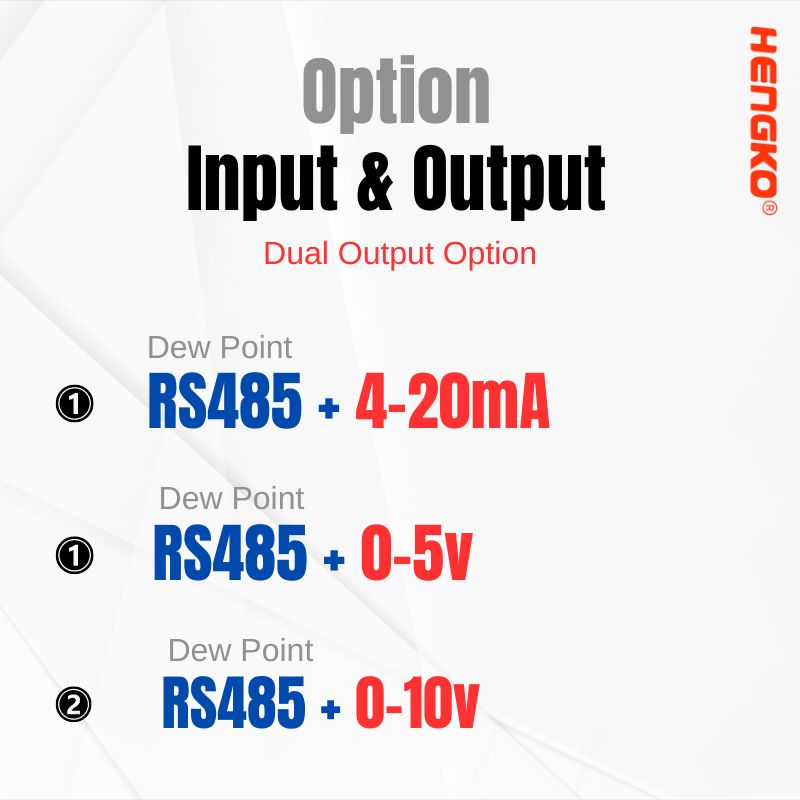

*Flexible Outputs: RS-485 (Modbus-RTU), 4–20 mA, 0–5 V / 0–10 V

*Industrial Protection: IP65 housing, 16 bar pressure resistance

*Fast Response < 1 s: Ideal for real-time process monitoring

*Easy Integration: Connects directly to PLC, DCS, or SCADA systems

Perfect for:

Chemical | Pharmaceutical | New-Energy | Solvent Recovery Processes

📩 Contact us to configure your corrosion-resistant dew point solution today.

Here’s a specification details for the HG808-G series Humidity Transmitter :

| Kategorija | Specifikacija |

|---|---|

| Measurement Parameters | Dew Point, Temperature, Humidity, PPM (for reference) |

| Rasos taško diapazonas | –60 °C ~ +20 °C |

| Dew Point Accuracy | ±3 °C Td (±5.4 °F) |

| Temperatūros diapazonas | –20 °C ~ +60 °C |

| Temperatūros tikslumas | ±0.2 °C (@ 23 °C) |

| Temperature Long-Term Stability | ≤ 0.1 °C / year |

| Humidity Long-Term Stability | ≤ 1 % RH / year |

| Digital Output | RS485 (Modbus-RTU); outputs temperature, humidity, dew point, PPM (humidity & PPM for reference only) |

| Analoginiai išėjimai | Temperature + Dew Point – select one: 4-20 mA / 0-5 V / 0-10 V |

| Atsparumas slėgiui | ≤ 16 bar |

| Baud dažnis | 1200, 2400, 4800, 9600, 19200, 115200 bps (selectable; default 9600 bps) |

| Įsigijimo dažnis | Fastest response 1 second; adjustable via PLC |

| Working Environment | –20 °C ~ +60 °C; 0 % ~ 95 % RH (non-condensing) |

| Maitinimo šaltinis | DC 12 V ~ 24 V, reverse-polarity protected |

| Energijos suvartojimas | < 0.5 W |

| Output Protocol | Standard Modbus-RTU; compatible with PLC, DCS, and SCADA systems |

| Construction | Compact aluminum housing with industrial grade ESD & anti-reverse protection |

| Installation & Customization | Custom probe design available according to application needs (structure, shape, length, material, mounting method) |

| Protection Rating | IP65 – dustproof and moisture-resistant |

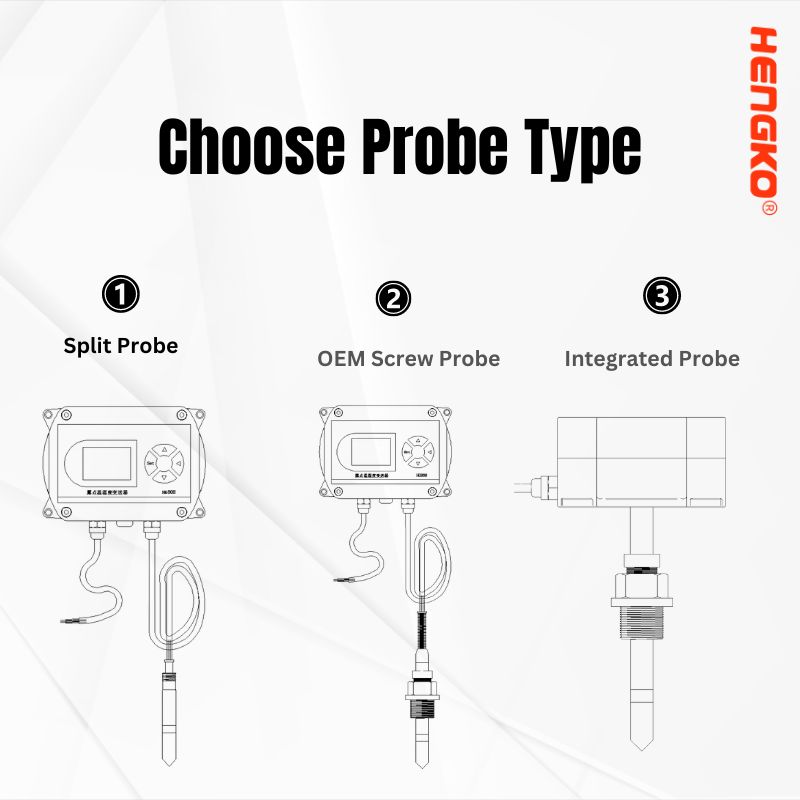

| Applicable Probe Options | Two probe types available: • Gas Sampling Unit • 316L Stainless Steel Sintered Protective Housing (A-Type, 0A# / 8A#) |

Siūlome 6 tipų zondus HG808 drėgmės siųstuvui, kurių kiekvienas gali būti tiek A, tiek B versijos, taigi iš viso yra 12 zondų įvairioms taikymo galimybėms.

0A#

8A#

M20 šešiakampio sriegio nerūdijančio plieno zondo jungtis

G1/2 Šešiakampio sriegio nerūdijančio plieno zondo jungtis

NTP1/2 Šešiakampio sriegio nerūdijančio plieno zondo jungtis

M27 šešiakampio sriegio nerūdijančio plieno zondo jungtis

M20 flanšinė nerūdijančio plieno zondo jungtis

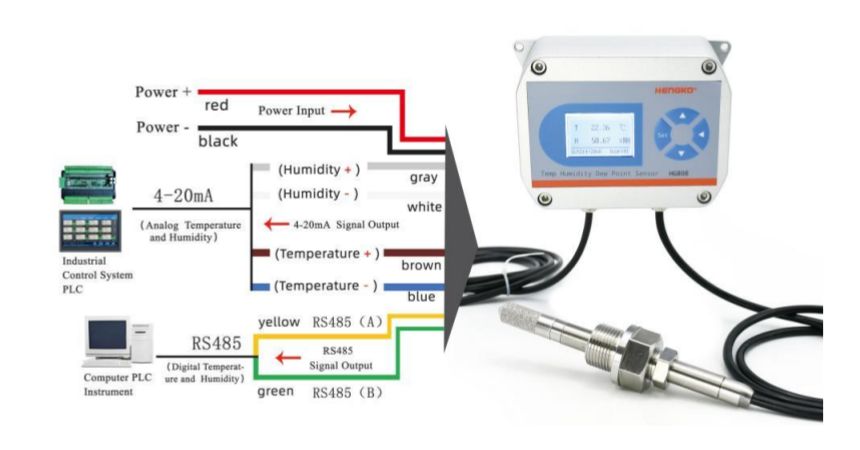

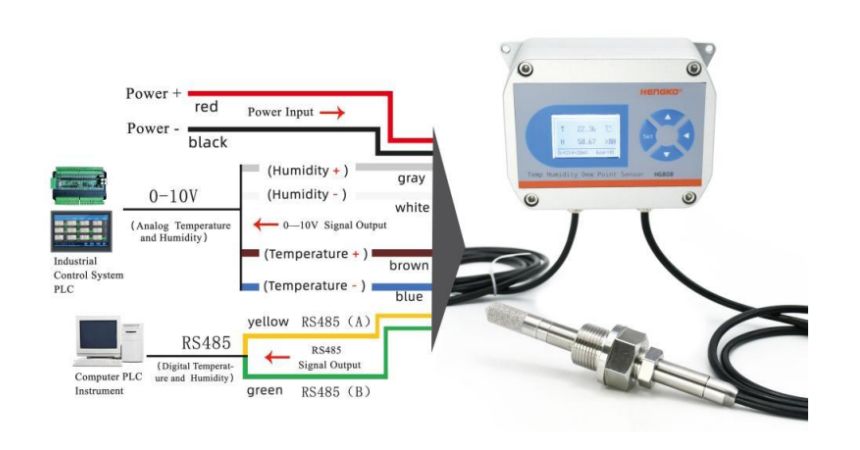

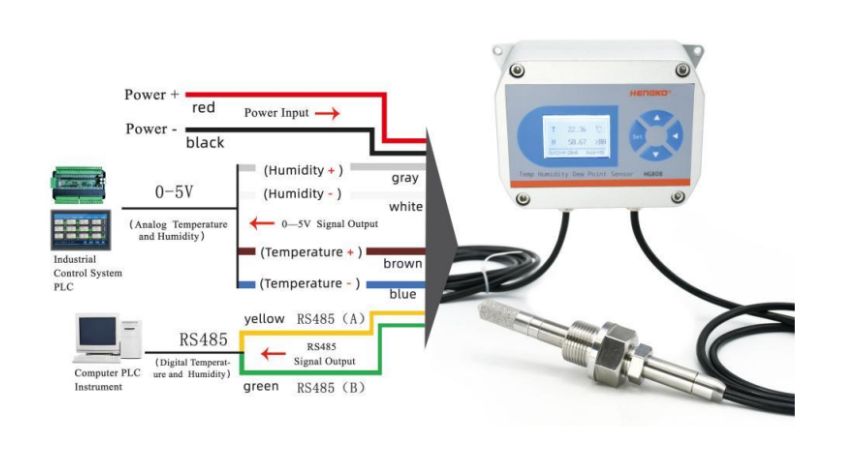

| Linijos spalva | Apibrėžimas | Specifikacija |

|---|---|---|

| Maitinimo laidas | ||

| Raudona | Teigiamas maitinimo šaltinis | 10 ~ 30 V NUOLATINĖS SROVĖS |

| Juoda | Neigiamas maitinimo šaltinis | GND |

| Analoginės išvesties linijos | ||

| Ruda | Teigiamas temperatūros signalas | 4-20 mA išvestis |

| Mėlyna | Neigiamas temperatūros signalas | Prijungiama prie juodos spalvos (GND) |

| Pilka | Teigiamas drėgmės signalas | 4-20 mA išvestis |

| Balta | Drėgmės signalas neigiamas | Prijungiama prie juodos spalvos (GND) |

| RS485 laidai | ||

| Geltona | RS485A | Vytos poros kabelis |

| Žalioji | RS485B | Vytos poros kabelis |

Papildomos pastabos:

Svarbu:

Precise dew point and humidity monitoring is critical to prevent moisture contamination of electrolyte solutions ir ensure uniform electrode coating quality.

Typical conditions: Dew point ≤ –40 °C, temperature 20 – 30 °C, humidity < 1 % RH.

Control requirement: Continuous online dew point monitoring in glove boxes and drying chambers for ultra-low humidity environments.

During chemical synthesis or solvent recovery, excessive moisture can affect reaction yield, purity, and safety. The HG808-G provides stable measurements even in acidic, solvent, or oil-vapor atmospheres.

Typical conditions: Dew point –40 ~ 0 °C, temperature 25 – 60 °C, humidity 5 – 40 % RH.

Control requirement: Corrosion-resistant dew point monitoring under HF, HCl, NH₃, or VOC exposure to prevent condensation and corrosion.

Humidity and temperature stability are essential to maintain API potency and drying uniformity. The HG808-G ensures accurate dew point and temperature control in cleanrooms and drying ovens.

Typical conditions: Dew point –30 ~ +10 °C, temperature 40 – 80 °C, humidity 2 – 20 % RH.

Control requirement: Real-time humidity feedback to optimize drying cycles and ensure GMP-compliant environmental monitoring.

FGD processes involve high-temperature, corrosive gases with varying moisture content. The HG808-G’s 316L stainless-steel probe withstands SO₂/SO₃ and acid mist for long-term reliability.

Typical conditions: Temperature 60 – 120 °C, humidity 10 – 80 % RH, dew point 0 ~ 50 °C.

Control requirement: Dew point monitoring for condensation control and corrosion prevention in gas treatment systems.

Stable dew point monitoring is required to prevent pipeline condensation, corrosion, and particulate accumulation in emission control systems.

Typical conditions: Temperature 30 – 90 °C, dew point –20 ~ 40 °C, humidity 5 – 70 % RH.

Control requirement: Continuous dew point trend tracking to maintain safe moisture levels before gas filtration or catalytic processing.

2. Pažymėkite "Visi kiti". Atsisiųsti failus

The HG808-G is engineered with an integrated corrosion-resistant structure, using 316L stainless steel and a sealed cast-aluminum housing (IP65). It resists acids, alkalis, electrolyte vapors, and chemical solvents, making it ideal for lithium battery, chemical, and pharmaceutical applications where standard sensors fail.

This transmitter has undergone strict testing for oil-gas mixtures, chemical corrosion, and dust impact. Its IP65-rated aluminum enclosure ir pressure-resistant 316L probe can withstand up to 16 barų, ensuring long-term stability and reliability even in challenging process environments.

The HG808-G offers flexible signal outputs for easy system integration:

Digital: RS485 (Modbus-RTU) for dew point, temperature, humidity, and PPM values.

Analog: Dual-channel outputs of 4-20 mA, 0-5 V, or 0-10 V (user selectable).

This design allows seamless connectivity with PLC, DCS, or SCADA systems for automated dew point and temperature control.

Yes. The transmitter includes data-recording functionality and supports connection to backend analysis software. Users can generate reports and trend charts with one click, enabling efficient monitoring, traceability, and process optimization.

The HG808-G can output dew point temperature, process temperature, relative humidity, and PPM values at the same time—providing a complete picture of gas dryness and system conditions.

By integrating advanced sensor technology and optimized circuitry, the HG808-G matches the performance of imported brands at a significantly lower cost. It delivers high precision, strong corrosion resistance, and excellent long-term stability, helping customers reduce maintenance and procurement costs.

Yes. HENGKO offers customized probe designs (structure, length, material, and mounting method) to meet specific process requirements—ensuring accurate and stable dew point measurement under any industrial condition.

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

The Role of Temperature and Humidity Monitoring Temperature and humidity transmitters are essential tools for modern dehumidification systems, providing real-time data on environmental conditions. By

Trumpai tariant, drėgmės ir temperatūros siųstuvai matuoja ir siunčia aplinkos duomenis į valdymo sistemas. Jie plačiai naudojami ŠVOK, farmacijos, maisto perdirbimo ir švarių patalpų srityse.

Kodėl suslėgto oro sistemoms labai svarbūs džiovintuvų rasos taško matuokliai? Galbūt visada kovojate su paslėpta suslėgto oro drėgme, kuri gali sukelti koroziją, užšalimą,

Kodėl vienoje biuro zonoje yra per daug drėgna ir kaip tai išspręsti drėgmės siųstuvu Nuolatinė drėgmė vienoje biuro zonoje gali sutrikdyti komfortą, padidinti pelėsių kiekį

Įvadas Suslėgtasis oras šiuolaikinėje pramonėje dažnai vadinamas "ketvirtąja komunaline paslauga", greta elektros, vandens ir dujų. Tačiau vienas iš labiausiai paplitusių

"WhatsApp" mums