Importance of Understanding Transducers and Transmitters

As We Know, Transducers and transmitters play a vital role in various applications by acting as the bridge between physical phenomena and the digital world. They are fundamental components in many industrial :

* Industrial automation:

Monitoring and controlling crucial process variables like pressure, temperature, flow, and level in industrial settings like chemical plants and power generation.

* Automotive industry:

Sensing vital parameters like engine pressure, air intake, and tire pressure for engine management and safety systems in vehicles.

* Medical field:

Measuring physiological data like blood pressure, heart rate, and oxygen saturation for patient monitoring and medical diagnosis.

* Environmental monitoring:

Tracking environmental changes such as temperature, humidity, and air quality for weather forecasting and pollution control.

After understanding how these devices function becomes essential for several reasons:

1. Troubleshooting and maintenance: Effective troubleshooting of equipment failures often requires knowledge of the underlying transducer or transmitter and its behavior.

2. Data interpretation: The data obtained from these devices needs proper interpretation in the context of the specific application and the unit’s operating principles.

3. Selecting appropriate equipment: Choosing the right transducer or transmitter for a particular application necessitates understanding the technical specifications and functionalities of these devices.

Understanding the Basics

1. What is a Transducer?

Definition:

A transducer is a device that converts energy from one form to another. This conversion typically involves transforming a physical quantity (like pressure, temperature, or sound) into an electrical signal.

Function:

Transducers act as the interface between the physical world and the world of electrical measurements and control systems. They allow us to measure and monitor various physical phenomena by converting them into a form that can be easily processed and analyzed by electronic devices.

2. Types of Transducers and Common Applications

There are numerous types of transducers categorized based on the type of physical quantity they convert and the corresponding output signal. Here are some common examples:

* Temperature transducers: These convert temperature variations into electrical signals using components like thermistors, resistance temperature detectors (RTDs), or thermocouples. Applications include temperature control in industrial processes, HVAC systems, and medical equipment.

* Pressure transducers: They convert pressure (force exerted per unit area) into electrical signals. Applications include monitoring pressure in hydraulic systems, air compressors, and weather stations.

* Position transducers: Examples include linear variable differential transformers (LVDTs) and rotary encoders, which convert linear or angular displacement into electrical signals. Applications encompass robotics, automation systems, and machine tool positioning.

* Sound transducers: Microphones convert sound waves into electrical signals, while loudspeakers perform the opposite function.

Tips : This list is not exhaustive, and there are many other specialized transducers used for measuring various physical properties like light, flow, vibration, and chemical composition.

3. What is a Transmitter?

* Definition: A transmitter is an electronic device that processes and transmits an electrical signal to a receiving device.

* Role in signal processing: While a transducer converts physical quantities into electrical signals, a transmitter often takes this one step further. It amplifies, modulates, and filters the electrical signal from the transducer to ensure its compatibility for transmission over long distances or through noisy environments.

4. Types of Transmitters and their Uses in Various Industries

1. Analog transmitters: These transmit a continuous electrical signal that directly corresponds to the variations in the measured physical quantity. They are commonly used in industrial process control applications where continuous monitoring is crucial.

2. Digital transmitters: These convert the analog signal from the transducer into a digital format (like a series of ones and zeros) for transmission. This allows for better noise immunity and facilitates easier data processing and storage. Applications include building automation systems and remote monitoring applications.

Industries using Transmitters:

* Process industries: Chemical plants, oil refineries, and power generation facilities heavily rely on transmitters for monitoring and controlling crucial process variables like pressure, temperature, and flow.

* Manufacturing: Transmitters are used in production lines for monitoring equipment performance, ensuring product quality, and controlling automated processes.

* Environmental monitoring: Remote monitoring of environmental parameters like air and water quality often utilizes transmitters for data transmission over long distances.

By understanding the functionalities of transducers and transmitters, we gain valuable insight into how physical phenomena are translated into electrical signals for measurement, monitoring, and control purposes in various applications.

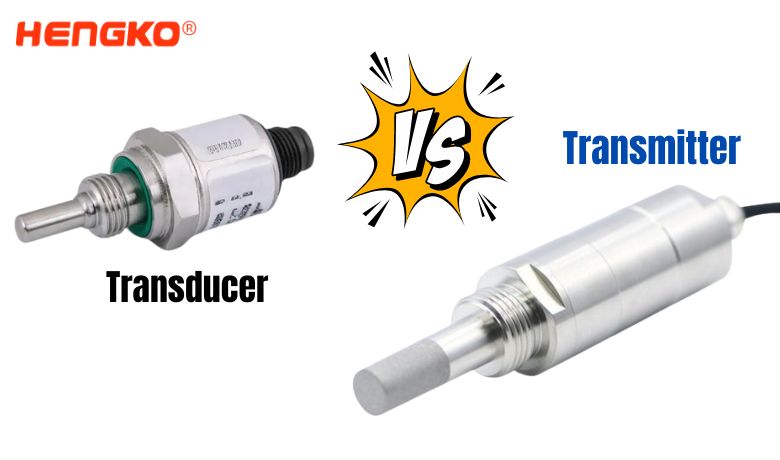

The Core Differences Between Transducers and Transmitters

While both transducers and transmitters play significant roles in signal processing, they differ in their specific functionalities and output characteristics.

Key Distinctions in Functionality:

* Transducer: Primarily focuses on conversion. It transforms a physical quantity into a basic electrical signal.

* Transmitter: Concerned with processing and transmission. It takes the electrical signal from a transducer, modifies it for better transmission, and transmits it to a receiving device.

Analogy: Consider a transducer as a sensor that detects a physical quantity and converts it into a raw voltage. The transmitter acts like an amplifier and signal conditioner, taking this raw voltage, enhancing it, and preparing it for sending over long distances.

Differences in Output Signals:

* Transducer: The output signal is typically a raw electrical signal that directly corresponds to the measured physical quantity. This signal might be weak and susceptible to noise.

* Transmitter: The output signal is a processed and conditioned electrical signal. It often gets amplified, filtered, or converted into a standard format (like 4-20mA current loop) suitable for long-distance transmission with minimal signal degradation.

Application-specific Contrasts:

* Transducers: Due to their simpler design, transducers are generally smaller and more affordable. They are suitable for short-distance applications where basic signal conversion is sufficient. Examples include temperature sensors in consumer electronics or pressure sensors in car tires.

* Transmitters: As they involve additional signal processing circuitry, transmitters are generally more complex and expensive than transducers. However, they offer several advantages:

1. Long-distance transmission: Transmitters can transmit signals over extended distances without significant signal loss.

2. Noise immunity: The processing and conditioning in the transmitter help to minimize the impact of electrical noise on the signal integrity.

3. Standardized output: Transmitters often convert the signal into a standard format (e.g., 4-20mA current loop) which simplifies integration with industrial control systems and data acquisition devices.

Here’s a table summarizing the key differences:

| Feature | Transducer | Transmitter |

|---|---|---|

| Functionality | Converts physical quantity to electrical signal | Processes and transmits electrical signal |

| Output Signal | Raw electrical signal | Processed and conditioned electrical signal |

| Applications | Short-distance measurements, cost-sensitive applications | Long-distance transmission, noisy environments, industrial control systems |

How Transducers Work

Transducers act as the bridge between the physical world and the electrical domain by transforming various physical quantities into measurable electrical signals. Here’s a deeper dive into their working principle:

Conversion Process:

1. Physical Quantity Detection:

The transducer element comes into direct contact with the physical quantity being measured (e.g., temperature, pressure, light). This element is designed to be sensitive to changes in the specific physical property.

2. Energy Conversion:

The physical quantity exerts a certain force or influence on the transducer element. This can involve phenomena like:

* Mechanical deformation: In pressure sensors, a diaphragm might bend due to applied pressure.

* Change or variation: Electrical resistance in a thermistor might change due to temperature variations.

* Piezoelectric effect: Certain materials (like quartz crystals) generate a voltage when subjected to mechanical stress.

3. Electrical Signal Generation:

The physical changes in the transducer element are translated into a corresponding electrical signal. This signal might be:

* Change in voltage: Voltage variations often occur in temperature sensors or pressure transducers using strain gauges.

* Current generation: Photovoltaic cells convert light energy into electrical current.

* Frequency shift: In some cases, the frequency of an oscillating signal might change based on the measured quantity.

Examples of Transducer Types:

1. Temperature Sensor:

* Type: Thermistor (resistance-based)

* Working Principle: Electrical resistance of the thermistor material changes with temperature. As temperature rises, resistance decreases.

* Application: Monitoring appliance temperatures, building automation systems.

2. Pressure Sensor:

* Type: Piezoresistive (strain gauge based)

* Working Principle: Applied pressure causes a diaphragm to deform, inducing strain on a bonded strain gauge. This strain changes the electrical resistance of the gauge, resulting in a voltage variation.

* Application: Monitoring hydraulic systems, air pressure gauges, weather stations.

3. Humidity Sensor:

* Type: Capacitive

* Working Principle: Changes in humidity alter the dielectric constant (permittivity) of the material between two capacitor plates. This variation in permittivity affects the capacitance, leading to a change in voltage across the capacitor.

* Application: Humidifiers, building ventilation systems, greenhouses.

Applications and Examples:

1. Medical Thermometers: Use thermistor-based transducers to convert body temperature into electrical signals displayed on the thermometer.

2. Tire Pressure Monitoring Systems (TPMS): Employ pressure transducers to monitor air pressure in car tires and alert drivers to potential underinflation.

3. Smoke Detectors: Utilize photoelectric transducers that detect changes in light scattering caused by smoke particles, triggering an alarm.

By understanding these principles, we gain insight into how diverse physical phenomena can be translated into the electrical domain using transducers, enabling us to measure, monitor, and control various processes in everyday life and industrial applications.

Exploring Transmitters

Building upon the foundation laid by transducers, transmitters play a crucial role in processing and transmitting electrical signals for various applications. This section delves into their inner workings and highlights their significance in control systems and communication.

Detailed Look into Processing and Sending Signals:

While transducers provide the initial conversion from physical quantities to electrical signals, these signals often require further processing before transmission. Transmitters perform the following functions:

1. Signal Amplification:

The weak electrical signal from the transducer might need amplification to overcome signal loss during transmission over long distances.

2. Signal Filtering:

The raw signal might contain noise or unwanted electrical disturbances. Transmitters employ filters to eliminate such noise and ensure the integrity of the transmitted data.

3. Signal Conditioning:

The signal might be converted into a standardized format suitable for long-distance transmission and compatibility with receiving devices. Common examples include:

* 4-20mA current loop: An industry-standard current loop where the measured quantity is directly proportional to the current flowing through the loop.

* Voltage scaling: Scaling the voltage signal to a specific range (e.g., 0-5V) for compatibility with data acquisition devices.

4. Modulation:

In some cases, the processed signal modulates a carrier signal (usually a high-frequency radio wave) for transmission over long distances or through wireless channels. This allows multiple signals to be transmitted simultaneously without interference.

5. Transmission: The transmitter utilizes an antenna to radiate the processed and, if necessary, modulated signal wirelessly or transmits it through cables for wired communication.

Role of Transmitters in Control Systems and Communication:

* Industrial Process Control: In factories and refineries, transmitters play a vital role in monitoring and controlling crucial process variables like pressure, temperature, and flow. They convert sensor signals into a standardized format for interfacing with controllers and ensuring stable process operation.

* Building Automation Systems: Transmitters monitor environmental conditions (temperature, humidity) and equipment performance in buildings, enabling efficient energy management and occupant comfort control.

* Remote Monitoring Applications: Transmitters facilitate the transmission of sensor data from remote locations (e.g., weather stations, environmental monitoring buoys) for centralized data acquisition and analysis.

Examples of Transmitter Applications in Industry:

* Oil and Gas Industry: Monitoring pressure, flow rate, and temperature of oil and gas pipelines using pressure and temperature transmitters.

* Chemical Manufacturing: Transmitters ensure precise control of reaction vessel pressure, temperature, and flow rates for safe and efficient chemical production.

* Power Generation: Monitoring critical parameters like boiler pressure, turbine speed, and generator output voltage using transmitters for reliable and efficient power generation.

By understanding the processing and transmission functionalities of transmitters, we gain appreciation for their significance in various industrial applications. They bridge the gap between sensor measurements and usable data, enabling effective monitoring, control, and automation in diverse sectors.

Selecting the Right Device for Your Needs

Choosing between a transducer and a transmitter requires careful consideration of the specific application requirements. Here are key factors to guide your decision:

1. Factors to Consider:

Measurement Distance:

* Transducer: Suitable for short-distance applications where the signal doesn’t need to travel far.

* Transmitter: Ideal for long-distance transmission as they amplify and condition the signal for minimal loss over extended distances.

Signal Strength:

* Transducer: Provides a raw electrical signal that might be weak and susceptible to noise.

* Transmitter: Amplifies the signal from the transducer, enhancing its strength and resilience to noise for better transmission quality.

Data Processing Needs:

* Transducer: Limited data processing capabilities.

* Transmitter: Offers features like signal filtering, scaling, and conversion to standard formats, simplifying data acquisition and integration with control systems.

Cost:

* Transducer: Generally less expensive due to simpler design.

* Transmitter: More complex and often incurs higher costs due to additional processing circuitry.

2. Compatibility:

Ensure the chosen device (transducer or transmitter) is compatible with existing equipment and data acquisition systems. Consider factors like:

* Output signal type: Match the output signal of the transducer/transmitter (e.g., voltage, current loop) with the input requirements of the receiving device.

* Communication protocols: Some transmitters utilize specific communication protocols (e.g., Modbus) for data transmission. Ensure compatibility with the data acquisition system.

3. Cost Considerations and Installation:

* Transducer: Lower upfront cost but might require additional signal conditioning circuitry for specific applications.

* Transmitter: Higher initial cost but offers a complete signal processing and transmission solution, potentially simplifying system design and installation.

* Installation: Transmitters might require additional wiring and configuration compared to transducers.

4. Summary Table:

| Factor | Transducer | Transmitter |

|---|---|---|

| Measurement Distance | Short | Long |

| Signal Strength | Weak, noise-prone | Strong, noise-resistant |

| Data Processing | Limited | Filtering, scaling, format conversion |

| Cost | Lower | Higher |

| Compatibility | Requires attention to output signal type | Requires attention to output signal type and communication protocols |

| Installation | Simpler | Might require additional wiring and configuration |

FAQ

What are some advantages of using transmitters over transducers?

Long-distance transmission: Transmitters amplify the signal, enabling it to travel longer distances without significant degradation.

Improved signal integrity: Filtering in transmitters reduces noise and ensures the accuracy of the transmitted data.

Standardized output: Transmitters often convert the signal into a standard format (e.g., 4-20mA current loop) for seamless integration with industrial control systems and data acquisition devices.

Are there any situations where a transducer might be preferable to a transmitter?

Cost-sensitive applications: For short-distance measurements where basic signal conversion is sufficient, transducers offer a simpler and more affordable solution.

Space constraints: Transducers are generally smaller and more compact than transmitters, making them suitable for applications with limited space.

How can I ensure compatibility between a transducer/transmitter and my existing system?

Output signal type: Verify that the output signal from the transducer/transmitter (e.g., voltage, current loop) matches the input requirements of the receiving device.

Communication protocols: If the transmitter utilizes specific communication protocols (e.g., Modbus) for data transmission, ensure compatibility with your data acquisition system.

Consult the device manuals or datasheets: These documents typically specify the technical details and compatibility information for the transducer/transmitter.

What are some additional factors to consider when choosing between a transducer and a transmitter?

Environmental conditions: In harsh environments with extreme temperatures, vibrations, or moisture exposure, a transmitter’s sealed enclosure might offer better protection for the internal circuitry compared to a transducer.

Required level of data processing: If your application requires advanced signal processing features like filtering, scaling, or conversion to a specific format, a transmitter would be the preferred choice.

Where can I find more information about specific transducers and transmitters?

Manufacturer websites: Most manufacturers provide detailed information about their products, including datasheets, specifications, and application notes.

Online resources: Several websites and forums offer technical information and discussions related to transducers and transmitters.