Dew Point Sensor for Compressed Air

Optimize Your Air Systems with Advanced Dew Point Monitoring

Casa " Dew Point Sensor for Compressed Air

Dew Point Sensor for Compressed Air Various Solution Supplier

Diverse Dew Point Solutions for Comprehensive Air System Management

HENGKO stands at the forefront of innovation as a leading supplier of dew point sensors for compressed air systems.

We offer a diverse range of solutions tailored to meet the international ISO 8573-1 standard for compressed air quality, compressed air needs to be dried and filtered to remove excess moisture and particulates.. Our dew point sensors ensure optimal performance and reliability in monitoring and managing air moisture levels, enhancing the efficiency and safety of compressed air operations across various industries.

Trust HENGKO to deliver superior, customized sensor solutions that drive your success.

Online Industrial Dew-Point Measurement - HG602

Caratteristiche principali

The HG602 is engineered for precision and reliability, providing essential dew point measurements for efficient compressed air system management.

- Campo di misura: -50°C to +20°C, perfect for diverse operating conditions.

- Pressure Capability: Handles pressures from -0.1 to 5.0 MPa with an optional high-pressure configuration up to 35 MPa (350 bar).

- Output and Communication: Offers both 4-20mA and HENGKO digital outputs to seamlessly integrate with existing control systems.

- Alimentazione: Efficient operation with 12-30Vdc at 60mA.

- Installation Flexibility: Compact design with G1/2″ male thread and IP65 rating for easy and secure installation.

- Enhanced Sensor Technology: Features a newly developed sensor for improved signal stability and long-term reliability down to -50°C.

- Versatile Fitting Options: Compatible with various measuring chambers for flexible integration into any piping scheme using push-fit or fast connectors.

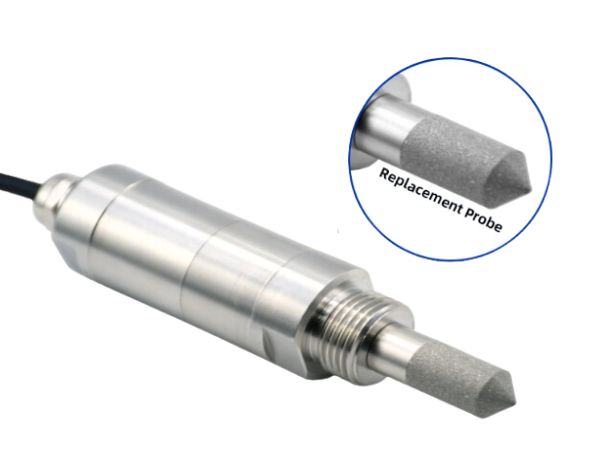

Handheld Industrial Dew Point Meter

- HG970 Series

Caratteristiche principali

The HG970 is engineered for exceptional performance in industrial environments, featuring a durable, replaceable metal probe design that ensures a long service life and easy installation.

This handheld meter is designed to deliver data quickly and accurately, with a fast response time significantly enhanced by a sensor purge function for rapid and precise moisture detection.

Reliable Measurements in Demanding Conditions:

The robust sensor of the HG970 withstands condensation and fully recovers from exposure to moisture, providing dependable readings even under challenging conditions.

Intuitive User Interface for Enhanced Usability:

The HG970 comes equipped with an easy-to-use graphical LCD display that offers clear visualization of data. Its intuitive interface coupled with extensive data-logging capabilities makes it an ideal tool for comprehensive moisture analysis on the go.

HG970meter is perfect for professionals needing quick, accurate dew point measurements and reliable performance in various industrial settings.

Why Need Dew-Point Measurements in Compressed Air ?

Dew-point measurements used in compressed air systems are crucial for several reasons, particularly in industrial settings where air quality directly impacts the operation and efficiency of pneumatic equipment and processes. As follow reasons are essential we list, please check :

Preventing Moisture Damage: Compressed air often contains moisture, which can condense into water droplets if the temperature of the air falls below the dew point. This condensation can lead to corrosion and damage in piping, equipment, and instrumentation. By measuring the dew point, you can ensure that the moisture content in the compressed air is at a safe level to prevent such damage.

Ensuring Product Quality: In many manufacturing processes, such as in pharmaceuticals, electronics, and food production, moisture can compromise the quality of the product. For example, excessive moisture can affect the coating processes, create defects in painting or lead to contamination. Dew-point measurements help maintain the required air quality standards to ensure product integrity.

Efficienza energetica: Running a dryer to reduce moisture in compressed air consumes energy. By accurately measuring and controlling the dew point, industries can optimize the operation of air dryers, ensuring they are used only when necessary, thereby saving energy and reducing operational costs.

Conformità agli standard: Various industries are governed by standards that dictate specific air quality levels, including moisture content. Dew-point measurements are a direct method to verify compliance with these standards, such as ISO 8573-1, which defines air quality levels, including moisture.

Sicurezza: In processes where compressed air comes into contact with highly reactive materials or is used in environments where there is a risk of explosion, controlling moisture is critical. Moisture in compressed air can significantly increase the risk of fire and explosion in such settings.

Operational Reliability: Proper dew-point measurement and control can increase the reliability of pneumatic tools and equipment powered by compressed air. Moisture can lead to pneumatic system malfunctions, frequent maintenance requirements, and shortened equipment lifespans.

Anyway, monitoring the dew point in compressed air systems is vital for maintaining equipment reliability, ensuring product quality, improving energy efficiency, achieving compliance with industry standards, and ensuring safety in manufacturing environments.

How to Choose Dew Point Sensor for Compressed Air

Choosing the right dew point sensor for a compressed air system is essential to ensure accurate monitoring and control of moisture, which can greatly impact system efficiency and product quality.

Here are some key considerations when selecting a dew point sensor:

- Campo di misura: Ensure the sensor covers the temperature extremes your system may face.

- Precisione: Opt for high accuracy and repeatability to maintain precise moisture control.

- Tempo di risposta: Choose a sensor with a quick response to rapidly changing conditions.

- Operating Pressure: Select a sensor rated for the system’s pressure to ensure durability and accurate readings.

- Resistance to Contaminants: Pick a sensor resistant to oils, chemicals, or particulates prevalent in your environment.

- Ease of Installation and Maintenance: Favor sensors that are straightforward to install and maintain.

- Output and Connectivity: Ensure compatibility with your existing monitoring systems, considering options like 4-20 mA, 0-10 V, or digital outputs.

- Condizioni ambientali: Verify that the sensor can withstand the specific environmental conditions it will face.

- Cost and Warranty: Balance the sensor’s cost with your budget and prioritize a good warranty for added security.

By carefully considering these factors, you can choose a dew point sensor that meets the specific needs of your compressed air system, ensuring efficient operation and protection against moisture-related issues.

Prodotti correlati

TROVA IL TRASMETTITORE DI TEMPERATURA E UMIDITÀ GIUSTO

Raccontateci oggi il vostro progetto

Raccontaci i dettagli del tuo progetto Monitor,

Vi forniremo la soluzione migliore a prezzi competitivi entro 3 giorni.

Vi forniremo la soluzione migliore a prezzi competitivi entro 3 giorni.

FAQ

What is a dew point sensor for compressed air, and why is it important?

- A dew point sensor is a device that measures the dew point of compressed air. The dew point is the temperature at which water vapor in the air condenses into liquid water. In compressed air systems, moisture can cause a number of problems, including:

- Corrosion of pipes and equipment

- Reduced efficiency of pneumatic tools and machinery

- Growth of mold and bacteria

- Contamination of products

By measuring the dew point of compressed air, you can ensure that the air is dry enough to prevent these problems. This can help to save money on maintenance costs, improve product quality, and extend the life of your compressed air system.

What are the different types of dew point sensors for compressed air?

There are two main types of dew point sensors for compressed air:

- Chilled mirror dew point sensors: These sensors work by cooling a mirror until water vapor condenses on its surface. The temperature at which condensation occurs is the dew point. Chilled mirror dew point sensors are very accurate, but they can be expensive and require regular maintenance.

- Electrical capacitance dew point sensors: These sensors measure the change in electrical capacitance of a material as it absorbs moisture. Electrical capacitance dew point sensors are less expensive than chilled mirror sensors and are generally easier to maintain. However, they may not be as accurate as chilled mirror sensors, especially at very low dew points.

What factors should I consider when choosing a dew point sensor for compressed air?

When choosing a dew point sensor for compressed air, you should consider the following factors:

- The required accuracy: How important is it to have a very precise measurement of the dew point?

- The dew point range: What is the expected range of dew points in your compressed air system?

- The pressure and temperature of the compressed air: Some dew point sensors are not suitable for use with high-pressure or high-temperature compressed air.

- The ease of use and maintenance: How easy is it to install, calibrate, and maintain the sensor?

- The cost: How much are you willing to spend on a dew point sensor?

How often should I calibrate my dew point sensor?

The frequency of calibration for a dew point sensor will depend on the specific sensor and the application. However, it is generally recommended to calibrate dew point sensors at least once a year. Some sensors may require calibration more frequently, depending on the use and environment.

Where should I install a dew point sensor in my compressed air system?

The ideal location for a dew point sensor will depend on your specific compressed air system. However, some general guidelines include:

- Installing the sensor after the air dryer to monitor the performance of the dryer.

- Installing the sensor at a point where the compressed air is used in a critical application.

- Avoiding locations where the sensor may be exposed to extreme temperatures or contaminants.

Diffondere il mondo

HENGKO è leader mondiale nelle soluzioni di sensori industriali, con una reputazione di design unico e prestazioni eccellenti. I nostri trasmettitori e sensori di temperatura e umidità sono utilizzati in un'ampia gamma di settori, tra cui quello alimentare e delle bevande, farmaceutico, manifatturiero e del monitoraggio ambientale.

0

+

Anni di esperienza

0

Vendite in tutto il mondo

0

K

Progetti industriali

Altri progetti popolari

Cantine

Perfezionare la conservazione: Gestire temperatura e umidità per l'invecchiamento del vino

Magazzini agricoli

Ottimizzazione dello stoccaggio delle colture: Stabilizzazione delle condizioni post-raccolta