HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Startseite " Portfolio " Hochtemperatur-Taupunktmessumformer mit kurzer Schraubsonde Serie HG808-D

Measure Dew Point Accurately up to +90 °C

— Even in Harsh Industrial Environments

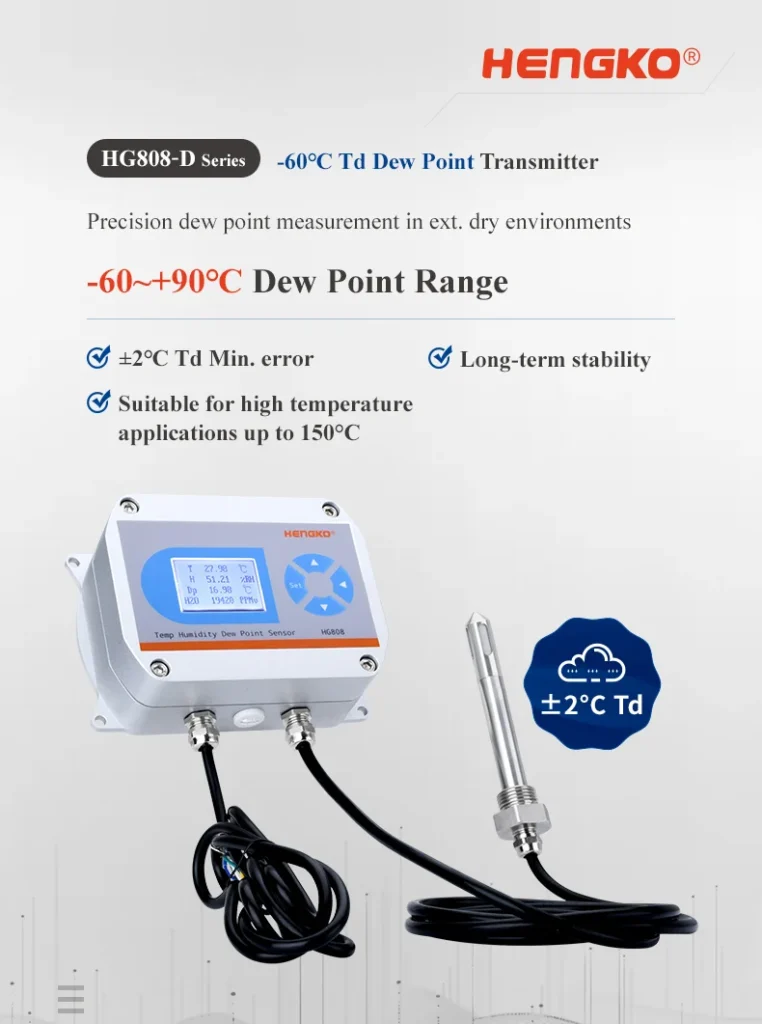

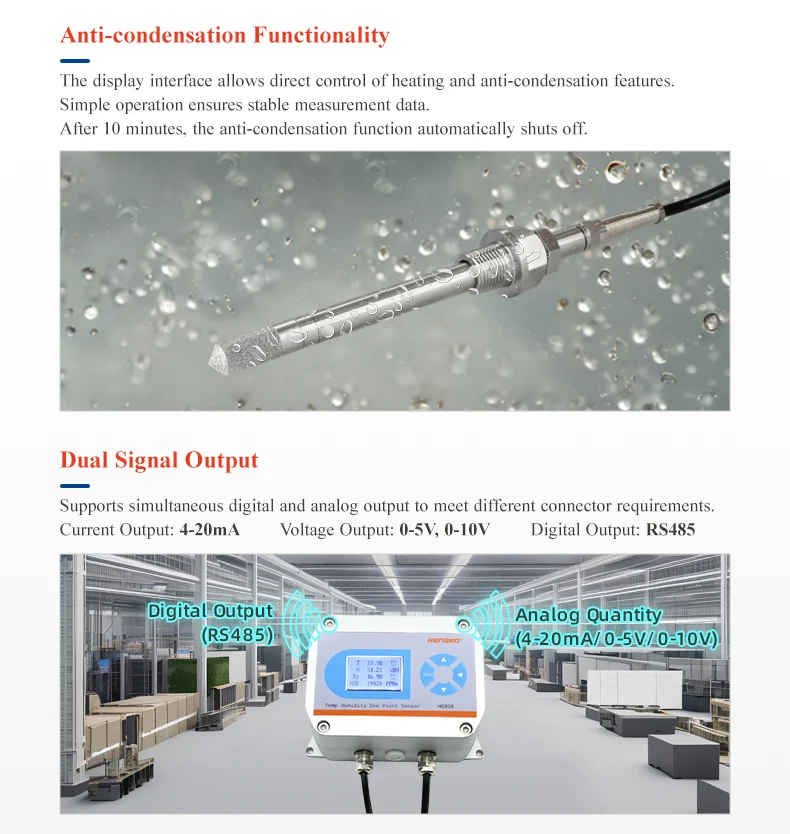

The HG808-D is a compact, high-performance transmitter for dew point, temperature, and humidity monitoring in high-temperature and demanding processes such as drying systems, ovens, and compressed air lines.

-Built with a durable high-temperature probe and IP65 housing, it ensures stable, accurate measurement even in hot, dusty, or humid conditions.

Key Features:

*Wide Measurement Range: Dew point −60 °C ~ +90 °C; Temperature −40 °C ~ +90 °C (−76 °F ~ +194 °F)

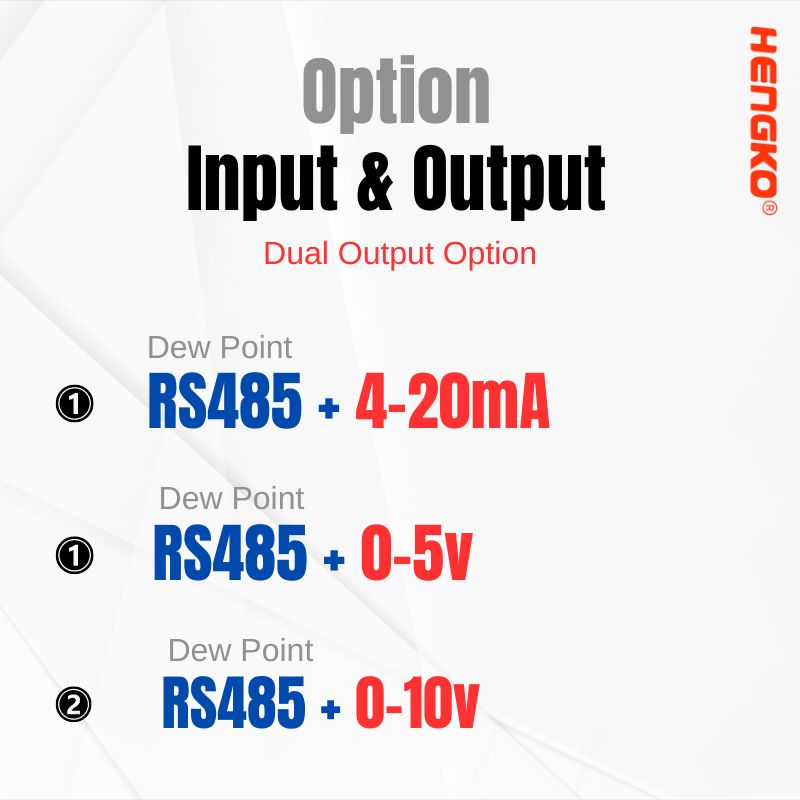

*Flexible Outputs: RS-485 (Modbus-RTU), 4-20 mA, 0-5 V / 0-10 V

*Integrated Display: Real-time view of dew point, temperature, and humidity

*Industrial Compatibility: Connects easily to PLC, DCS, or on-site display systems

Ideal for:

*Compressed air monitoring

*Industrial drying

*Environmental chambers

*Process control

📩 Contact us to customize your HG808-D solution today.

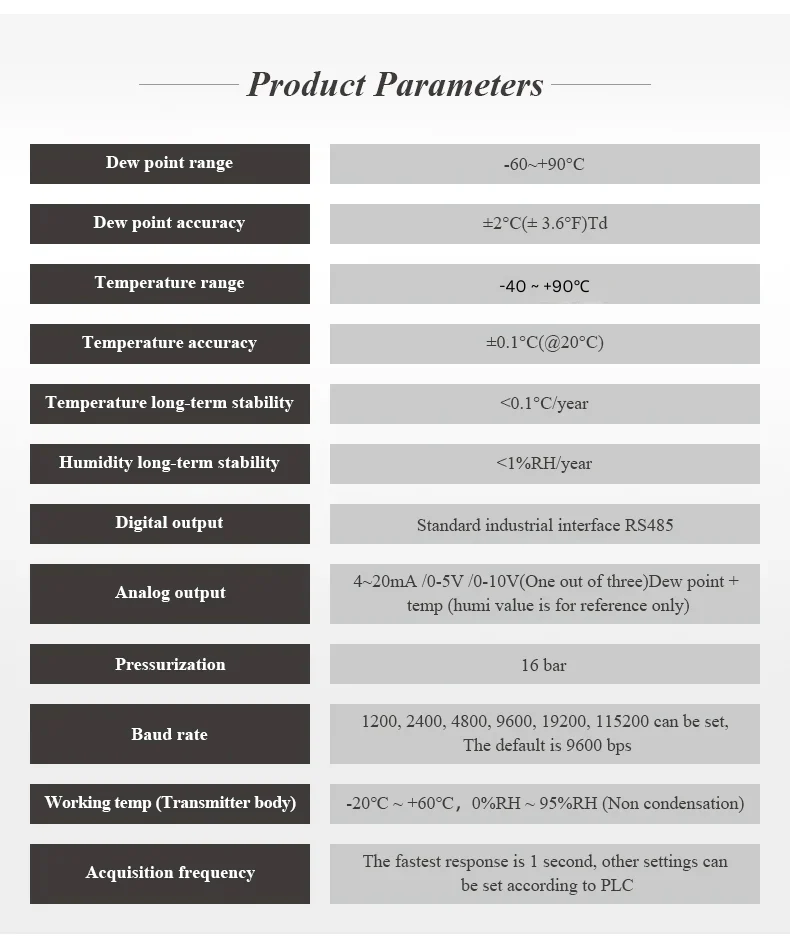

Here’s a specification details for the HG808-D series Dew Point Transmitter :

| Dew point range: | -60°C to +90°C |

|---|---|

| Temperaturbereich | -40 ~ +90°C |

| Luftfeuchtigkeitsbereich | 0 ~ 100% RH (Recommend < 95% RH) |

| Temperatur-Genauigkeit | ±0,1°C (BEI 20°C) |

| Dew Point Accuracy | ±2% RH (± 3.6 °F) Td |

| Stromversorgung | DC 10V ~ 28V |

| Stromverbrauch | < 0.5W |

| Analoge Ausgänge | Luftfeuchtigkeit + Temperatur: 4~20mA / 0-5V / 0-10V (einer von drei) |

| RS485 Digitaler Ausgang | Temperatur, Luftfeuchtigkeit, Taupunkt, PPM (gleichzeitig gelesen) |

| Auflösungsverhältnis | 0,01°C / 0,1°C (wahlweise) 0,01% RH / 0,1% RH (optional) |

| Baudrate | 1200, 2400, 4800, 9600, 19200, 115200 (Standard: 9600 bps) |

| Erfassungshäufigkeit | Schnellste Reaktion: 1 Sekunde; andere Einstellungen pro PLC |

| Byte Format | 8 Datenbits, 1 Stoppbit, keine Prüfung |

| Druckbeaufschlagung | 16 bar |

| Arbeitstemperatur | -20°C ~ +60°C, 0% RH ~ 95% RH (nicht kondensierend) |

| Sonde Typ | Split-Typ: Sonde 0 -Geteilter Typ :0A# / 0B# Probe 8 –Split type :8A# / 8B# |

Recommended Operating Conditions:

*Temperature: -40 … +90℃

*Dew Point: -60 … +90℃

*Application Environment:

Suitable for stable airflow, wind speed, and pressure conditions, and free from corrosive media, oil, or

Low-humidity or extremely dry environments with a wide dew point range.

chemical vapors.

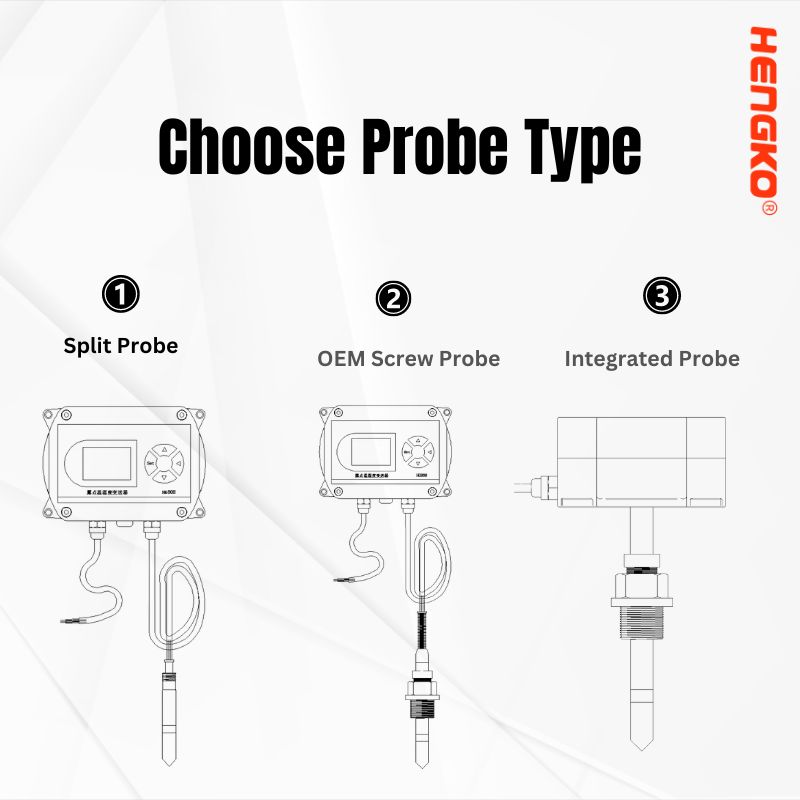

The HG808-D Series offers four probe types, each with A and B variants, allowing you to choose the ideal configuration for any humidity measurement environment.

0A#

8A#

0B#

8B#

M20 Hexagonal thread stainless steel Threaded Connection

G1/2 Hexagonal thread stainless steel Threaded Connection

NTP1/2 Hexagonal thread stainless steel probe Threaded Connection

M27 Hexagonal thread stainless steel Threaded Connection

M20 Flange stainless steel probe Threaded Connection

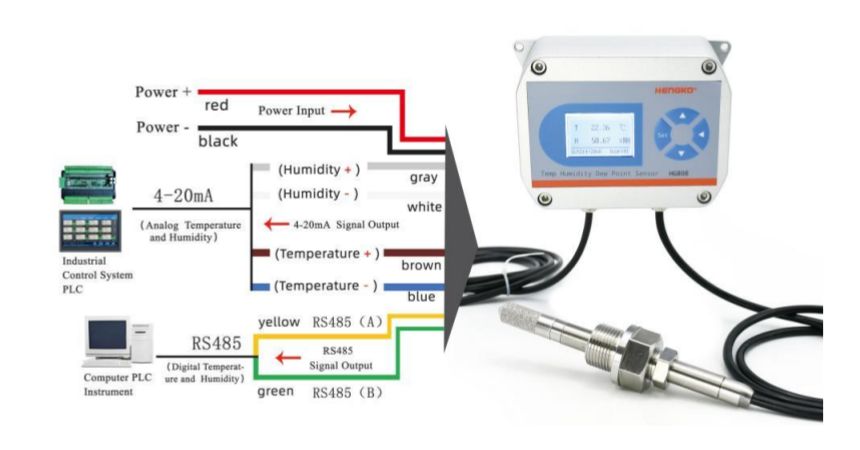

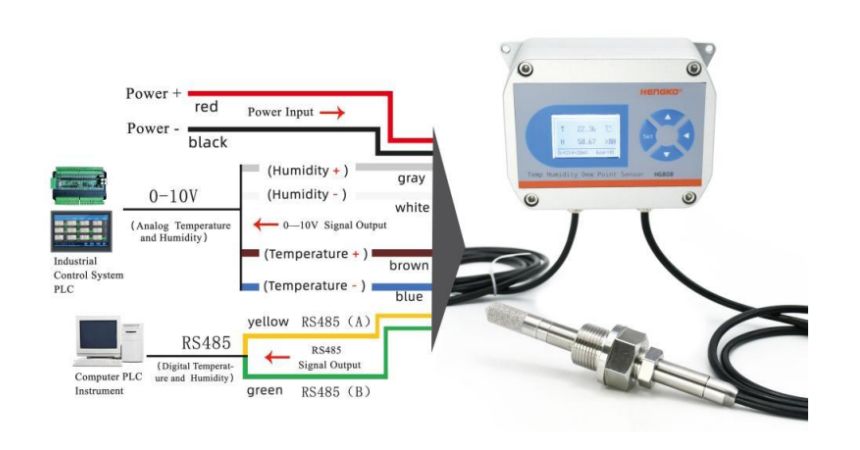

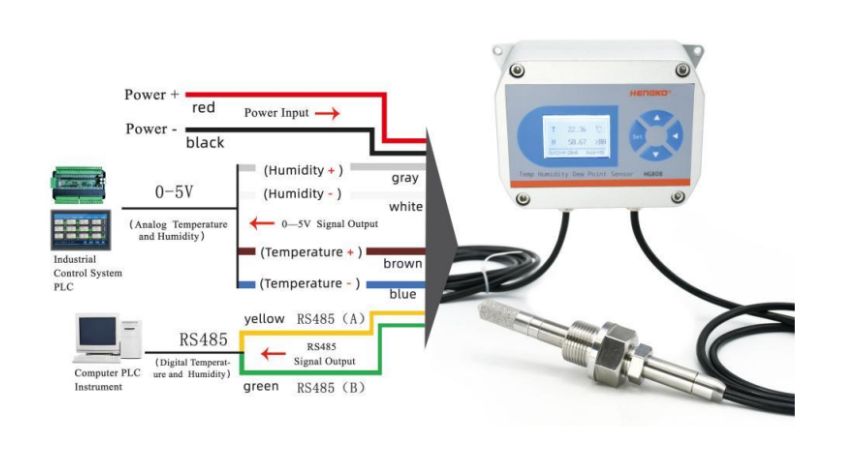

| Farbe der Linie | Definition | Spezifikation |

|---|---|---|

| Netzkabel | ||

| Rot | Spannungsversorgung positiv | 10 ~ 30V DC |

| Schwarz | Stromversorgung negativ | GND |

| Analoge Ausgangsleitungen | ||

| Braun | Temperatursignal positiv | 4-20mA Ausgang |

| Blau | Temperatursignal negativ | Wird mit Schwarz (GND) verbunden |

| Grau | Luftfeuchtigkeitssignal positiv | 4-20mA Ausgang |

| Weiß | Luftfeuchtigkeitssignal negativ | Wird mit Schwarz (GND) verbunden |

| RS485-Verdrahtung | ||

| Gelb | RS485A | Verdrilltes Kabel |

| Grün | RS485B | Verdrilltes Kabel |

Zusätzliche Hinweise:

Das ist wichtig:

Industrial processes often involve extreme temperatures and humidity levels. Regular transmitters can’t handle these harsh conditions. Here’s a breakdown of applications where high-temperature and humidity transmitters (operating over 200°C and down to -50°C) are crucial:

Here is a structured table for the applications of high-temperature and low-temperature transmitters in extreme environments:

| Anmeldung | Beschreibung |

|---|---|

| High-Temperature Applications (Over 200°C) | Industrial Ovens and Furnaces: Monitoring temperature and humidity is vital in curing processes like painting, drying ceramics, and heat treating metals. Precise control ensures product quality and prevents defects. |

| Power Generation: Humidity measurement in power plants helps prevent corrosion in turbines and other equipment exposed to high temperatures and steam. | |

| Chemische Verarbeitung: Accurate temperature and humidity data is essential for safe and efficient chemical reactions in reactors, dryers, and pipelines. Deviations can lead to hazardous situations or product contamination. | |

| Herstellung von Halbleitern: Creating microchips involves tightly controlled environments with high temperatures and low humidity. Transmitters ensure proper conditions for sensitive processes like photolithography and etching. | |

| Glass Manufacturing: Glass production requires precise temperature and humidity control during melting, blowing, and annealing. Transmitters help maintain consistent glass quality and prevent defects. | |

| Low-Temperature Applications (Down to -50°C) | Cold Storage Facilities: Monitoring temperature and humidity in freezers and cold warehouses helps maintain optimal conditions for food preservation and prevent spoilage. |

| Cryogenic Applications: Extremely low temperatures are used in research and industrial processes like superconductivity and liquefied natural gas (LNG) storage. Transmitters ensure safe handling and prevent equipment damage from ice formation. | |

| Climate Monitoring: These transmitters are valuable tools for weather stations in extreme cold environments like the Arctic or high mountain regions. They provide accurate data for climate research and weather forecasting. | |

| Aerospace Industry: Testing aircraft components for functionality in frigid conditions requires precise temperature and humidity control. Transmitters simulate real-world scenarios and ensure aircraft safety. | |

| Wind Turbine Icing: Detecting and measuring ice formation on wind turbine blades is crucial for safe operation. Transmitters help prevent blade damage and power generation loss in cold climates. |

Would you like any adjustments or additional details?

Dies sind nur einige Beispiele. Hochtemperatur- und Feuchtetransmitter spielen in verschiedenen Branchen eine wichtige Rolle, indem sie die Prozesskontrolle, Produktqualität und Sicherheit in extremen Umgebungen gewährleisten.

2. Alle anderen ankreuzen Dateien herunterladen

The HG808-D series is a robust dew point transmitter designed for measuring low dew point data in extremely low humidity conditions.

Die wichtigsten Merkmale sind:

Here is a table summarizing the key features:

| Merkmal | Beschreibung |

|---|---|

| Reliable Measurement | Ideal for air compression, refrigeration, membrane, and adsorption dryers. |

| Versatile Installation | Can be installed in industrial applications, including: – Pipeline drying with vacuum and dry gas purification – Thermal regeneration compressed gas – Adsorption drying |

| Comprehensive Gas Monitoring | Provides accurate online measurements of moisture in various gases, including flammable, inert, and corrosive types. Useful for detecting residual humidity behind plastic industry dryers. |

| Strict Humidity Control | Essential for low dew point measurement in: – Lithium battery production – Electronic component manufacturing – Semiconductor processes – Power engineering |

| Wide Application Scope | Commonly used for humidity detection in: – Air separation nitrogen production – Dry gases, compressed gases, natural gas, and liquefied gases – High-temperature sintering furnace protective gases – Electronics industry, insulation gases, and refrigerants – Rapid trace moisture analysis in food, pharmaceuticals, and machinery |

| Broader Use Cases | Suitable for: – Meteorological analysis – Power switches – Metal smelting – Petrochemical processes – Natural gas processing – Electronic manufacturing – Textiles – Aerospace where dew point measurement is critical |

For any measurement needs not met by the HG808-D series, please reach out to our customer service for alternative temperature and humidity measurement products.

Thank you for your interest!

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Effective moisture management is essential in facilities where materials, equipment, and processes depend on controlled environmental conditions. While dehumidifiers play a central role, their performance—and

Kurz gesagt, Feuchte- und Temperaturtransmitter messen und senden Umgebungsdaten an Kontrollsysteme. Sie werden häufig in den Bereichen HLK, Pharmazeutika, Lebensmittelverarbeitung und Reinräume eingesetzt.

Warum sind Trockner-Taupunktmessgeräte für Druckluftsysteme so wichtig? Vielleicht kämpfen Sie immer mit versteckter Feuchtigkeit in der Druckluft, die Korrosion und Einfrieren verursachen kann,

Warum eine Bürozone zu feucht ist und wie ein Feuchtigkeitsmessgerät Abhilfe schafft Anhaltende Feuchtigkeit in einer Bürozone kann den Komfort stören und zu Schimmel führen

Einleitung Druckluft wird in der modernen Industrie oft als "vierte Energiequelle" neben Strom, Wasser und Gas bezeichnet. Dennoch ist eine der häufigsten

WhatsApp uns