Why Measure Dew Point?

1.Dew point is a more accurate measure of humidity than relative humidity.

2.It directly tells us the temperature at which condensation occurs.

3.Understanding dew point is crucial in various applications:

*Weather forecasting: Predicting fog, frost, and precipitation.

*HVAC systems: Maintaining comfort levels and preventing mold growth.

*Industrial processes: Ensuring product quality and preventing corrosion.

*Agriculture: Optimizing crop growth and storage conditions.

What is a Dew Point Sensor?

A dew point sensor is a device used to measure and monitor the dew point temperature in various industrial and environmental applications. Here’s an overview of dew point sensors:

Definition and basic working principle:

Dew point sensors measure the temperature at which water vapor in the air begins to condense into liquid water. They typically work by detecting changes in electrical properties (such as capacitance or impedance) of a sensing element as it absorbs or releases water vapor from the surrounding air.

Types of dew point sensors:

1.Chilled mirror sensors:

*Use a cooled mirror surface and optical detection

*Highly accurate but sensitive to contaminants

*Expensive and require frequent maintenance

2.Capacitive polymer sensors:

*Use a hygroscopic polymer layer between electrodes

*Offer good accuracy, stability, and condensation resistance

*Suitable for a wide range of humidity levels

*Capacitive metal oxide sensors (e.g., aluminum oxide):

*Similar structure to polymer sensors but use a metal oxide layer

Excellent for very low dew points but less stable at higher ranges

Vulnerable to damage from high humidity and condensation

Common applications and examples:

*Compressed air systems: Monitoring air quality and preventing moisture-related issues

*Industrial drying processes: Ensuring proper drying of materials

*HVAC systems: Controlling humidity levels in buildings

*Medical and breathing air: Ensuring compliance with safety regulations

*Food and pharmaceutical industries: Quality control in production and packaging

*Plastics drying: Preventing material waste and maintaining product quality

*Mass transit: Ensuring safety and reliability in brake systems, doors, and AC units

Dew point sensors are crucial for early detection of condensation risks, preventing equipment damage, optimizing energy usage, and maintaining product quality in various industrial processes.

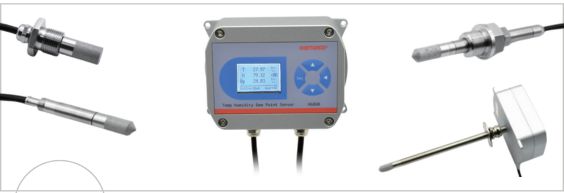

What is a Dew Point Transmitter?

Dew point transmitters are devices that measure and communicate dew point temperature in various industrial applications. Here’s an overview of dew point transmitters:

Definition and Basic Working Principle:

A dew point transmitter is an instrument that measures the dew point temperature and converts it into a standardized output signal, typically 4-20 mA. It works by detecting changes in the electrical properties of a sensing element as it absorbs or releases water vapor from the surrounding air, similar to dew point sensors.

How Transmitters Differ from Sensors:

While dew point sensors focus on detecting and measuring dew point, transmitters include additional components to process and communicate this information:

- Signal Processing: Transmitters contain electronics to convert the sensor’s raw data into a calibrated measurement.

- Output Signal: They provide a standardized output (e.g., 4-20 mA, Modbus RTU) for easy integration with control systems.

- Enclosure: Transmitters often have robust housings for protection in industrial environments.

- Display and Interface: Some models include digital displays and user interfaces for local readings and configuration.

Common Applications and Examples:

- Compressed Air Systems: Monitoring air quality and preventing moisture-related issues in industrial processes.

- Industrial Drying Processes: Ensuring proper drying of materials in manufacturing.

- Medical and Breathing Air: Ensuring compliance with safety regulations for patient care and firefighter equipment.

- Food and Pharmaceutical Industries: Quality control in production and packaging processes.

- Plastics Drying: Preventing material waste and maintaining product quality.

- Mass Transit: Ensuring safety and reliability in brake systems, doors, and AC units of trains and buses.

- HVAC Systems: Controlling humidity levels in buildings.

Examples of Dew Point Transmitters:

- Shaw Moisture Meters Model AcuDew: Compact, two-wire transmitters for industrial applications with ranges from -100 to +20°C dew point.

- E+E Elektronik Series EE354 and EE355: Designed for monitoring dew points in refrigeration dryers and OEM markets, respectively.

- Michell Easidew: Offers a wide measurement range from -100 to +20°C dew point with a 13-point calibration for high accuracy.

Dew point transmitters play a crucial role in various industries by providing accurate, real-time moisture measurements, enabling better process control and equipment protection.

Key Differences Between Dew Point Sensors and Transmitters

Comparison of Functionality and Integration

Dew Point Sensors:

- Functionality: Dew point sensors primarily focus on detecting and measuring the dew point temperature. They are the core components that sense changes in moisture levels in the air.

- Integration: Sensors are often integrated into larger systems or devices, such as transmitters, to provide raw data that needs further processing.

Dew Point Transmitters:

- Functionality: Dew point transmitters not only measure the dew point but also process the data and convert it into standardized output signals (e.g., 4-20 mA, Modbus RTU) for easy integration with control systems.

- Integration: Transmitters are designed for direct integration into industrial systems, offering robust housings, signal processing capabilities, and often include digital displays and interfaces for local readings and configuration.

Differences in Signal Output and Data Communication

Dew Point Sensors:

- Signal Output: Typically provide raw data that requires additional processing. They may output signals in forms that are not immediately usable by control systems without further conversion.

- Data Communication: Limited to providing basic measurement data without standardized communication protocols.

Dew Point Transmitters:

- Signal Output: Provide standardized output signals such as 4-20 mA or digital outputs like Modbus RTU, making them compatible with various industrial control systems.

- Data Communication: Equipped with advanced communication capabilities, enabling easy integration into monitoring and control systems. They can transmit processed and calibrated data directly to control units.

Accuracy, Range, and Reliability Comparison

Accuracy:

- Both sensors and transmitters are designed to provide high accuracy. However, transmitters often undergo calibration against reference standards (e.g., chilled mirror hygrometers) to ensure precise measurements across their range.

- Transmitters typically offer more consistent accuracy due to their integrated calibration and signal processing features.

Range:

- Sensors: The range can vary depending on the type of sensor used. For example, aluminum oxide sensors can measure very low dew points, while polymer sensors are better suited for moderate ranges.

- Transmitters: Often cover a broader range due to their ability to integrate multiple sensor technologies. For instance, some transmitters combine polymer and QCM sensors to measure a wide range of dew points from -100°C to +60°C.

Reliability:

- Sensors: Can be sensitive to environmental conditions and may require regular maintenance to ensure accuracy.

- Transmitters: Designed to be robust and durable, capable of operating in harsh industrial environments with minimal maintenance. They often include self-diagnostic features to alert users of any issues.

In summary, while dew point sensors are essential for detecting moisture levels, dew point transmitters enhance functionality by processing and communicating this data in a standardized and robust manner, making them more suitable for direct integration into industrial applications.

Factors to Consider When Choosing Between a Sensor and a Transmitter

When choosing between a sensor and a transmitter, there are several key factors to consider:

Output Signal Requirements:

- Sensors typically provide raw, unprocessed signals that may require additional processing.

- Transmitters provide standardized output signals (e.g. 4-20 mA, 0-10V) that can be directly used by control systems.

Integration Needs:

- Sensors are often integrated into larger systems or devices for basic measurement.

- Transmitters are designed for direct integration into industrial control systems, offering easier connectivity.

Signal Processing Capabilities:

- Sensors focus on detecting and measuring the parameter of interest.

- Transmitters include additional circuitry to process, linearize, and amplify the sensor signal.

Communication Capabilities:

- Sensors provide basic measurement data.

- Transmitters often have advanced communication protocols for interfacing with control systems.

Environmental Considerations:

- Transmitters typically have more robust housings for industrial environments.

- Sensor selection may depend more on the specific parameter being measured.

Accuracy and Stability:

- Transmitters often provide better overall accuracy and long-term stability due to integrated calibration and signal processing.

Range of Measurement:

- Transmitters may offer a wider measurement range by integrating multiple sensor technologies.

Cost Considerations:

- Sensors are generally less expensive than transmitters.

- Transmitters provide more functionality but at a higher cost.

Maintenance Requirements:

- Transmitters often require less frequent maintenance and calibration.

Application-Specific Needs:

- The choice ultimately depends on the specific requirements of the application, including accuracy needs, environmental conditions, and integration with existing systems.

When selecting between a sensor and transmitter, carefully evaluate these factors in the context of your specific application requirements to determine the most suitable option.

Installation and Maintenance Tips

Best Practices for Installing Dew Point Sensors and Transmitters

Choose a Suitable Location:

- Ensure the location is representative of the entire system being monitored. For compressed air systems, this could be near the compressor, after the dryer, or at the point of air consumption.

- Avoid placing the sensor near the bottom of pipe bends where lubricating oil or condensate might accumulate, as this can contaminate or damage the sensor.

Prepare the Mounting Surface:

- Clean the mounting surface thoroughly and ensure it is level to provide a stable base for the transmitter.

Install the Device:

- Securely mount the transmitter using appropriate hardware such as screws.

- For in-situ measurements, place the transmitter directly in the environment to be measured. For extractive measurements, install the sensor into a block within a sample handling system and flow the sample through this system.

Connect the Sampling Line:

- Connect the sample line to both the dew point transmitter and the point in the system where the dew point is to be monitored.

Power and Calibrate the Device:

- Connect the power supply and turn on the transmitter. Follow the manufacturer’s instructions for calibration to ensure accurate readings.

Monitor and Adjust:

- Regularly monitor dew point measurements to ensure system quality and make adjustments as necessary.

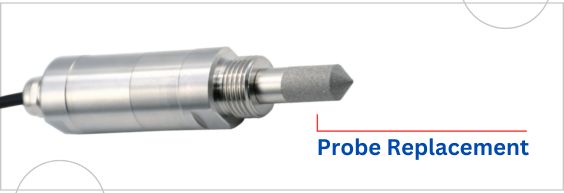

Maintenance Tips to Ensure Longevity and Accuracy

Regular Calibration:

- Calibrate the dew point sensor or transmitter at regular intervals as recommended by the manufacturer, typically every two years.

Keep Maintenance Records:

- Maintain detailed records of calibration and maintenance activities to track the device’s performance over time.

Avoid Contaminants:

- Ensure that the sensor is not exposed to contaminants such as oil, dust, or other particulates that can affect accuracy and longevity.

Protect from Harsh Conditions:

- Use transmitters with robust housings to protect against harsh environmental conditions, including extreme temperatures, pressures, and humidity levels.

Continuous Power Supply:

- Keep the device continuously powered to optimize measurement performance and availability. This helps in maintaining consistent operation and auto-calibration functions.

Check for Physical Damage:

- Regularly inspect the sensor and transmitter for any physical damage or wear and tear, and replace components as needed to ensure continued accuracy.

Follow Manufacturer’s Instructions:

- Adhere strictly to the manufacturer’s guidelines for installation, calibration, and maintenance to avoid voiding warranties and ensure optimal performance.

By following these best practices for installation and maintenance, you can ensure that your dew point sensors and transmitters provide accurate and reliable measurements over their operational lifespan.

Conclusion

In conclusion, understanding the differences between dew point sensors and dew point transmitters is crucial for effective humidity control and monitoring. Dew point sensors are ideal for direct and simple measurements, while dew point transmitters offer more advanced data communication and integration capabilities. When choosing between the two, consider your specific application needs, environmental factors, and budget. By selecting the right device, you can ensure accurate and reliable dew point measurements, enhancing your system’s performance and longevity.