HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

Item Number: HG808-F Series

Designed for Harsh Industrial and Corrosive Environments

The HG808-F series transmitter is engineered for long-term, stable temperature and humidity monitoring in corrosive environments such as chemical plants, coastal factories, fermentation chambers, and exhaust gas pipelines.

With a high-grade 316L stainless steel probe and flexible installation options, it ensures reliable data output under acid, alkali, salt, and high-humidity conditions.

Corrosion-Resistant Temperature and Humidity Transmitter

✅ High Corrosion Resistance

Built with 316L stainless steel probe housing to withstand acid, alkali, salt mist, and high humidity environments.

✅ Wide Measurement Range

Temperature: -40°C to +120°C

Humidity: 0–95%RH

Optional: Dew point, CO₂, PPM output available for multi-parameter applications.

✅ Flexible Installation

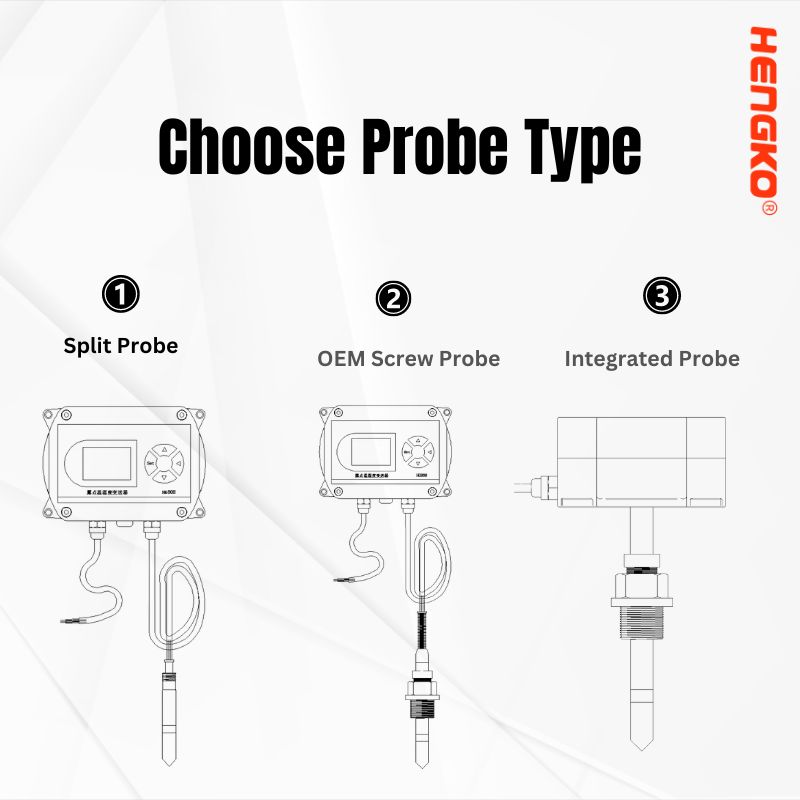

Available in multiple probe styles (0A, 3A, gas sampling unit), customized per site requirements.

✅ Industrial-Grade Durability

Designed for demanding conditions with up to 16 bar pressure resistance and long-term stability.

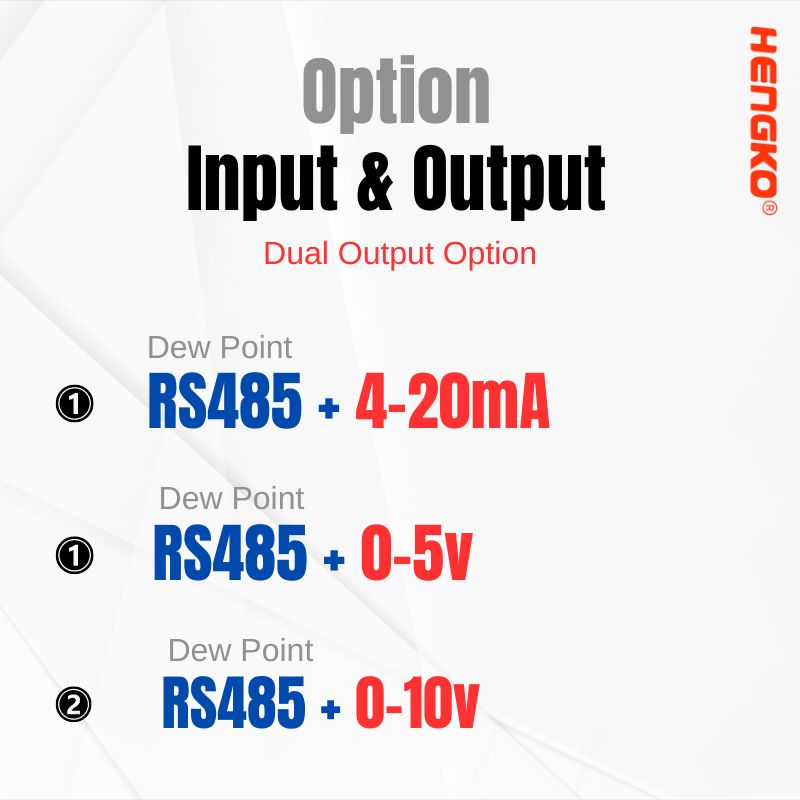

✅ Multiple Output Options

Supports 4–20mA / 0–5V / 0–10V analog output + RS485 Modbus-RTU for seamless integration.

✅ Smart Features

Real-time monitoring, multi-parameter support, optional display interface, and remote PLC adjustability.

✅ Ideal for Harsh Environments

Widely used in chemical factories, coastal industries, wastewater treatment, fermentation systems, and acid gas pipelines.

Here’s a specification details for the HG808-H series Humidity Transmitter :

| Category | Specification |

|---|---|

| Model | HG808-F Series |

| Temperature Measurement Range | -40°C to +120°C |

| Humidity Measurement Range | 0–95% RH |

| Temperature Accuracy | ±0.2°C (at 23°C) |

| Humidity Accuracy | ±2.0% RH (at 23°C, 10–90%RH) |

| Long-Term Stability | ≤1.0% RH/year |

| Sensor Output | Temperature, Humidity, Dew Point (optional), CO₂ (optional), PPM (optional) |

| Output Signal Options | Analog: 4–20mA / 0–5V / 0–10V (selectable) |

| Digital: RS485 (Modbus-RTU) | |

| Operating Pressure | ≤16 bar |

| Communication Baud Rates | 1200, 2400, 4800, 9600, 19200, 115200 bps |

| Material | 316L stainless steel (probe housing) |

| Probe Type | 0A: Duct/Wall Type Probe (for general use) 3A: Rod Type Probe (long tube, deeper insertion) Gas Sampling Probe: Threaded fitting for closed pipeline or gas sampling |

| Operating Environment | Acidic, alkaline, salty, high-humidity, and chemically corrosive environments |

| Power Supply | 12–24V DC standard |

| Display Option | Optional integrated digital display |

| Installation Method | Wall-mounted / Duct-mounted / Custom threaded or flanged installation |

| Configuration Features | Parameters adjustable via RS485 or PLC |

| Applications | Chemical plants, fermentation tanks, coastal factories, exhaust pipelines, gas monitoring systems |

We offer 6 types of probes for the HG808 Humidity Transmitter, with each type available in both A and B versions, providing a total of 12 probes for various application options.

0A#

1A#

3A#

5A#

6A#

8A#

0B#

1B#

3B#

5B#

6B#

8B#

M20 Hexagonal thread stainless steel probe connector

G1/2 Hexagonal thread stainless steel probe connector

NTP1/2 Hexagonal thread stainless steel probe connector

M27 Hexagonal thread stainless steel probe connector

M20 Flange stainless steel probe connector

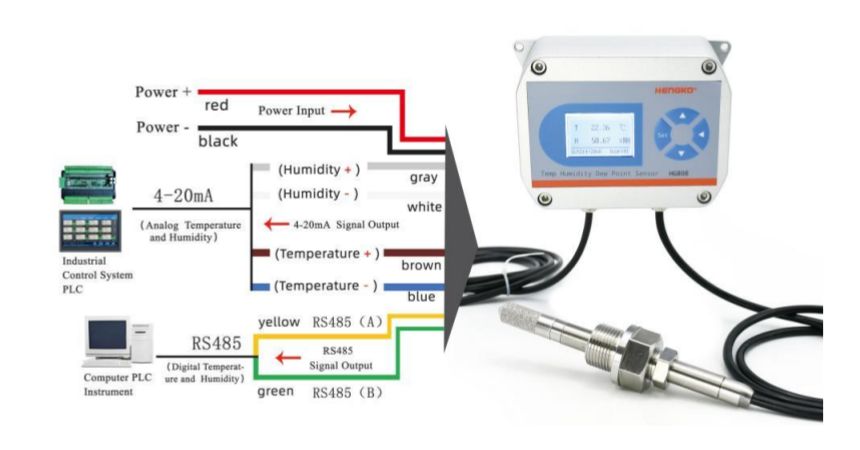

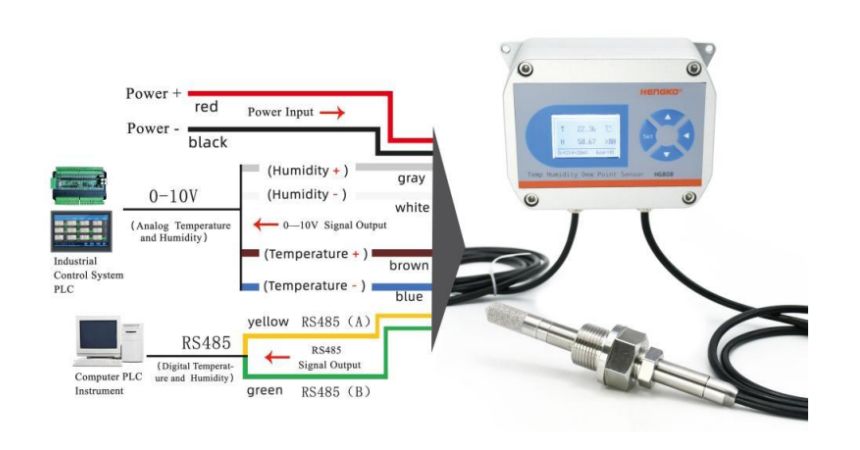

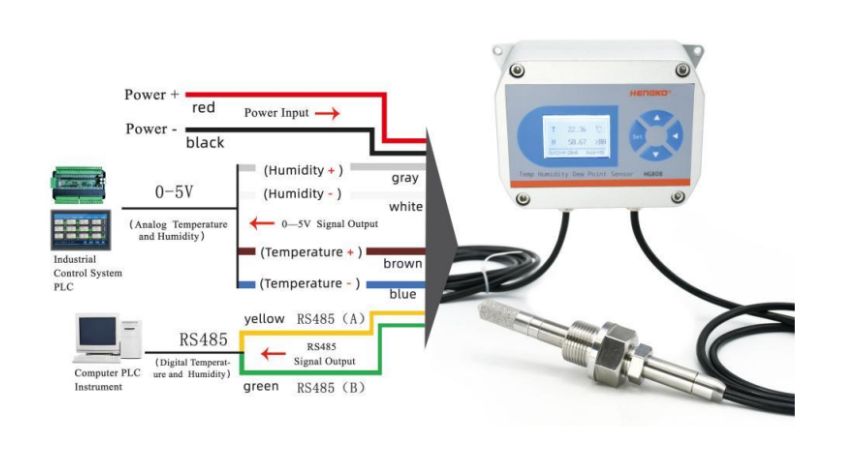

| Line Color | Definition | Specification |

|---|---|---|

| Power Cord | ||

| Red | Power supply positive | 10 ~ 30V DC |

| Black | Power supply negative | GND |

| Analog Output Lines | ||

| Brown | Temperature signal positive | 4-20mA output |

| Blue | Temperature signal negative | Connects to Black (GND) |

| Grey | Humidity signal positive | 4-20mA output |

| White | Humidity signal negative | Connects to Black (GND) |

| RS485 Wiring | ||

| Yellow | RS485A | Twisted pair cable |

| Green | RS485B | Twisted pair cable |

Additional Notes:

Important:

Industrial processes often involve extreme temperatures and humidity levels. Regular transmitters can’t handle these harsh conditions. Here’s a breakdown of applications where high-temperature and humidity transmitters (operating over 100°C and down to -40°C) are crucial:

These are just a few examples. High-temperature and humidity transmitters play a vital role in various industries by ensuring process control, product quality, and safety in extreme environments.

The HG808-F Series is a professional-grade temperature and humidity transmitter specially engineered for long-term operation in highly corrosive and harsh industrial environments. Designed with 316L stainless steel probe housing, the HG808-F offers exceptional resistance to acid, alkali, salt mist, high humidity, and chemically reactive gases, making it an ideal solution for chemical plants, coastal sites, fermentation tanks, and exhaust pipelines.

This transmitter supports multiple output formats, including 4–20mA, 0–5V/0–10V, and RS485 Modbus-RTU, ensuring seamless integration with existing control and automation systems. With a configurable probe design (0A, 3A, or gas sampling unit), the HG808-F offers installation flexibility to match diverse field requirements.

HG808-F is not just durable, but also intelligent — supporting optional multi-parameter outputs such as dew point, PPM, and CO₂, as well as real-time configuration through RS485 or PLC interfaces. Whether used in aggressive chemical production areas or coastal electronics facilities, the HG808-F ensures stable and accurate environmental monitoring, protecting your process and equipment.

High Corrosion Resistance:

316L stainless steel construction resists acid, alkali, salt, and high-humidity exposure.

Wide Measurement Range:

Temperature: -40°C to +120°C; Humidity: 0–95%RH; optional dew point, PPM, CO₂ outputs.

Multiple Probe Types Available:

Customizable 0A, 3A, and gas sampling probes for wall, duct, or sealed pipeline installation.

Flexible Output Options:

Analog (4–20mA / 0–5V / 0–10V) + RS485 Modbus-RTU for compatibility with industrial systems.

Industrial-Grade Durability:

Designed to withstand pressures up to 16 bar and long-term operation in extreme environments.

Smart Configuration:

Adjustable parameters via RS485/PLC; supports multi-channel monitoring and system feedback.

OEM Customization Supported:

Sensor configuration, housing material, and output signal can be tailored to your application.

Typical Applications Include:

Petrochemical plants, marine/coastal manufacturing sites, biopharmaceutical fermentation rooms, acid/alkali exhaust gas monitoring.

HG808-T High-Temperature Humidity Transmitter for Industrial Drying Ovens In many manufacturing processes, drying is more than just a step — it’s a decisive factor that

The Role of Temperature and Humidity Monitoring Temperature and humidity transmitters are essential tools for modern dehumidification systems, providing real-time data on environmental conditions. By

In short, Humidity and temperature transmitters measure and send environmental data to control systems. They are widely used in HVAC, pharmaceuticals, food processing, and cleanrooms

Why Are Dryer Dew Point Meters Critical for Compressed Air Systems? Maybe You always battle hidden moisture in compressed air that can cause corrosion, freezing,

Why One Office Zone is Too Humid & How a Humidity Transmitter Fixes It Persistent humidity in one office zone can disrupt comfort, increase mold

Introduction Compressed air is often referred to as the “fourth utility” in modern industry, alongside electricity, water, and gas. Yet, one of the most common

WhatsApp us