Optimize Nitrogen Systems with Temp&RH Sensor Solutions

In air separation nitrogen generation systems, high-purity gas output depends on more than just core components like compressors, dryers, and PSA towers. One often-overlooked factor

Item Number: HG808-H Series

Breakthrough Sensor Technology

— Reliable in 95–98% RH, Stable & Accurate Measurement

The HG808 is a next-generation industrial humidity transmitter engineered for ultra-high humidity environments.

With advanced sensor protection and durable probe construction, it ensures long-term operation in 95–98% RH without failure or drift. Ideal for food drying, pharmaceutical manufacturing, kilns, and harsh processing conditions, the HG808 delivers high-precision, stable measurements even in saturated, steamy environments.

✅-Exceptional Stability in High Moisture

Long-term operation in near-saturation humidity without degradation or drift.

✅-Precision Sensor Technology

High accuracy ±2% RH, ±0.2°C ensures reliable data for critical control systems.

✅-Robust Construction

Withstands harsh process environments, reducing downtime and maintenance.

✅-Safety & Compatibility

Built-in ESD protection, reverse polarity protection, and standard Modbus protocol ensure safe, seamless deployment.

HG808-H High Humidity Temperature Humidity Transmitter

✅ High-Humidity Durability (95–98% RH)

New-generation design resists damage from long-term exposure to moisture-saturated environments.

✅ Precision & Stability

Maintains accurate readings even under rapid temperature and humidity fluctuations.

✅ Wide Measurement Range

Temperature: -40°C to 190°C

Humidity: 0–98% RH

✅ Real-Time Dew Point Calculation

Built-in algorithm to monitor and manage condensation risks.

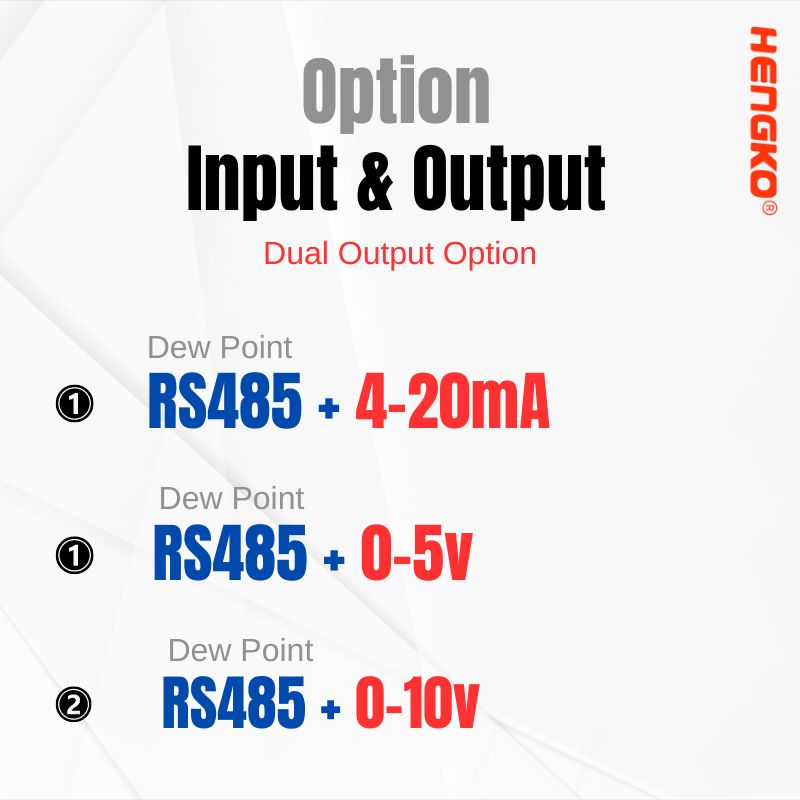

✅ Multi-Signal Output

Supports RS485 Modbus RTU, 4–20mA, and optional 0–5V / 0–10V for easy integration.

✅ Durable Industrial Probe

Waterproof, anti-corrosion sensor housing with sintered metal filter for dust and vapor resistance.

✅ Optional Local Display

On-screen T/RH/Dew Point readouts available for real-time monitoring.

✅ Industrial System Compatibility

Easily connects with:

*On-site digital meters

*PLCs (Programmable Logic Controllers)

*Frequency converters

*Industrial host control systems

Here’s a specification details for the HG808-H series Humidity Transmitter :

| Category | Specification |

|---|---|

| Temperature Range | -40 ~ +100°C (or -40°F to 212°F) |

| Humidity Range | 0 ~ 100% RH (Recommend < 98% RH) |

| Temperature Accuracy | ±0.1°C (@ 20°C) |

| Humidity Accuracy | ±2% RH (@ 20°C, 10 ~ 90% RH) |

| Power Supply | DC 10V ~ 28V |

| Power Consumption | < 0.5W |

| Analog Outputs | Humidity + Temperature: 4~20mA / 0-5V / 0-10V (one out of three) |

| RS485 Digital Output | Temperature, humidity, dew point, PPM (read simultaneously) |

| Resolution Ratio | 0.01°C / 0.1°C (optional) 0.01% RH / 0.1% RH (optional) |

| Baud Rate | 1200, 2400, 4800, 9600, 19200, 115200 (default: 9600 bps) |

| Acquisition Frequency | Fastest response: 1 second; other settings per PLC |

| Byte Format | 8 data bits, 1 stop bit, no check |

| Pressurization | 16 bar |

| Working Temperature | -20°C ~ +60°C, 0% RH ~ 95% RH (Non-condensation) |

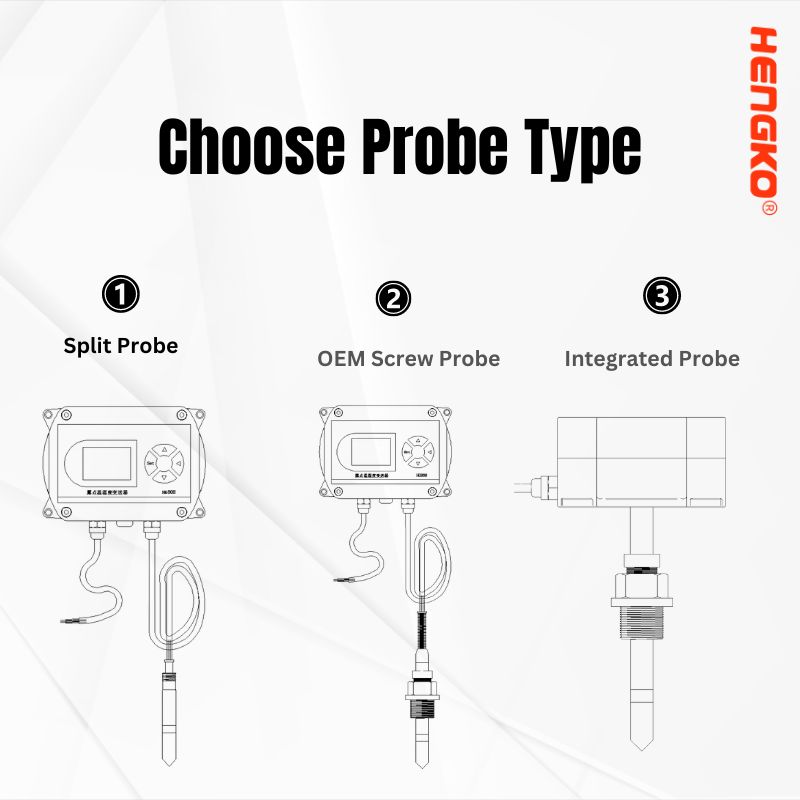

| Probe Type | Split type: Probe 5 – Pipeline :5A# / 5B# |

We offer 6 types of probes for the HG808 Humidity Transmitter, with each type available in both A and B versions, providing a total of 12 probes for various application options.

0A#

1A#

3A#

5A#

6A#

8A#

0B#

1B#

3B#

5B#

6B#

8B#

M20 Hexagonal thread stainless steel probe connector

G1/2 Hexagonal thread stainless steel probe connector

NTP1/2 Hexagonal thread stainless steel probe connector

M27 Hexagonal thread stainless steel probe connector

M20 Flange stainless steel probe connector

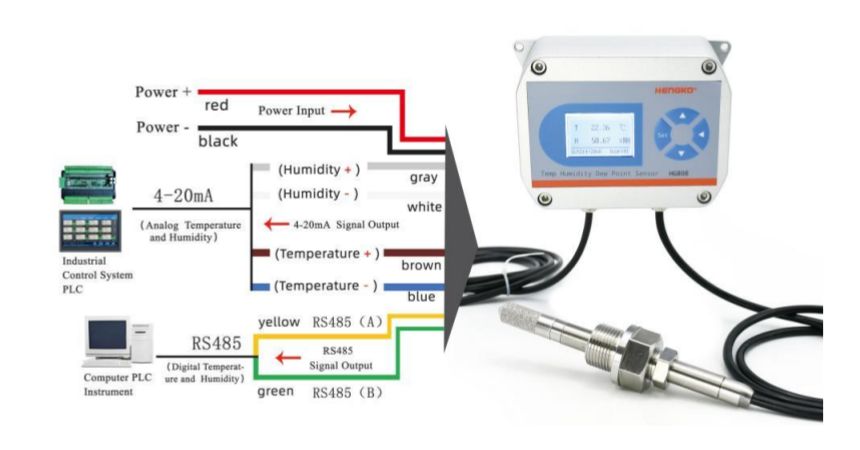

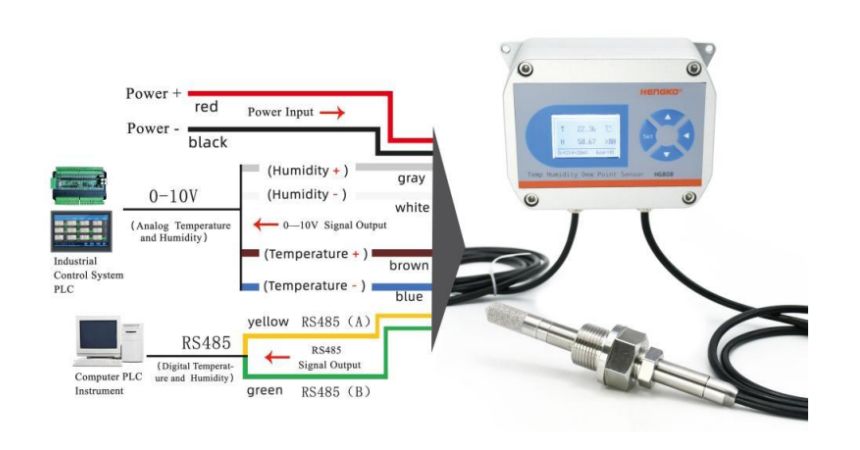

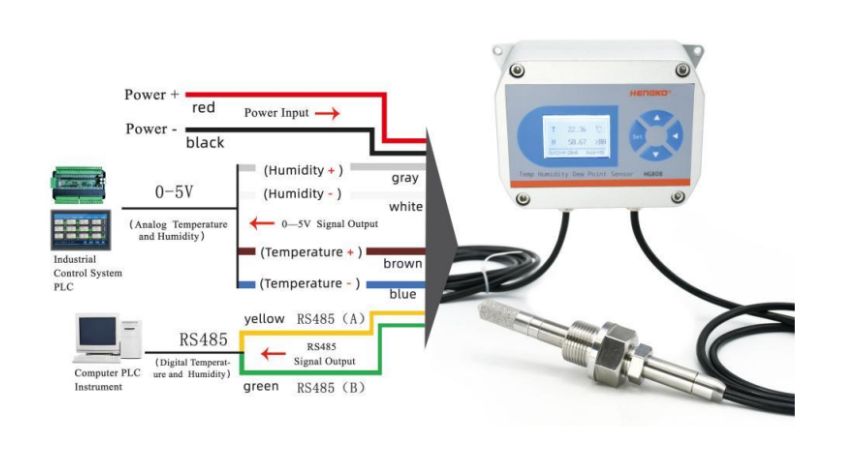

| Line Color | Definition | Specification |

|---|---|---|

| Power Cord | ||

| Red | Power supply positive | 10 ~ 30V DC |

| Black | Power supply negative | GND |

| Analog Output Lines | ||

| Brown | Temperature signal positive | 4-20mA output |

| Blue | Temperature signal negative | Connects to Black (GND) |

| Grey | Humidity signal positive | 4-20mA output |

| White | Humidity signal negative | Connects to Black (GND) |

| RS485 Wiring | ||

| Yellow | RS485A | Twisted pair cable |

| Green | RS485B | Twisted pair cable |

Additional Notes:

Important:

Industrial processes often involve extreme temperatures and humidity levels. Regular transmitters can’t handle these harsh conditions. Here’s a breakdown of applications where high-temperature and humidity transmitters (operating over 100°C and down to -40°C) are crucial:

These are just a few examples. High-temperature and humidity transmitters play a vital role in various industries by ensuring process control, product quality, and safety in extreme environments.

The HG808-H series temperature and humidity transmitter features a high-precision, durable humidity sensor with ±1.5% RH accuracy, making it ideal for harsh industrial environments with temperatures ranging from -50°C to +150°C. This series ensures effective dust-free and clean measurement, making it perfect for clean room applications.

Common uses include electronic and pharmaceutical clean rooms, hospital operating rooms, and various industrial settings such as chemical and paint workshops, agricultural engineering, and HVAC systems. The HG808-H series is also suitable for climate chambers, meteorological stations, museums, and more, where strict temperature and humidity control is essential.

For any specific measurement needs not addressed by the HG808-H series, please contact our customer service for alternative options. Thank you for considering our products!

Split/pipeline type probes with strong anti pollution and oil resistance capabilities.

Simultaneously supporting RS485 output and two analog outputs.

Analog output with 15 high-resolution bits, digital output with optional resolution of 0.1 or 0.01.

Supports single register and multi register reading.

The product has anti condensation function, which can keep the sensor synchronized in high humidity

environments.

Digital output can simultaneously read dew point, humidity, temperature, and PPM values.

Adopting the standard Modbus RTU protocol, it can easily achieve interconnection with PLC, DCS, and

various configuration software.

10V~28V ultra wide voltage input, over current protection, power polarity protection, industrial grade ESD

safety protection, and power supply anti reverse connection function.

In air separation nitrogen generation systems, high-purity gas output depends on more than just core components like compressors, dryers, and PSA towers. One often-overlooked factor

Introduction Glove boxes, also known as inert atmosphere boxes or isolation chambers, play a vital role in laboratories and industrial environments where contamination control is

In the demanding environment of the paper manufacturing industry, high humidity is not just common—it’s unavoidable. From the pulping stage to the drying process and

Introduction In the highly sensitive world of semiconductor manufacturing, where even a minor environmental fluctuation can compromise millions of dollars’ worth of product, precise control

In the modern age of technological advancements, the demand for batteries—especially lithium-ion batteries—has skyrocketed. These energy sources are integral to a wide range of applications,

Introduction Temperature and humidity sensors play a crucial role in various industries, including environmental monitoring, HVAC systems, industrial automation, and agriculture. However, over time, these

HENGKO is a prominent supplier of temperature and humidity monitoring solutions for various industries, specializing in manufacturing advanced temperature and humidity transmitters and sensors.

WhatsApp us